Method for preparing copper zinc tin sulfide thin film on flexible substrate through magnetron sputtering method

A flexible substrate, magnetron sputtering technology, applied in the direction of climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc., to achieve the effect of improving density, reducing secondary phases, and improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

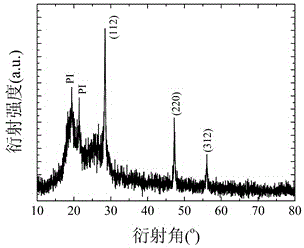

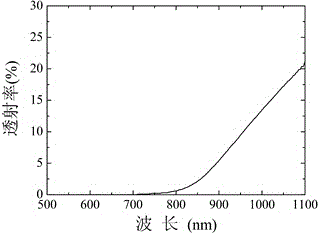

[0027] Use flexible polyimide as the substrate material. After ultrasonic cleaning with acetone, ethanol and deionized water, dry N 2 Blow dry and put into a magnetron sputtering vacuum chamber. First evacuate the vacuum chamber to a background vacuum of 4×10 -4 Pa, then pass high-purity Ar as the working gas, the flow rate of Ar is 20ml / min, and the working pressure is 0.5Pa. The Cu target, Zn target and Sn target were pre-sputtered for 5 minutes to remove impurities on the surface of the target. Then proceed to the formal sputtering coating, first DC sputtering Zn, then radio frequency sputtering Sn, and finally DC sputtering Cu, the sputtering time of Zn, Sn, and Cu are 92 seconds, 2173 seconds and 221 seconds, respectively. It is 50W, 50W and 40W, so as to realize the deposition of Cu-Zn-Sn metal stack on the polyimide substrate as the precursor of the copper-zinc-tin-sulfur film. The precursor is then vulcanized. The vulcanization source material is solid sulfur powder wi...

Embodiment 2

[0029] Use flexible polyimide as the substrate material. After ultrasonic cleaning with acetone, ethanol and deionized water, dry N 2 Blow dry and put into a magnetron sputtering vacuum chamber. First evacuate the vacuum chamber to a background vacuum of 4×10 -4 Pa, then pass high-purity Ar as the working gas, the flow rate of Ar is 20ml / min, and the working pressure is 0.5Pa. The Cu target, Zn target and Sn target were pre-sputtered for 5 minutes to remove impurities on the surface of the target. Then proceed to the formal sputtering coating, first DC sputtering Zn, then radio frequency sputtering Sn, and finally DC sputtering Cu, the sputtering time of Zn, Sn, and Cu are 92 seconds, 2173 seconds and 221 seconds, respectively. It is 50W, 50W and 40W, so as to realize the deposition of Cu-Zn-Sn metal stack on the polyimide substrate as the precursor of the copper-zinc-tin-sulfur film. The precursor is then vulcanized. The vulcanization source material is solid sulfur powder wi...

Embodiment 3

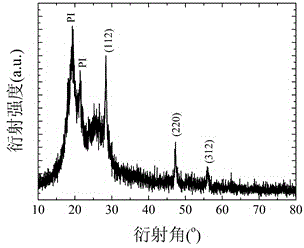

[0031] The flexible molybdenum foil is used as the substrate material. After ultrasonic cleaning with acetone, ethanol and deionized water, dry N 2 Blow dry and put into a magnetron sputtering vacuum chamber. First evacuate the vacuum chamber to a background vacuum of 4×10 -4 Pa, then pass high-purity Ar as the working gas, the flow rate of Ar is 20ml / min, and the working pressure is 0.5Pa. The Cu target, Zn target and Sn target were pre-sputtered for 5 minutes to remove impurities on the surface of the target. Then proceed to the formal sputtering coating, first DC sputtering Zn, then radio frequency sputtering Sn, and finally DC sputtering Cu, the sputtering time of Zn, Sn, and Cu are 92 seconds, 2173 seconds and 221 seconds, respectively. It is 50W, 50W and 40W, so as to realize the deposition of Cu-Zn-Sn metal stack on the molybdenum foil substrate as the precursor of the copper-zinc-tin-sulfur film. The precursor is then vulcanized. The vulcanization source material is so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com