Method for preparing doping porous silicon ball

A technology of porous silicon and silicon spheres, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., to achieve uniform morphology, accelerated reaction process, and good industrial value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

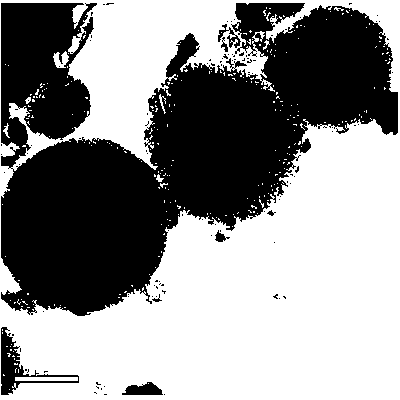

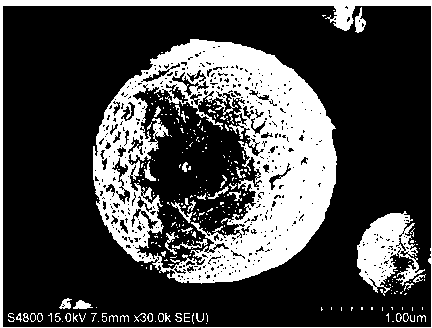

[0036] This embodiment provides a method for preparing nanoporous silicon using doped silicon spheres. When using doped silicon spheres as a raw material, chemical etching is used to prepare nanoporous silicon. The specific steps are as follows:

[0037] 1) The boron doping concentration is selected to be 5.09×10 19 atoms / cm 3 (Conductivity 0.002~0.0025Ω·cm) P-type single crystal silicon master alloy is used as raw material, processed by pulse discharge method, processing parameters are: open circuit voltage 100V; peak current 5A; pulse width 50μs; duty ratio 1:2, The working fluid is deionized water, and the electrodes are copper electrodes. Process and collect doped silicon spheres, the particle size range of silicon spheres is 0.1-2 μm, the size is concentrated at 1 μm, and the concentration is greater than 90%.

[0038] 2) Measure 10g of silicon spheres as the base material;

[0039] 3) Clean the surface of the silicon ball with a chemical solution, the solution is 5% h...

Embodiment 2

[0050] This embodiment provides a method for preparing nanoporous silicon using doped silicon spheres. When using doped silicon spheres as a raw material, chemical etching is used to prepare nanoporous silicon. The specific steps are as follows:

[0051] 1) The phosphorus doping concentration is selected as 2.02×10 15 atoms / cm 3 N-type single crystal silicon ingot (conductivity 1~3Ω·cm) is used as raw material, processed by pulse discharge method, processing parameters are: open circuit voltage 150V; peak current 10A; pulse width 100μs; duty ratio 1:5, working fluid For deionized water, the electrode is a copper electrode. Process and collect doped silicon spheres, the particle size range of silicon spheres is 1-10 μm, the size is concentrated at 5 μm, and the concentration is greater than 90%.

[0052] 2) Measure 10g of silicon spheres as the base material;

[0053] 3) Clean the surface of the silicon ball with a chemical solution, the solution is 10% hydrofluoric acid sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com