Flocculant for purifying landscape water and preparation method of flocculant

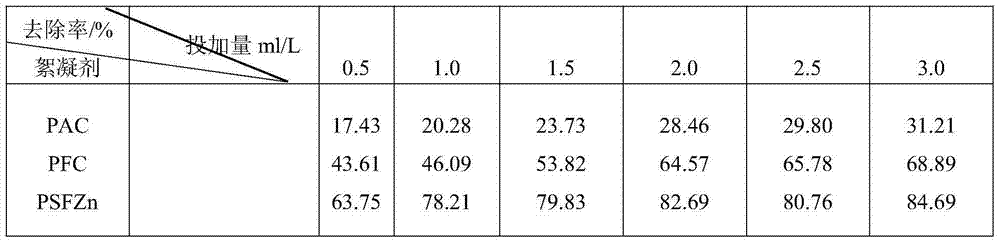

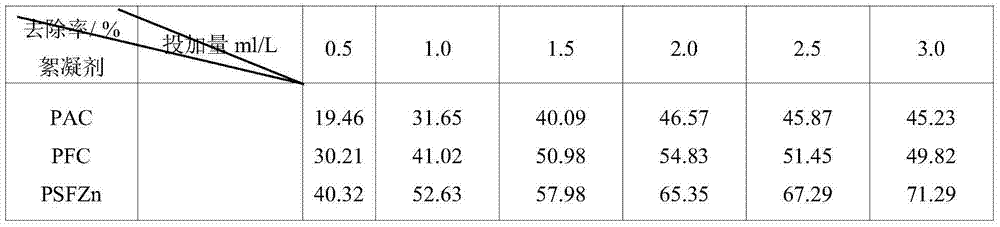

A flocculant and landscape technology, applied in the field of new flocculants, can solve the problems of poor water quality adaptability, difficulty in large-scale production, large quantities, etc., and achieve the effects of not harsh water conditions, high efficiency of turbidity and algae removal, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The mass percent of each raw material in the PSFZn in this example is: industrial water glass 30%, ferric chloride 1%, zinc sulfate 2%, dilute hydrochloric acid is 10%, sodium bicarbonate 10%, surplus is deionized water.

[0030] Concrete preparation method is as follows:

[0031] (1) After diluting the water glass with deionized water, slowly add it to part (half) of dilute hydrochloric acid under magnetic stirring at a speed of 500r / min, and adjust the pH value to 4 with the remaining (half) hydrochloric acid, at 20 The polysilicic acid solution was obtained after activation at ℃ for 30 minutes.

[0032] (2) Put FeCl at a speed of 300r / min 3 , ZnSO 4 Added to the polysilicic acid solution mentioned above one after another, after stirring for 25min. Sodium bicarbonate was added, and stirring was continued for 10 min to obtain PSFZn.

Embodiment 2

[0038] In the PSFZn in this example, each raw material is by mass percentage: industrial water glass 25%, ferric chloride 4%, zinc sulfate 4%, dilute hydrochloric acid is 20%, sodium bicarbonate 10%, surplus is deionized water.

[0039] Concrete preparation method is as follows:

[0040] (1) After diluting the water glass with deionized water, slowly add it to some dilute hydrochloric acid under magnetic stirring at a speed of 400r / min, adjust the pH value to 5 with the remaining hydrochloric acid, and activate at 40°C for 20 minutes After that, polysilicic acid solution is obtained.

[0041] (2) Put FeCl at a speed of 300r / min 3 , ZnSO 4 Added to the polysilicic acid solution mentioned above one after another, after stirring for 45min. Sodium bicarbonate was added, and stirring was continued for 15 min to obtain PSFZn.

Embodiment 3

[0047] The raw materials in PSFZn in this example are by mass percentage: industrial water glass 21%, ferric chloride 8%, zinc sulfate 4%, dilute hydrochloric acid is 20%, sodium bicarbonate 5%, surplus is deionized water.

[0048] Concrete preparation method is as follows:

[0049] (1) After diluting the water glass with deionized water, slowly add it to part (such as 2 / 3) of dilute hydrochloric acid under magnetic stirring at a speed of 600r / min, and then use the remaining (such as 1 / 3) The pH value was adjusted to 6 with hydrochloric acid, and the polysilicic acid solution was obtained after activation at 28° C. for 30 minutes.

[0050] (2) Put FeCl at a speed of 400r / min 3 , ZnSO 4 Add it to the polysilicic acid solution mentioned above, and stir for 60 minutes. Sodium bicarbonate was added, and stirring was continued for 20 min to obtain PSFZn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com