Preparation method of novel compound wastewater treatment adsorbing agent

A sewage treatment and adsorbent technology, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, other chemical processes, etc., to achieve the effect of improving the decontamination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

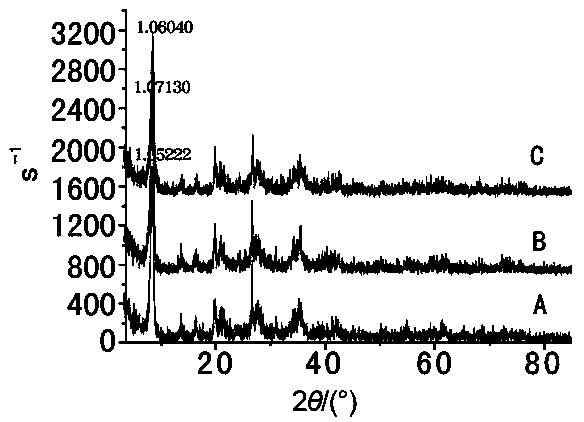

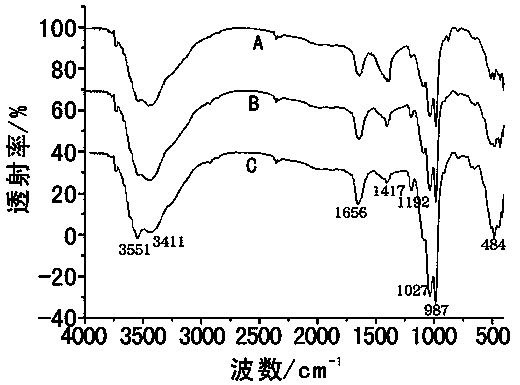

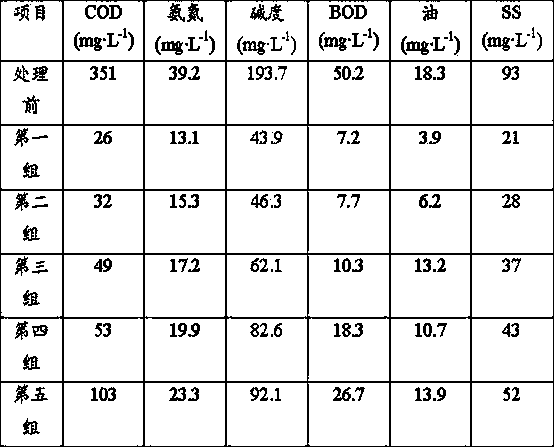

Image

Examples

preparation example Construction

[0034] The preparation method of nano manganese oxide is specifically:

[0035] At a temperature of 25°C, under the action of ultrasonic waves, slowly drop 40ml of potassium permanganate solution with a concentration of 0.1ml / L into the conical flask filled with 4ml of manganese acetate solution with a concentration of 1.5mol / L, drop Continue to sonicate for 5-10 min after adding. The brown-yellow manganese dioxide suspension obtained by the reaction was centrifuged at 8000 r / min at high speed, the supernatant was discarded, washed with deionized water until neutral, and 43.5 mL of deionized water was added to make MnO 2 Suspension, with a mass concentration of about 20g / L, stored at 0-4°C, for later use, the reaction formula is as follows:

[0036] 2KMnO 4 + 3Mn (Ac) 2 + 2H 2 O→ 5MnO 2 + 2KAc +4HAc.

[0037] Potassium ferrate can sterilize and sterilize, oxidize and remove reducing substances such as ammonia nitrogen, sulfur substances, phenols, etc. in water, and wil...

Embodiment 1

[0051] Embodiment 1 Preparation of dendritic quaternary ammonium salt tetrameric surfactant

[0052] Add 40ml of absolute ethanol and 4.5g of ethylenediamine to a 250ml three-neck flask equipped with a condenser, and magnetically stir at room temperature, add 34.7g of epichlorohydrin at 10 drops / min, and reflux for 4 hours after the addition is complete. Obtain tetrameric surfactant intermediate after decompression distillation, be light yellow translucent viscous liquid, get this intermediate 20g, be the dehydrated alcohol and deionized water mixed solution 40ml of 1:1 with volume ratio as solvent, then Add 7.9g of N,N-dimethyldodecyl tertiary amine dropwise, heat up to 80°C, react for 1h, distill under reduced pressure, recrystallize, and dry in vacuo to obtain a white powdery solid that is dendritic quaternary ammonium salt tetrameric surface active agent.

Embodiment 2

[0053] Attapulgite clay modified by embodiment 2 dendritic quaternary ammonium salt tetrameric surfactant

[0054] Add 100g of attapulgite clay to deionized water, stir for 1 hour, then heat up to 40°C, add 15g of the dendritic quaternary ammonium salt tetrameric surfactant prepared in Example 1, stir for 7 hours, filter, wash, dry and pulverize , to obtain modified attapulgite clay powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com