A processing method of fine-grained superplastic ta15 titanium alloy sheet

A processing method and titanium alloy technology, applied in the direction of metal rolling, metal rolling stand, metal rolling stand, etc., can solve the problems of small cold rolling deformation, high processing cost, low superplasticity, etc., and achieve horizontal Small difference in longitudinal properties, high structure uniformity, and improved rolling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

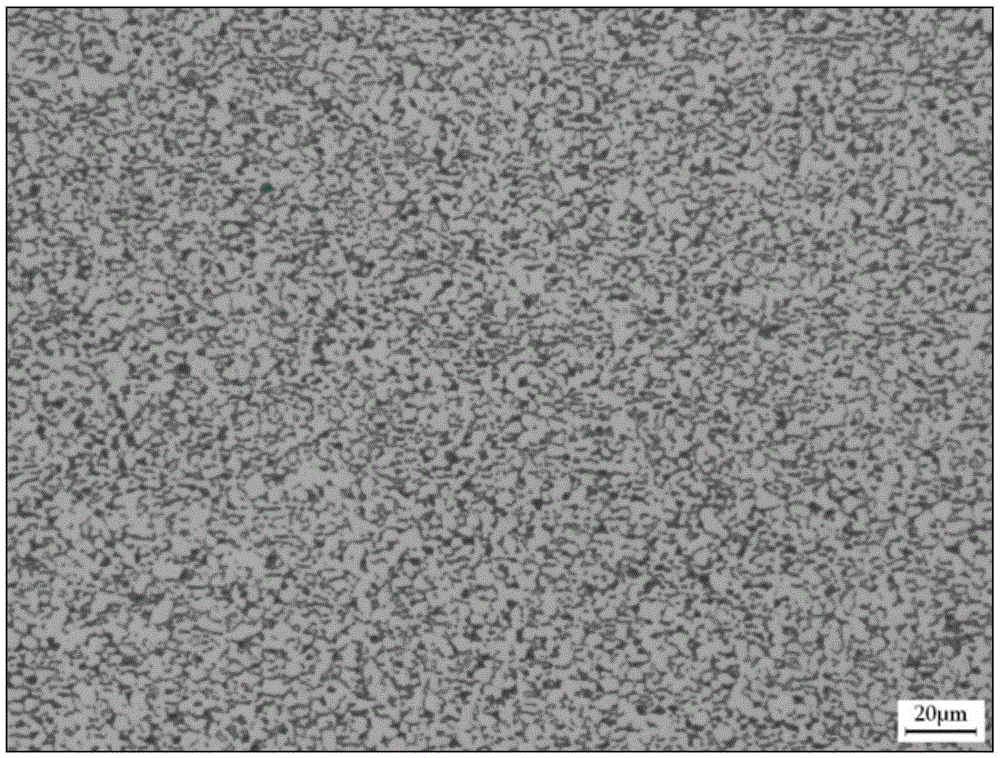

Image

Examples

Embodiment 1

[0030] The processing method of the present embodiment fine-grained superplastic TA15 titanium alloy thin plate comprises the following steps:

[0031] Step 1. Place a TA15 titanium alloy slab with a thickness of 48mm in a heating furnace and keep it warm for 65min at a temperature of 920°C;

[0032] Step 2. The TA15 titanium alloy slab after heat preservation in step 1 is sent to the hot rolling mill for the first rolling. The specific process is: first pass the processing rate of 25%, 21.5%, 20.5%, and 20%. The thickness of the TA15 titanium alloy slab is rolled to 18mm, and then the thickness of the TA15 titanium alloy slab is rolled to 9mm with a pass processing rate of 19%, 17.5%, 14.5%, and 12%, to obtain the first semi-finished slab; The first rolling is unidirectional rolling;

[0033] Step 3, placing the first semi-finished slab described in step 2 in a heating furnace, and keeping it warm for 18 minutes at a temperature of 900° C.;

[0034]Step 4. The first semi-fi...

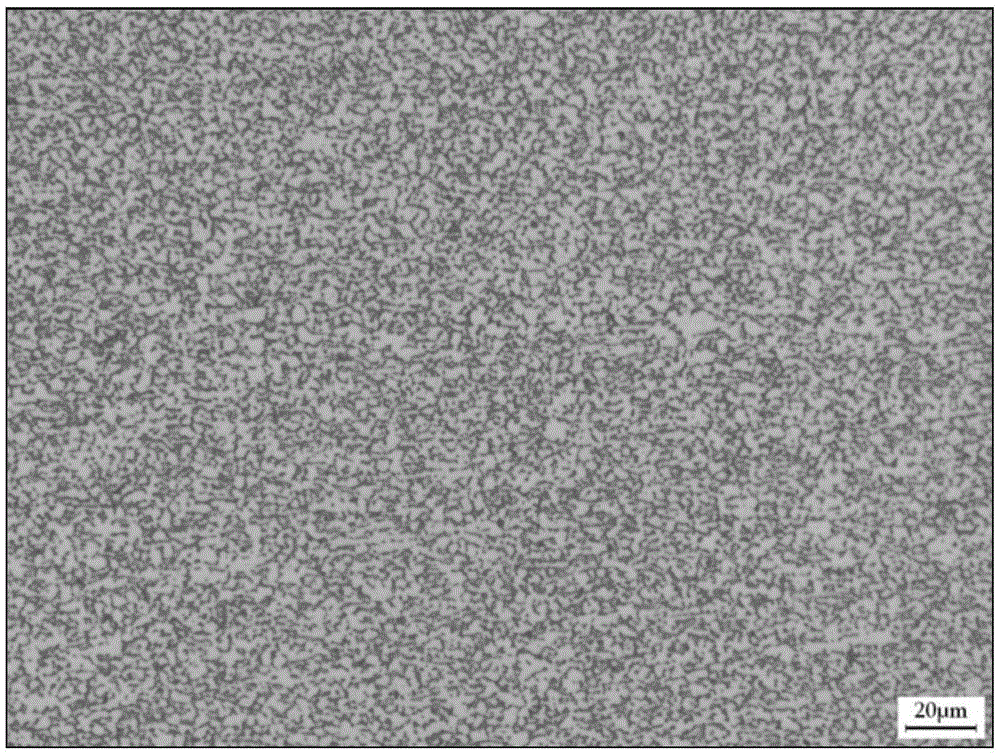

Embodiment 2

[0040] The processing method of the present embodiment fine-grained superplastic TA15 titanium alloy thin plate comprises the following steps:

[0041] Step 1. Place a TA15 titanium alloy slab with a thickness of 50mm in a heating furnace and keep it warm for 65min at a temperature of 910°C;

[0042] Step 2: Send the TA15 titanium alloy slab after heat preservation in step 1 into the hot rolling mill for first rolling. The thickness of the TA15 titanium alloy slab is rolled to 19mm, and then the thickness of the TA15 titanium alloy slab is rolled to 10mm with a pass processing rate of 18%, 15%, 14%, and 12%, to obtain the first semi-finished slab; The first rolling is unidirectional rolling;

[0043] Step 3, placing the first semi-finished slab described in step 2 in a heating furnace, and keeping it warm for 20 minutes at a temperature of 890°C;

[0044] Step 4. The first semi-finished slab after heat preservation in step 3 is sent to the hot rolling mill for second rolling...

Embodiment 3

[0050] The processing method of the present embodiment fine-grained superplastic TA15 titanium alloy thin plate comprises the following steps:

[0051] Step 1. Place a TA15 titanium alloy slab with a thickness of 54mm in a heating furnace and keep it warm for 70min at a temperature of 930°C;

[0052] Step 2. The TA15 titanium alloy slab after heat preservation in step 1 is sent to the hot rolling mill for the first rolling. The specific process is: first with 25%, 22.5%, 21%, 20% pass processing rate The thickness of the TA15 titanium alloy slab is rolled to 19.8mm, and then the thickness of the TA15 titanium alloy slab is rolled to 10mm with the pass processing rate of 18%, 16.5%, 15%, and 13%, to obtain the first semi-finished slab ; The first rolling is unidirectional rolling;

[0053] Step 3, placing the first semi-finished slab described in step 2 in a heating furnace, and keeping it warm for 25 minutes at a temperature of 890°C;

[0054] Step 4. The first semi-finished...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com