High-performance permanent magnet ferrite material and preparing method thereof

A permanent magnet ferrite, high-performance technology, applied in the field of magnetic functional material preparation, can solve the problems of high cost, complicated preparation process, unfavorable industrial production, etc., to achieve the effect of improving efficiency, reducing sintering temperature, and avoiding difficulties in forming magnetic parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

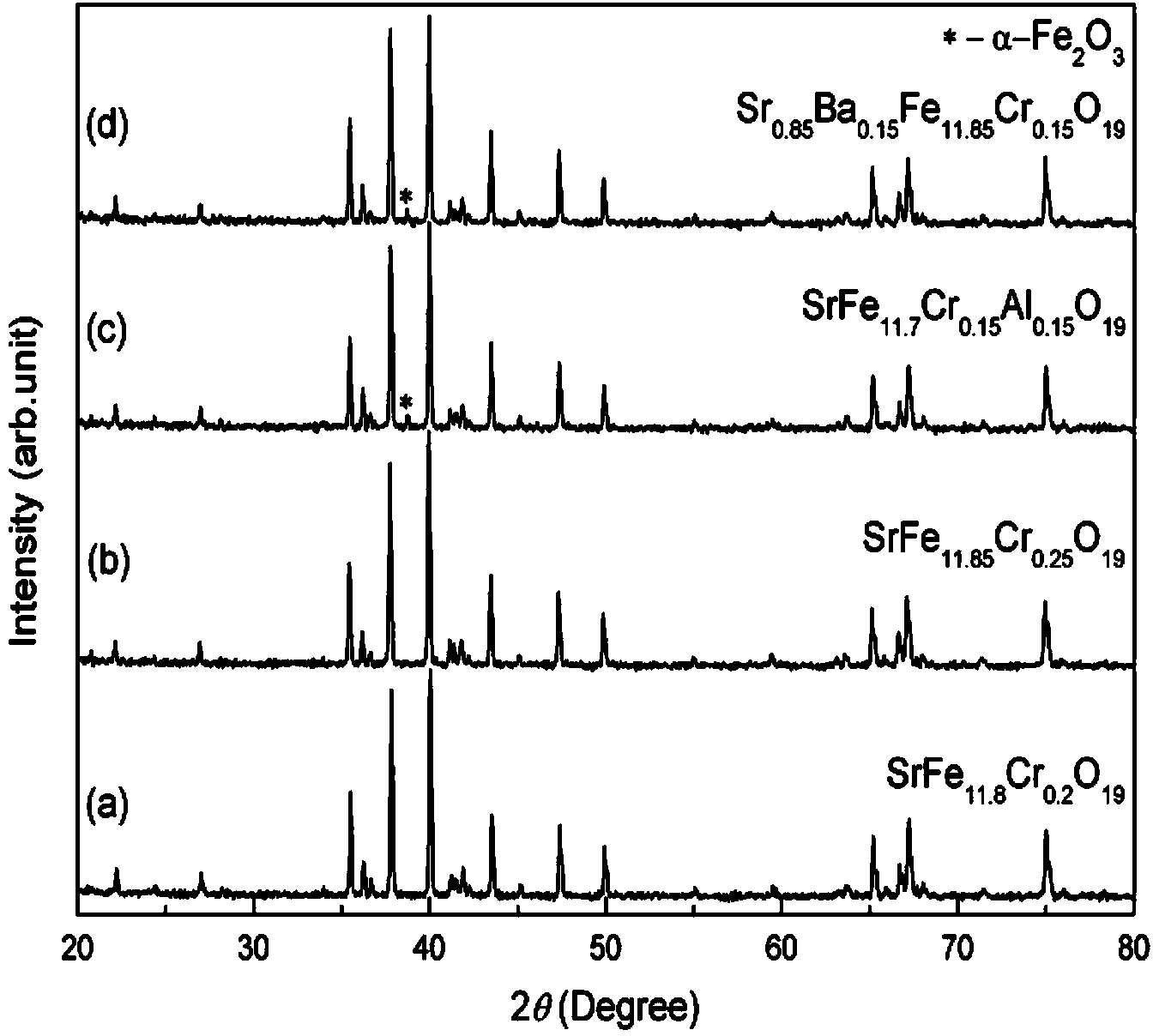

Embodiment 1

[0031] According to the chemical structure formula Sr 1-x Ba x o · n Fe (12-y) / n R y / n o 3 ( x =0.0, n =6.0, y =0.2, R is Cr) composition requirements, using industrially produced iron red (purity of 99.5%), strontium carbonate (purity of 99.05%) and industrially pure chromium trioxide as raw materials, one-time batching, and at the same time adding 0.2wt% CaCO 3 and 0.3wt% SiO 2 As a primary additive, mix with water and steel balls according to the weight ratio of material: water: ball = 1:1.5:15, and perform a ball mill for 2 hours to obtain a mixture with an average particle size of suspended particles of 1.25 μm.

[0032] After the mixed material is filtered, dried and granulated, it is pre-fired at 1290° C. and kept for 3 hours to prepare the M-type permanent magnet ferrite pre-fired material.

[0033] Then in the calcined powder obtained after crushing and sieving, add secondary additives, the addition of each component of the additive and the calcined powder ...

Embodiment 2

[0038] According to the chemical structure formula Sr 1-x Ba x o · n Fe (12-y) / n R y / n o 3 ( x =0.0, n =6.0, y =0.25, R is Cr) composition requirements, using industrially produced iron red (purity of 99.5%), strontium carbonate (purity of 99.05%) and industrially pure chromium trioxide as raw materials, a batching is carried out, and at the same time adding 0.2wt% CaCO 3 and 0.3wt% SiO 2 As a primary additive, mix with water and steel balls according to the weight ratio of material: water: ball = 1:1.5:15, and perform a ball mill for 2 hours to obtain a mixture with an average particle size of suspended particles of 1.24 μm.

[0039] After the mixed material is filtered, dried and granulated, it is pre-fired at 1290° C. and kept for 3 hours to prepare the M-type permanent magnet ferrite pre-fired material.

[0040] Then in the calcined powder obtained after crushing and sieving, add secondary additives, the addition of each component of the additive and the calcine...

Embodiment 3

[0045] According to the chemical structure formula Sr 1-x Ba x o · n Fe (12-y) / n R y / n o 3 ( x =0.0, n =6.0, y=0.3, R 1 Cr=0.15, R 2 According to the composition requirements of Al=0.15), industrially produced iron red (purity is 99.5%), strontium carbonate (purity is 99.05%), industrial pure chromium sesquioxide and aluminum sesquioxide are used as raw materials for a batching, and Add 0.2wt% CaCO at the same time 3 and 0.3wt% SiO 2 As a primary additive, mix with water and steel balls according to the weight ratio of material: water: ball = 1:1.5:15, and perform a ball mill for 2 hours to obtain a mixture with an average particle size of suspended particles of 1.25 μm.

[0046] After the mixed material is filtered, dried and granulated, it is pre-fired at 1290° C. and kept for 3 hours to prepare the M-type permanent magnet ferrite pre-fired material.

[0047] Then in the calcined powder obtained after crushing and sieving, add secondary additives, the addition of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com