Method for preparing binderless BaTiO3 ceramic through microwave-assisted method

A binder-free, microwave-assisted technology, applied in the field of preparation of binder-free ceramics, can solve the problems of ceramic grain growth, easy formation of pores, complex operation, etc., achieve short reaction cycle, no temperature gradient, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

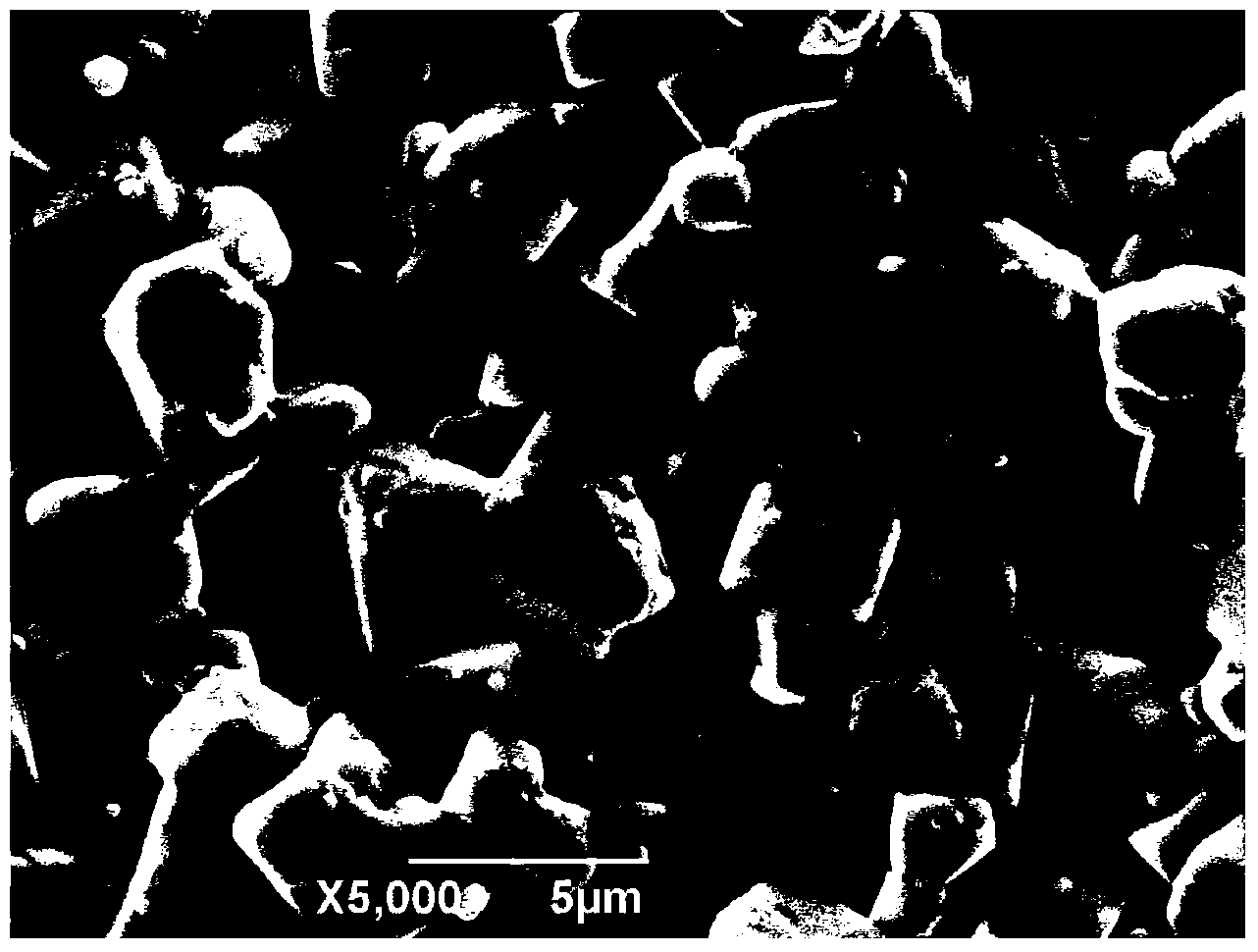

Image

Examples

Embodiment 1

[0021] 1) BaCl 2 ·H 2 O and TiCl 4 Dissolve completely in deionized water at 0.3mol / L and 0.6mol / L, press [NaOH] / [TiCl 4 ]=10 Add mineralizer NaOH, stir evenly, obtain co-precipitation precursor A;

[0022] 2) Pour the co-precipitation precursor A into the lining of the microwave hydrothermal reaction kettle, then put the lining into the hydrothermal kettle, set the reaction temperature to 180°C, and the reaction time to 30 minutes;

[0023] 3) After the furnace temperature was naturally cooled to room temperature, the reactant was taken out, washed several times with deionized water, and then dried at 80°C. The final nano-BaTiO 3 Powder;

[0024] 4) For the obtained BaTiO 3 The powder is first manually compacted, and the obtained BaTiO 3 The block is sieved and granulated through a 200-300-mesh sieve to obtain a powder with a particle size of 75-48 μm, and the obtained powder is molded at 100 MPa (Φ12mm×1.2mm);

[0025] 5) Sinter the formed green body in a microwave si...

Embodiment 2

[0027] 1) BaCl 2 ·H 2 O and TiCl 4 Dissolve completely in deionized water at 0.3mol / L and 0.5mol / L, press [NaOH] / [TiCl 4 ]=9 Add mineralizer NaOH, stir evenly, obtain co-precipitation precursor A;

[0028] 2) Pour the co-precipitation precursor A into the lining of the microwave hydrothermal reaction kettle, then put the lining into the hydrothermal kettle, set the reaction temperature to 200°C, and the reaction time to 30 minutes;

[0029] 3) After the furnace temperature was naturally cooled to room temperature, the reactants were taken out, washed several times with deionized water, and then dried at 70°C. The final nano-BaTiO 3 Powder;

[0030] 4) For the obtained BaTiO 3 The powder is first manually compacted, and the obtained BaTiO 3 The block is sieved and granulated through a 230-270 mesh sieve to obtain a powder with a particle size of 63-53 μm, and the obtained powder is molded at 90 MPa (Φ12mm×1.2mm);

[0031] 5) Sinter the formed green body in a microwave si...

Embodiment 3

[0033] 1) BaCl 2 ? h 2 O and TiCl 4 Dissolve completely in deionized water at 0.3mol / L and 0.6mol / L, press [NaOH] / [TiCl 4 ]=11 Add mineralizer NaOH, stir evenly, obtain co-precipitation precursor A;

[0034] 2) Pour the co-precipitation precursor A into the lining of the microwave hydrothermal reaction kettle, then put the lining into the hydrothermal kettle, set the reaction temperature to 200°C, and the reaction time to 40min;

[0035] 3) After the furnace temperature was naturally cooled to room temperature, the reactants were taken out, washed several times with deionized water, and then dried at 75°C. The final nano-BaTiO 3 Powder;

[0036] 4) For the obtained BaTiO 3 The powder is first manually compacted, and the obtained BaTiO 3 The block is sieved and granulated through a 200-230 mesh sieve to obtain a powder with a particle size of 75-63 μm, and the obtained powder is molded at 95 MPa (Φ12mm×1.2mm);

[0037] 5) Sinter the formed green body in a microwave sint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com