Anti-corrosion wear-proof hydraulic cylinder and manufacturing method thereof

A hydraulic cylinder, anti-corrosion and wear-resistant technology, applied in the field of hydraulic cylinders, can solve the problems of hydraulic cylinders without good wear resistance and anti-corrosion performance, reduce the service life of hydraulic cylinders, and reduce the working efficiency of hydraulic cylinders, so as to improve process performance and improve Combination, the effect that is conducive to a wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

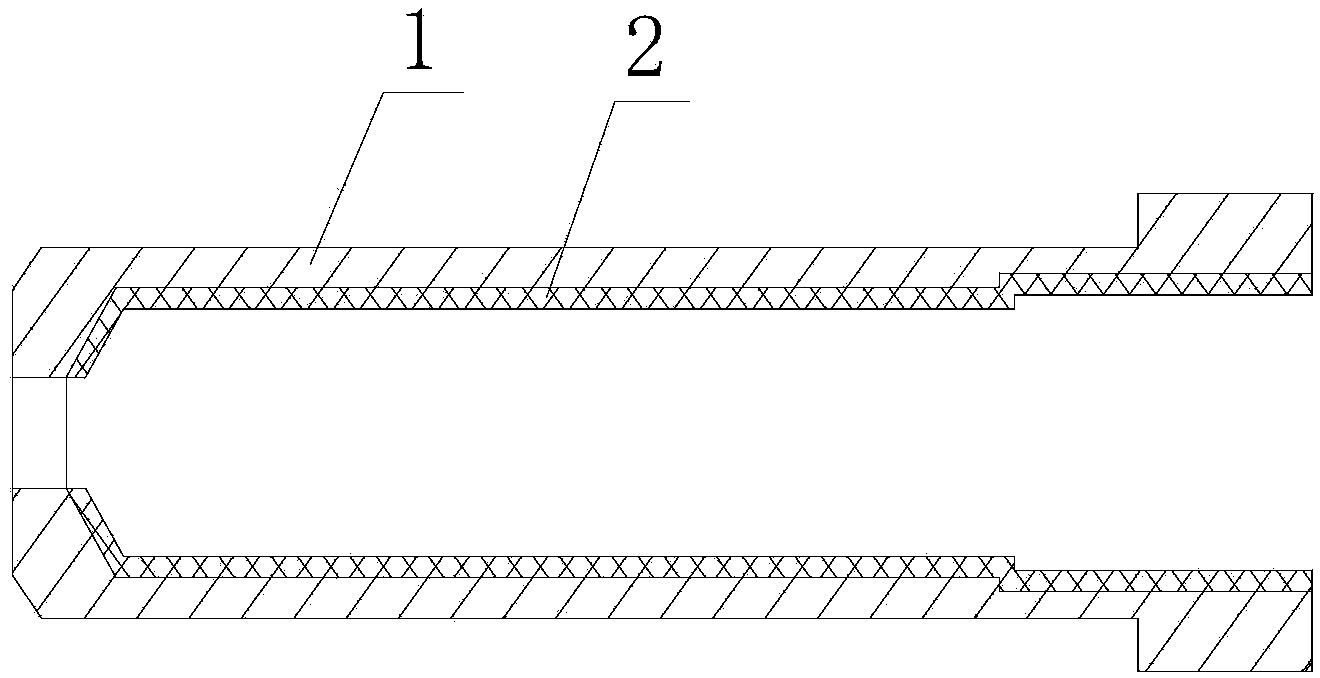

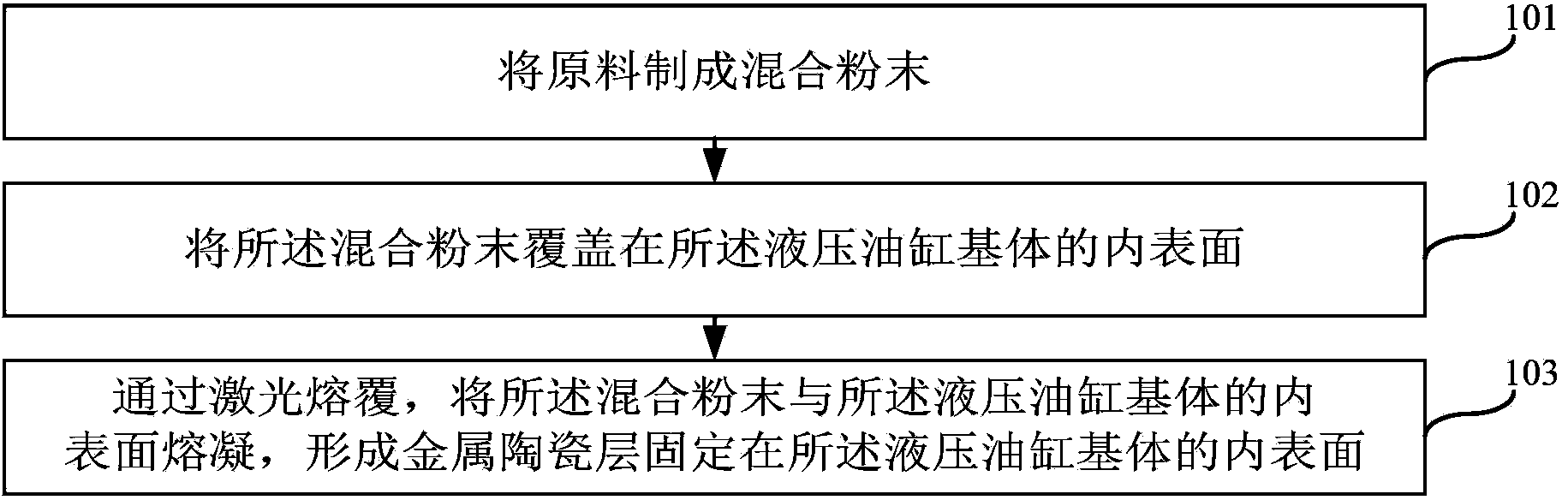

[0092] In terms of mass percentage, 10% of chromium, 3% of silicon, 40% of iron, and 12% of carbon are made into a mixed powder with a particle size of 150 mesh, and the mixed powder is covered on the inner surface of the hydraulic cylinder base 1 made of No. 45 steel on, use the CO 2 The laser is used for cladding, the wavelength of the laser is 1000nm, and the energy density is 60J / mm 2 ; The irradiation time was 4 minutes. After the irradiation is completed, the formed cermet layer 2 is fused with the inner surface of the 45# steel hydraulic cylinder substrate 1, and its thickness is about 1mm, and then it can be formed by post-stage heat treatment.

specific Embodiment 2

[0093] In terms of mass percentage, 10% of chromium, 7% of silicon, 30% of iron, and 8% of carbon are made into a mixed powder with a particle size of 200 meshes, and the mixed powder is covered on the inner surface of the hydraulic cylinder base 1 made of No. 45 steel on, use the CO 2Laser cladding, where the wavelength of the laser is 1060nm, and the energy density is 70J / mm 2 ; The irradiation time is 5 minutes. After the irradiation is completed, the formed cermet layer 2 is fused with the inner surface of the hydraulic cylinder base 1 of No. 45 steel, and its thickness is about 1.2mm, and then it can be formed by post-stage heat treatment.

specific Embodiment 3

[0094] In terms of mass percentage, 13% of chromium, 6% of silicon, 32% of iron, 13% of carbon, and 36% of nickel are made into a mixed powder with a particle size of 220 mesh, and the mixed powder is covered on the hydraulic cylinder base made of No. 45 steel 1 on the inner surface, using CO 2 Laser cladding, where the wavelength of the laser is 1040nm, and the energy density is 65J / mm 2 ; The irradiation time is 6 minutes. After the irradiation is completed, the formed cermet layer 2 is fused with the inner surface of the hydraulic cylinder base 1 of No. 45 steel, and its thickness is about 1.3mm, and then it can be formed by post-stage heat treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com