Polyimide aerogel having infrared radiation resisting property and preparation method thereof

A radiation characteristic and polyimide technology, which is applied in the field of airgel with anti-infrared radiation characteristics and its preparation, can solve the problem of low density, weak thermal radiation resistance and reduced heat insulation performance of polyimide airgel and other problems, to avoid a sharp increase in thermal conductivity, good flexibility and mechanical properties, and expand the use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

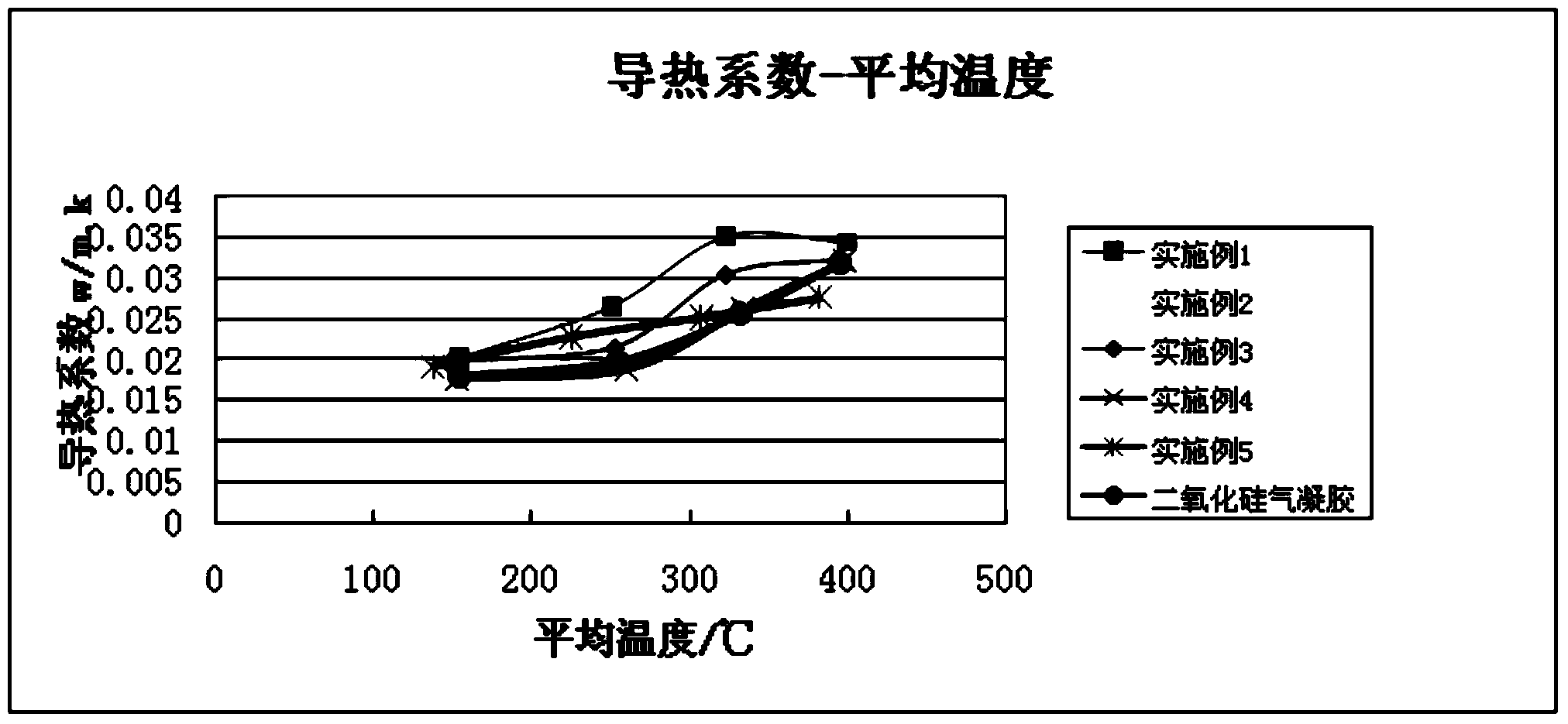

Examples

Embodiment 1

[0041] A preparation method of polyimide airgel with anti-infrared radiation characteristics, comprising the steps of:

[0042] (1) The reactor is dehydrated, and the vacuum is set below <40Pa;

[0043] (2) Under the protection of an inert gas, PMDA and ODA are put into a reactor at a molar ratio of 1:1.0 to carry out a polymerization reaction. The conditions of the polymerization reaction are: the temperature is controlled at 25° C., stirred for 5 hours, and a lyosol is formed;

[0044] (3) Add nano-carbon airgel micropowder according to 3% of the sol mass, and use ultrasonic vibration for 30min to measure the intrinsic viscosity of the mixed solution sol to be 0.8418g / dL;

[0045] (3) inject the mixed liquid sol into the mould, and age for 48 hours to obtain a gel;

[0046] (4) Place the gel in the reactor, introduce acetone to immerse the gel, and keep the vacuum below <40Pa for pressure impregnation for 4 hours;

[0047] (5) Discard the solvent, then vacuumize the solven...

Embodiment 2

[0050] A preparation method of polyimide airgel with anti-infrared radiation characteristics, comprising the steps of:

[0051](1) The reactor is dehydrated, and the vacuum is set below <40Pa;

[0052] (2) Under the protection of an inert gas, PMDA and ODA are put into a reactor at a molar ratio of 1:1.0 to carry out a polymerization reaction. The conditions of the polymerization reaction are: the temperature is controlled at 25° C., stirred for 5 hours, and a lyosol is formed;

[0053] (3) Add nano-titanium dioxide gel micropowder according to 3% of the sol mass, and use ultrasonic vibration for 30min to measure the intrinsic viscosity of the mixed solution sol to be 0.8402g / dL;

[0054] (3) inject the mixed liquid sol into the mould, and age for 48 hours to obtain a gel;

[0055] (4) Place the gel in the reactor, introduce acetone to immerse the gel, and keep the vacuum below <40Pa for pressure impregnation for 4 hours;

[0056] (5) Discard the solvent, then vacuumize the ...

Embodiment 3

[0059] A preparation method of polyimide airgel with anti-infrared radiation characteristics, comprising the steps of:

[0060] (1) The reactor is dehydrated, and the vacuum is set below <40Pa;

[0061] (2) Under the protection of an inert gas, PMDA and ODA are put into a reactor at a molar ratio of 1:1.0 to carry out a polymerization reaction. The conditions of the polymerization reaction are: the temperature is controlled at 25° C., stirred for 5 hours, and a lyosol is formed;

[0062] (3) Add nano-iron oxide airgel micropowder and nano-alumina airgel micropowder (1:1 ratio) according to 3% of the sol mass, and use ultrasonic vibration for 30min to measure the intrinsic viscosity of the mixed solution sol as 0.8518g / dL;

[0063] (3) inject the mixed liquid sol into the mould, and age for 48 hours to obtain a gel;

[0064] (4) Place the gel in the reactor, introduce acetone to immerse the gel, and keep the vacuum below <40Pa for pressure impregnation for 4 hours;

[0065] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com