Metal heating element with coating and manufacturing method of metal heating element

A heating element and coating technology, which is applied to heating element materials, heating inorganic powder coating, etc., can solve the problems of scaling and cracks easily, and achieve the effect of dense structure, not easy to water, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

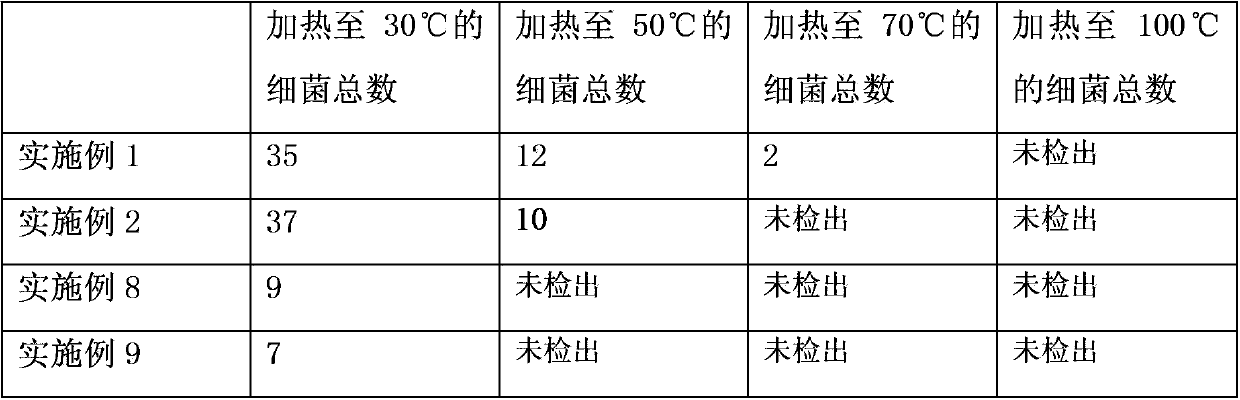

Embodiment 1

[0045] Mix the components of the first coating according to the following mass percentages: the content of silicon oxide is 28%, the content of aluminum oxide is 13%, the content of boron oxide is 44%, the content of calcium oxide is 2%, the content of oxide The content of cobalt is 2%, the content of titanium oxide is 5%, the content of zirconium oxide is 1%, and the content of sodium oxide is 5%; then heated to molten state, cooled, and pulverized.

[0046] By wet spraying, the surface of the stainless steel heating element is covered with a thin, uniform and continuous coating, heated to 900 ° C, kept for 20 minutes; cooled to room temperature, that is. The thickness of this first coating is 100 μm. Example 2

Embodiment 2

[0047] Mix the components of the first coating according to the following mass percentages: the content of silicon oxide is 48%, the content of aluminum oxide is 3%, the content of boron oxide is 30%, the content of calcium oxide is 2%, the content of oxide The content of cobalt is 3%, the content of titanium oxide is 8%, the content of zirconium oxide is 5%, and the content of calcium oxide is 1%; then heated to molten state, cooled, and pulverized.

[0048] Enamel the first coating on the surface of the stainless steel heating element by electrostatic spraying, heat to 800°C and keep it warm for 10 minutes; cool to room temperature to obtain the product. The thickness of this first coating is 10 μm.

Embodiment 3

[0050] Mix the components of the first coating according to the following mass percentages: the content of silicon oxide is 32%, the content of aluminum oxide is 10%, the content of boron oxide is 40%, the content of calcium oxide is 5%, the content of oxide The content of cobalt is 6%, the content of titanium oxide is 2%, the content of zirconium oxide is 2%, and the content of potassium oxide is 3%; then heated to molten state, cooled, and pulverized.

[0051] Apply the first coating on the surface of the stainless steel heating element by electrostatic spraying, heat to 840°C, keep it warm for 15 minutes, and cool to room temperature to obtain the finished product. The thickness of this first coating is 350 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com