Method for manufacturing NbTi-CuNi-Cu superconductive composite wire rod

A technology of nbti-cuni-cu and composite wire, which is applied in the field of superconducting wire preparation technology, can solve the problems of reducing the processing amount of passes, environmental pollution, increasing production cycle, etc., and is beneficial to hot extrusion and cold drawing processing , reduce costs, reduce the effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

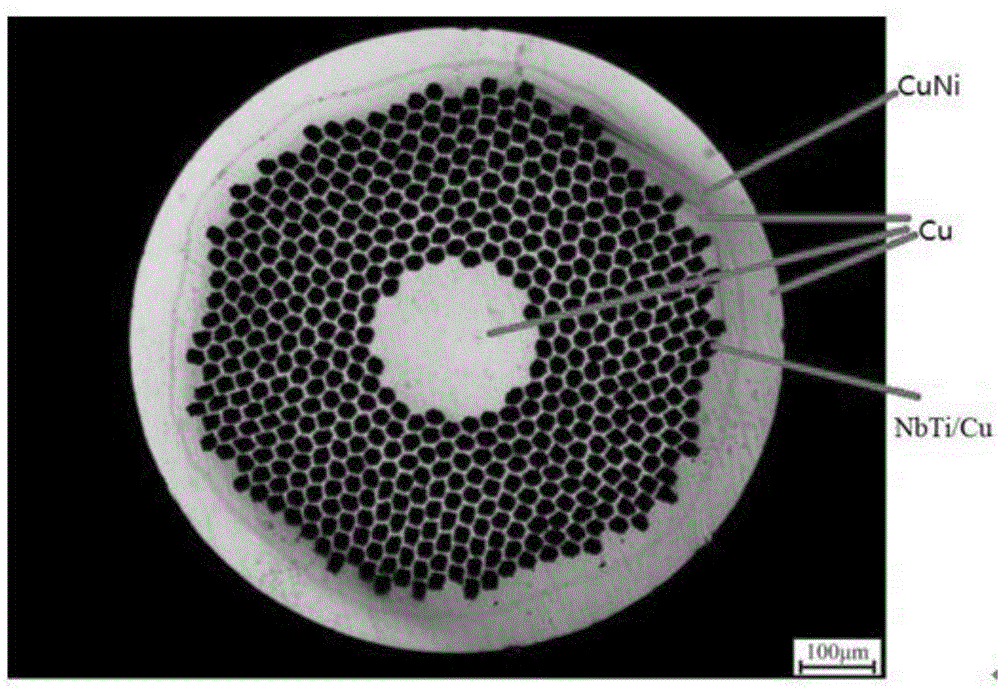

[0028] A kind of preparation method of NbTi-CuNi-Cu superconducting composite wire of the present invention specifically comprises the following steps:

[0029] step 1:

[0030] Take cleaned NbTi alloy rods and Cu tubes with a diameter of Φ20-250mm, the mass percentage content of Ti in the NbTi alloy rods is 45%-50%, and the wall thickness of the Cu tubes is 1 / 20-20% of the diameter of the NbTi alloy rods. 1 / 5, and then put the NbTi alloy rod into the Cu tube, you can add a cleaned Nb tube between the NbTi alloy rod and the Cu tube according to the performance requirements of the finished wire, and the thickness of the Nb tube is 1 of the diameter of the NbTi alloy rod. / 350-1 / 70, the NbTi / Cu single-core composite billet is obtained by hot extrusion or casing stretching. When hot extrusion is used, the two ends of the Cu tube need to be vacuum sealed with copper caps before processing;

[0031] Step 2:

[0032] The NbTi / Cu single-core composite rod obtained in step 1 is stre...

Embodiment 1

[0041]Adopt the Nb tube that the wall thickness is 2mm, the outer diameter is Φ151mm, and the Cu tube of the outer diameter Φ185mm, the inner diameter Φ156mm and the NbTi alloy rod (the mass percentage content of Ti 45wt%) of diameter Φ146mm, after cleaning, the NbTi alloy rod is packed into the Nb tube, and then put them into the Cu tube together. After sealing and welding at both ends, they are hot-extruded into a NbTi / Cu single-core composite billet; then the NbTi / Cu single-core composite billet is processed into a pair of Hexagonal rods with a side specification of 6.5mm, the pass processing rate is 10%; 528 hexagonal rods are cleaned and put into a Cu tube with an outer diameter of Φ182mm and an inner diameter of Φ170mm, and the Cu tube is then fitted with a wall thickness of 3mm and an outer diameter of Φ189mm CuNi alloy tube (the mass percentage content of Ni is 5wt%), and the gap part is filled with a small copper rod, and a Cu sheath with an outer diameter of Φ216mm an...

Embodiment 2

[0044] Three Nb coils with a thickness of 0.5mm are used to make Nb tubes with diameters of Φ171mm, Φ172mm, and Φ173mm, and they are packaged together from small to large, as well as Cu tubes with an outer diameter of Φ182mm and an inner diameter of Φ173mm and NbTi alloy rods of Φ169mm (Ti mass percentage Content 47wt%), after cleaning respectively, put the NbTi alloy rod into the coiled Nb tube, then put it into the Cu tube together, and heat-extrude it into a NbTi / Cu single-core composite billet after sealing and welding at both ends; then NbTi / Cu The Cu single-core composite bar blank is processed into a hexagonal bar with an opposite side specification of 15.2mm after multiple cold drawing and stretching, with a pass processing rate of 15%; 102 hexagonal bars are cleaned and loaded into Cu with an outer diameter of Φ183mm and an inner diameter of Φ175mm In the tube, the gap part is filled with a small copper rod, and the CuNi alloy tube with an outer diameter of Φ179.6mm an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com