Anti-bending composite insulator of bullet train roof

A technology for composite insulators and motor vehicle roofs, applied in insulators, support insulators, electrical components, etc., can solve the problems of poor acid resistance and bending resistance, difficult to meet the requirements of acid resistance and bending resistance, and difficult to operate, etc. Achieve the effect of good seismic performance and high bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

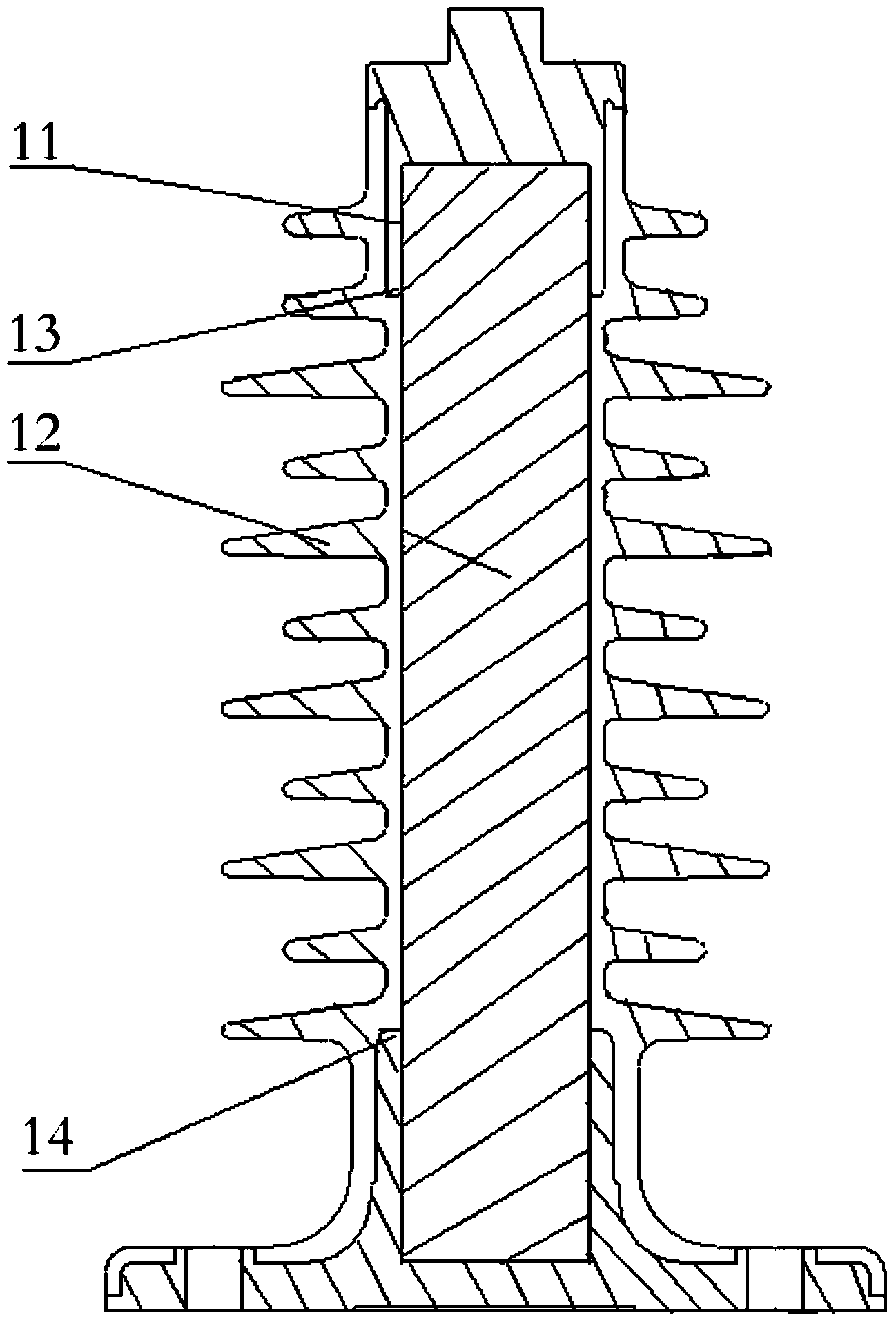

[0030] figure 2 It is a cross-sectional view of the bending-resistant composite insulator on the roof of the motor car provided by the embodiment of the device of the present invention. Such as figure 2 As shown, the bending-resistant composite insulator on the roof of the motor car includes a support body 21, and several groups of sheds 22 arranged side by side in the axial direction are arranged around the side wall of the support body 21, and the shed sheds 22 protrude outward in the radial direction. On the side wall of the support body 21, wherein the support body 21 is a high-strength glass fiber epoxy resin rod.

[0031] The support body 21 is the skeleton of a composite insulator. Since this solution uses high-strength glass fiber epoxy resin rods as the support body 21, it has relativel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com