High-efficiency and long-life stranded electrode wire for wire electric discharge cutting

A technology of electric discharge wire and electrode wire, which is applied in the direction of electrode manufacturing, electric processing equipment, metal processing equipment, etc., can solve the problems of poor chip removal ability, less working fluid, and the cost of easy wire breakage, so as to reduce the probability of wire breakage, Improve the cutting speed and solve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and example the present invention will be further described

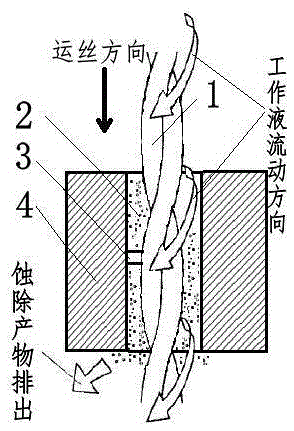

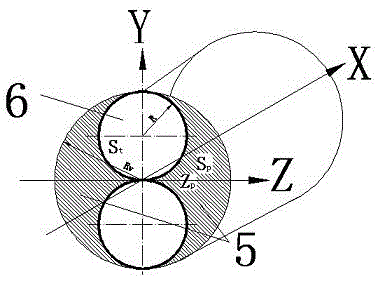

[0019] like Figure 1-2 shown.

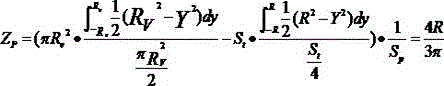

[0020] A twisted electrode wire for wire electric discharge cutting, which consists of two or more electrode wires that are twisted by a twisting mechanism to form a twist-like structure, and a wire that can carry working fluid and erode is formed in the depression of the twist-like structure. In addition to the chip space where the product is taken out of the processing space, the raised part of the twist-shaped structure is more likely to form a discharge point, which improves the explosive erosion ability. The material of each electrode wire can be the same or different. When the material is the same, the discharge rate can be the same or different. The diameter of each electrode wire can be the same or different. The diameter of the same electrode wire can also be the same or different. .

[0021] exist figure 1 In the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com