Carbon-coated ferroferric oxide core-shell nano particle and preparation method thereof

A technology of carbon-coated ferroferric oxide and nanoparticles, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem of low saturation magnetization, large product particle size, adsorption Insufficient and other problems, to achieve the effect of high saturation magnetization, simple operation, good magnetic separation and high adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

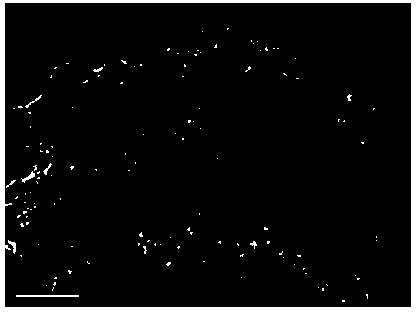

[0021] 12.0 g FeCl 3 ·6H 2 O and 6.0 g FeSO 4 ·7H 2 Add the mixture of O to 50 mL deionized water, stir until it is completely mixed, then add 6.0 g of glucose and wait for it to dissolve completely, slowly add 10 g of ammonia water to the above solution while stirring to make it evenly mixed, and transfer to the polytetrafluoroethylene In the ethylene liner, put the sealed polytetrafluoroethylene liner into a hydrothermal kettle for 10 hours at 180° C. to react for 10 hours, cool to room temperature, wash, and dry to obtain carbon-coated ferric oxide nanoparticles. The transmission electron microscope photographs of the prepared materials are as follows: figure 1 It can be seen that the particle size distribution of ions is relatively uniform. The XRD spectrum of the prepared material is as follows figure 2 As shown, the crystallinity is better. The hysteresis curves of the prepared materials are as follows image 3 As shown, the saturation magnetization is 44.1 emu / ...

Embodiment 2

[0023] 6.0 g FeCl 3 ·6H 2 O and 3.0 g FeSO 4 ·7H 2 Add the mixture of O to 50 mL of deionized water, stir until it is completely mixed, then add 1.125 g of glucose and wait for it to dissolve completely, then slowly add 3.6 g of ammonia water into the above solution while stirring to make it evenly mixed, and transfer it to a polytetrafluoroethylene In the ethylene liner, put the sealed polytetrafluoroethylene liner into a hydrothermal kettle at 220° C. for 15 hours, cool to room temperature, wash, and dry to obtain carbon-coated ferric oxide nanoparticles.

Embodiment 3

[0025] 8.0 g Fe 2 (SO 4 ) 3 9H 2 O and 4.0 g FeSO 4 ·7H 2 Add the mixture of O to 50 mL of deionized water, stir until it is completely mixed, then add 6.0 g of lactose and wait for it to completely dissolve, then slowly add 7.5 g of ammonia water into the above solution while stirring to make it evenly mixed, and transfer it to a polytetrafluoroethylene In the ethylene liner, put the sealed polytetrafluoroethylene liner into a hydrothermal kettle at 150°C for 8 hours, cool to room temperature, wash, and dry to obtain carbon-coated ferric oxide nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com