Quantity-controllable dry packaging equipment for mandarin orange coarse grain powder

A technology for packaging equipment and coarse grain powder, which is applied in the field of dry packaging equipment for tangerine coarse grain powder, can solve the problems of long time consumption, low work efficiency, multi-manpower, etc., and achieves the effect of reducing operation trouble, improving work efficiency and reducing burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

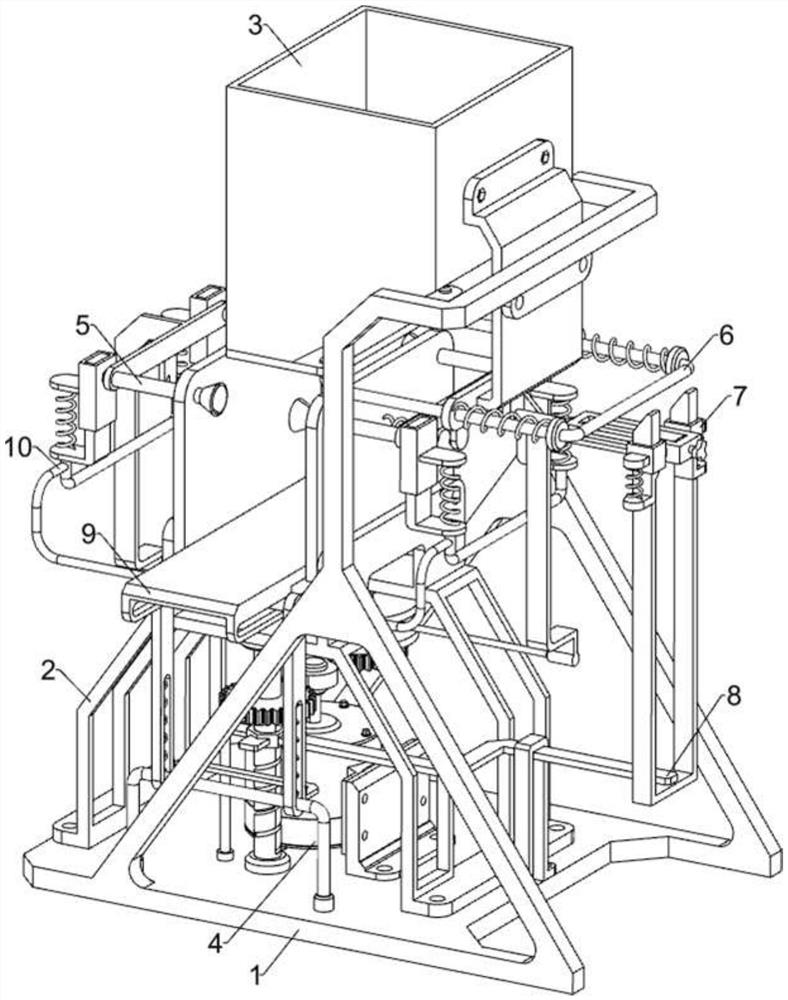

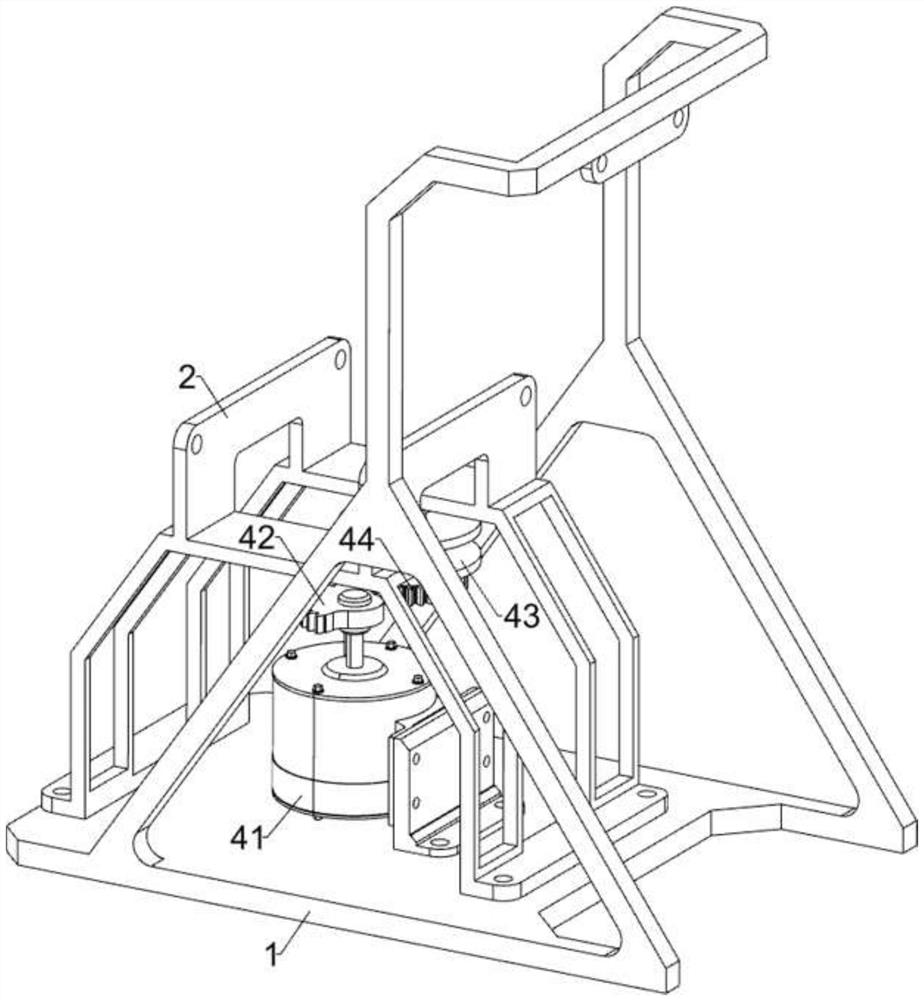

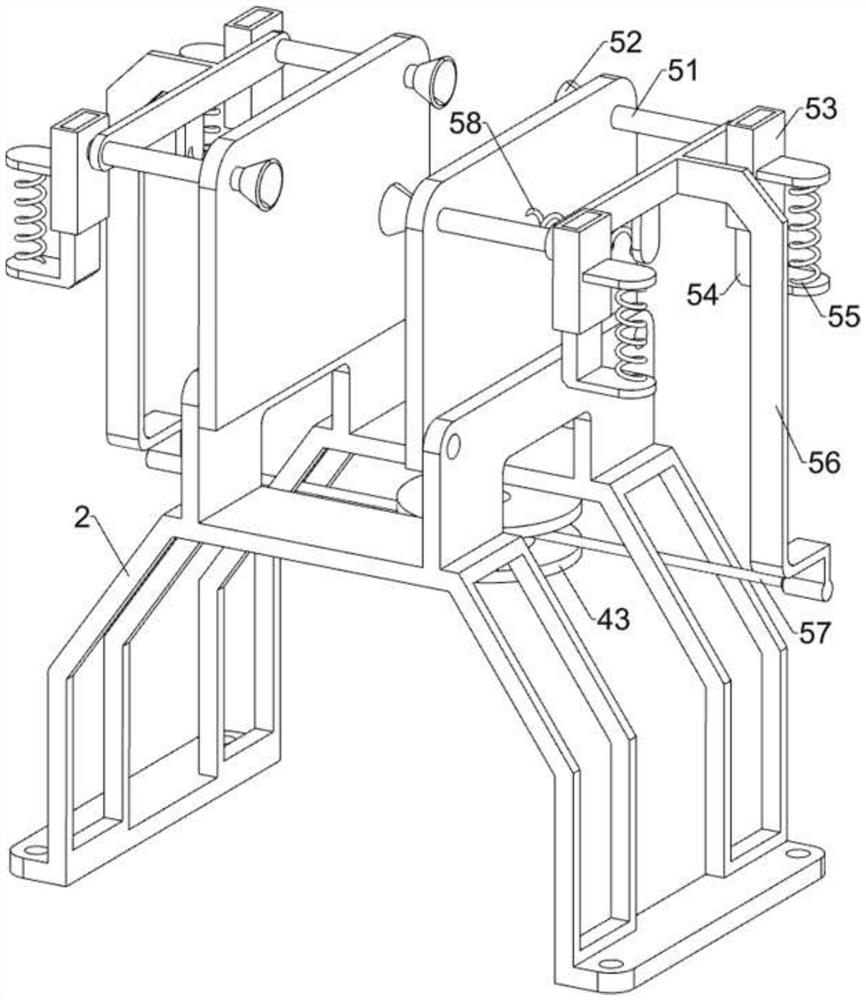

[0029] A controllable amount of tangerine coarse grain powder dry packaging equipment, such as Figure 1 to Figure 4 As shown, it includes a frame 1, a support frame 2, a storage frame 3, a drive assembly 4, an opening assembly 5 and a blocking assembly 6. The left side of the frame 1 is fixed with the support frame 2 by bolts. A storage frame 3 is fixedly connected to the upper side by bolts, a drive assembly 4 is arranged between the frame 1 and the support frame 2 , an opening assembly 5 is arranged on the support frame 2 , and a blocking assembly 6 is arranged on the frame 1 .

[0030] When the dried mandarin coarse grain powder needs to be packaged, place the dried mandarin coarse grain powder in the storage frame 3, while the blocking component 6 will prevent the dried mandarin coarse grain powder from falling, and then place the packaging bag on the opening component 5 Then start the driving component 4, the driving component 4 will drive the opening component 5 to oper...

Embodiment 2

[0038] On the basis of Example 1, as figure 1 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, it also includes a push assembly 7. The push assembly 7 includes a fixed rod 71, a slide rail 72, a slider 73, a first screw rod 74, a guide frame 75, a push plate 76 and a fourth spring 77. The right side connecting frame The right side of 56 is welded with a fixed rod 71, the right side of the fixed rod 71 is provided with a slide rail 72, the slide rail 72 is slidably provided with a slider 73, and the slide rail 72 is rotatably connected with a first screw rod 74, the first The screw rod 74 is connected with the sliding block 73 through threads. The front and rear sides of the sliding block 73 are provided with guide frames 75 , and a push plate 76 is slidably connected between the guide frames 75 , and both the push plate 76 and the guide frame 75 are connected. There is a fourth spring 77 .

[0039] When the connecting frame 56 moves inward, the fixed rod 71 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com