Asymmetric chitosan nanofiber porous membrane and preparation method thereof

A chitosan nano, asymmetric technology, applied in medical science, bandages, absorbent pads, etc., can solve the problems of complex preparation process, interfacial interaction strength affecting material properties, damage to pore structure and porosity, etc., and achieve a simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Dissolve 1 g of chitosan in 100 ml of 2% acetic acid aqueous solution, and defoam.

[0026] 2. Take 8g of chitosan solution and move it to a low-temperature freezer at -20°C, and freeze for 12 hours to perform thermal phase separation.

[0027] 3. Pour 1% NaOH coagulation solution into the above sol, soak for 6 hours, solidify and regenerate to form a film.

[0028] 4. Wash the membrane sample with distilled water until neutral, freeze at -23°C for 4 hours, and freeze-dry at -50°C for 48 hours to obtain an asymmetric chitosan porous membrane.

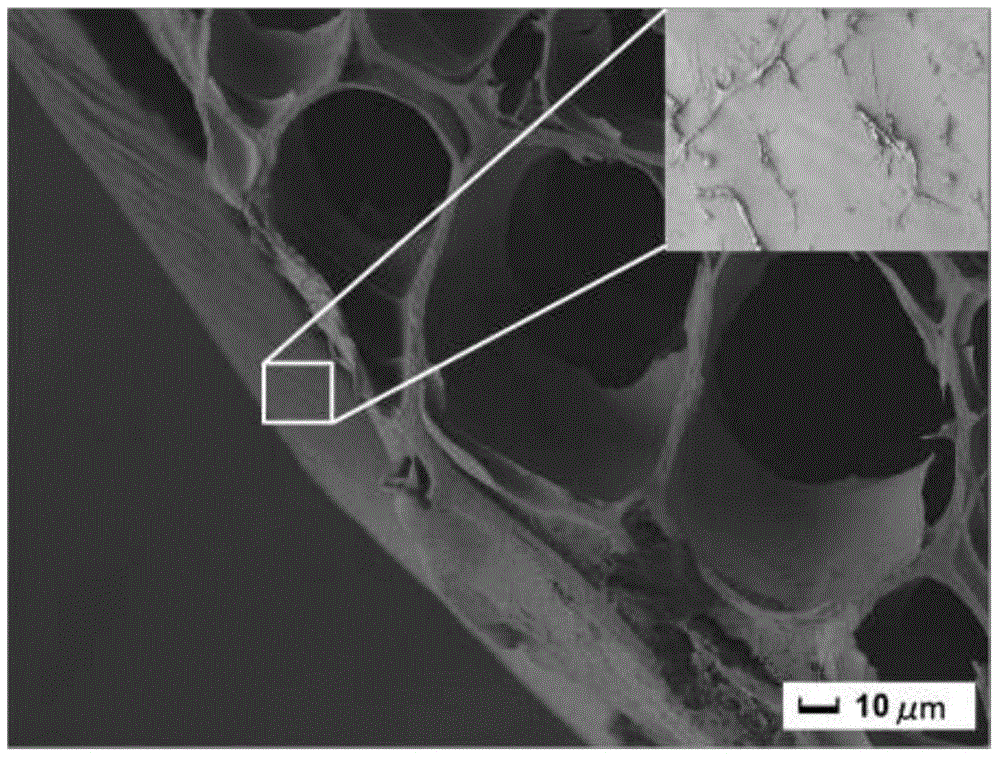

[0029] The upper surface of the asymmetric nanofiber porous membrane prepared in this example is a dense and thick skin layer, the diameter of the pores of the nanofiber layer is 3-6 μm, the fiber diameter is 40-60 nm, the water absorption rate can reach 4000%, and the water retention rate is 250 %, the porosity is 94%.

Embodiment 2

[0031] 1. Dissolve 1 g of chitosan in 100 ml of 2% acetic acid aqueous solution, and defoam.

[0032] 2. Take 8g of chitosan solution and move it to a low-temperature freezer at -20°C for thermally induced phase separation, and freeze for 12 hours.

[0033] 3. Pour 1% Na2CO3 coagulation solution into the above sol, soak for 8 hours, solidify and regenerate to form a film.

[0034] 4. Wash the membrane sample with distilled water until neutral, freeze at -23°C for 4 hours, and freeze-dry at -50°C for 48 hours to obtain an asymmetric chitosan porous membrane.

[0035] In the asymmetric chitosan nanofiber porous membrane prepared in this example, micropores with a pore diameter of 400-500 nm are distributed on the surface of the cortex, the diameter of the pores of the nanofiber membrane layer is 1-2 μm, and the fiber diameter is 50-70 nm. The water absorption rate is 4200%, the water retention rate is 280%, and the porosity is 96%.

Embodiment 3

[0037] 1. Dissolve 3g of chitosan in 100ml of 2% acetic acid aqueous solution and remove foam.

[0038] 2. Take 8g of chitosan solution and move it to a low-temperature freezer at -20°C, and freeze for 12 hours to perform thermal phase separation.

[0039] 3. Pour 1% NaOH coagulation solution into the above sol, soak for 6 hours, solidify and regenerate to form a film.

[0040] 4. Wash the membrane sample with distilled water until neutral, freeze at -23°C for 4 hours, and freeze-dry at -50°C for 48 hours to obtain an asymmetric chitosan porous membrane.

[0041] The asymmetric nanofiber porous membrane prepared in this example has a dense skin layer on the upper surface, the diameter of the pores of the porous nanofiber layer is 2-6 μm, the size of the nanofibers is 30-60 nm, the water absorption rate is 2100%, and the water retention rate is 160 %, the porosity is 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com