Method for preparing solvent-free waterborne polyurethane resin for synthesizing leather bonding layer

A water-based polyurethane, solvent-free technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of low production costs, improve toughness, increase bonding strength, and increase elongation at break rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

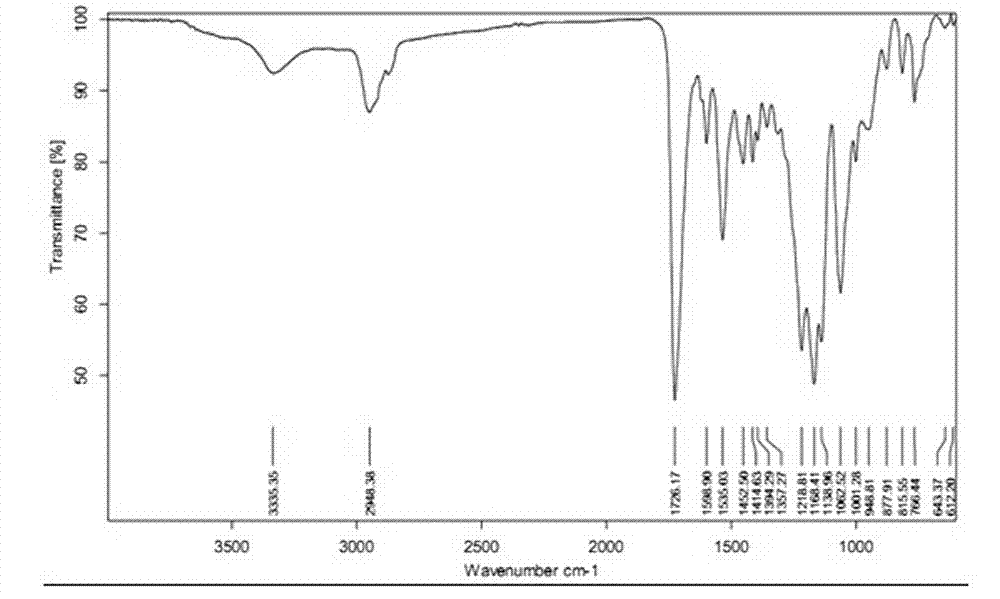

Image

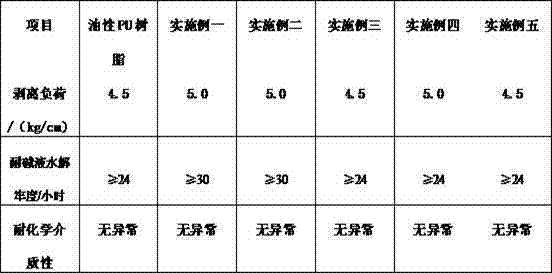

Examples

Embodiment 1

[0027] The first step, add the propylene oxide polyether polyol of 35g polycaprolactone polyol and 50g in the four-hole bottle that is equipped with thermometer, reflux condenser and constant speed stirrer, the molecular weight of polycaprolactone polyol is 2000, The molecular weight of propylene oxide polyether polyol is 1000, vacuum dehydration at 110℃~120℃ for 2 hours, then cool down to 50℃, then add 30g of toluene diisocyanate, 3.5g of neopentyl glycol and 0.1g of organic bismuth Add the catalyst into the reactor and gradually raise the temperature to 80°C for 2 hours of polymerization, then add 5.3g of dimethylolbutyric acid to continue the constant temperature reaction for 2.5 hours, take samples, and use the di-n-butylamine method to measure its NCO value. After the index is qualified, cool down to 70 Below ℃, add 3.9g triethylamine to neutralize, then add 1.2g acetonimine to obtain waterborne polyurethane resin prepolymer;

[0028] In the second step, add 200g of deion...

Embodiment 2

[0031] The first step, add the propylene oxide polyether polyol of 35g polycarbonate polyol and the propylene oxide polyether polyol of 50g in the four-neck flask that is equipped with thermometer, reflux condenser and constant speed stirrer, the molecular weight of polycarbonate polyol is 2000, epoxy The molecular weight of propane polyether polyol is 1000, and it is dehydrated under vacuum for 2 hours at a temperature of 110°C to 120°C, then cooled to 50°C, and then 30g of toluene diisocyanate, 3.1g of neopentyl glycol and 0.1g of bismuth-zinc alloy catalyst Add it into the reactor and gradually raise the temperature to 80°C for 2 hours of polymerization, then add 5.3g of dimethylol butyric acid to continue the heat preservation reaction for 2.5 hours, take samples, use the di-n-butylamine method to measure its NCO value, and cool down to 70°C after the index is qualified Next, add 3.9g triethylamine to neutralize, then add 1.2g acetonimine to obtain the waterborne polyuretha...

Embodiment 3

[0035]The first step, add the polytetrahydrofuran ether polyol of 42g polycaprolactone polyol and 44g in the four-neck flask that is equipped with thermometer, reflux condenser and constant speed stirrer, the molecular weight of polycaprolactone polyol is 2000, polytetrahydrofuran The molecular weight of the ether polyol is 1000, vacuum dehydration at a temperature of 110°C to 120°C for 2 hours, and then lower the temperature to 60°C, then add 27.5g of hexamethylene diisocyanate, 3.1g of neopentyl glycol and 0.3g of organic bismuth Add the catalyst into the reactor and gradually raise the temperature to 80°C for 2 hours of polymerization, then add 5.3g of dimethylolbutyric acid to continue the heat preservation reaction for 2.5 hours, take samples, and use the di-n-butylamine method to measure the NCO value. After the index is qualified, the temperature is lowered to 70 Below ℃, add 3.9g triethylamine to neutralize, then add 1.8g N-phenylacetonimine to obtain waterborne polyure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com