Preparation methods of antimony trioxide and antimony trioxide composite material and applications of antimony trioxide and antimony trioxide composite material in sodium-ion batteries

An antimony trioxide and composite material technology, applied in battery electrodes, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of capacity decay, cracking and pulverization of negative electrode materials, and falling off, and achieve high specific capacity, ease volume expansion, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

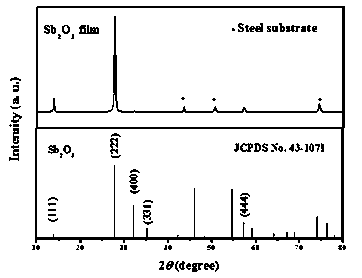

[0028] In this example, electrostatic spray deposition is used to prepare antimony trioxide sodium ion battery negative electrode material, and the specific steps are:

[0029] Dissolve antimony acetate in a mixed solvent of ethanol / ethylene glycol (4:1 by volume) to form a precursor solution with a concentration of 0.01 mol / L, and flow the precursor solution to the spray needle at a constant speed of 3ml / h to adjust the spray The distance from the needle to the substrate is 4 cm. Under the action of an electrostatic field of 7 kV, the precursor solution forms a stable and uniform aerosol spray, which is deposited on a stainless steel substrate with a heating temperature of 160 °C. The deposition time is controlled to be 240 min, and three antimony oxide film.

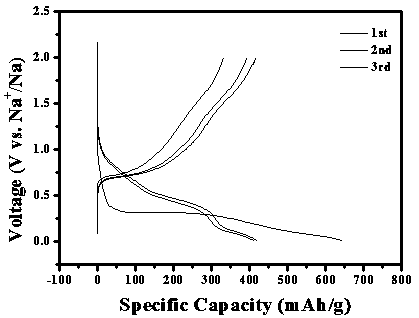

[0030] The above-mentioned antimony trioxide film, that is, the negative electrode material of the sodium ion battery, is prepared into a sodium ion battery. The antimony trioxide thin film can be directly used as a n...

Embodiment 2

[0032] In this embodiment, a ball milling method is used to prepare antimony trioxide / carbon composite material, and the specific steps are:

[0033] The antimony trioxide powder and Super P (mass ratio: 7:3) were ball milled and mixed in an argon-filled ball mill tank at 500 rpm for 6 hours to obtain a carbon-coated antimony trioxide / carbon composite material, in which three The mass fraction of antimony oxide is 70%.

[0034]The above composite materials were prepared into sodium-ion batteries. The specific steps are: mix the prepared antimony trioxide powder with acetylene black and binder PVDF (polyvinylidene fluoride) according to the weight ratio of 80:10:10, and add an appropriate amount of NMP (N-methylpyrrolidone) solution Ultrasonic dispersion, stirring evenly to form a slurry coated on the copper foil, dried and cut into Φ = 15mm pole piece, dried at 120 ℃ under vacuum for 10 hours, randomly transferred into the glove box for later use. The test method of the asse...

Embodiment 3

[0036] In this embodiment, a ball milling method is used to prepare antimony trioxide / iron oxide composite material, and the specific steps are:

[0037] Mix antimony trioxide powder with iron nitrate (mass ratio 1:5) by ball milling at 500 rpm for 10 hours, and heat-treat the mixed powder at 300°C for 5 hours to obtain antimony trioxide / iron oxide composite material, in which The mass fraction of diantimony is about 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com