Method for degrading methyl orange by use of perovskite/polysaccharide composite photocatalyst

A composite photocatalytic and perovskite technology, applied in the field of photocatalytic degradation of methyl orange, perovskite/polysaccharide composite photocatalytic degradation of methyl orange, to improve photocatalytic degradation ability, high catalytic degradation effect, and conducive to recycling The effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

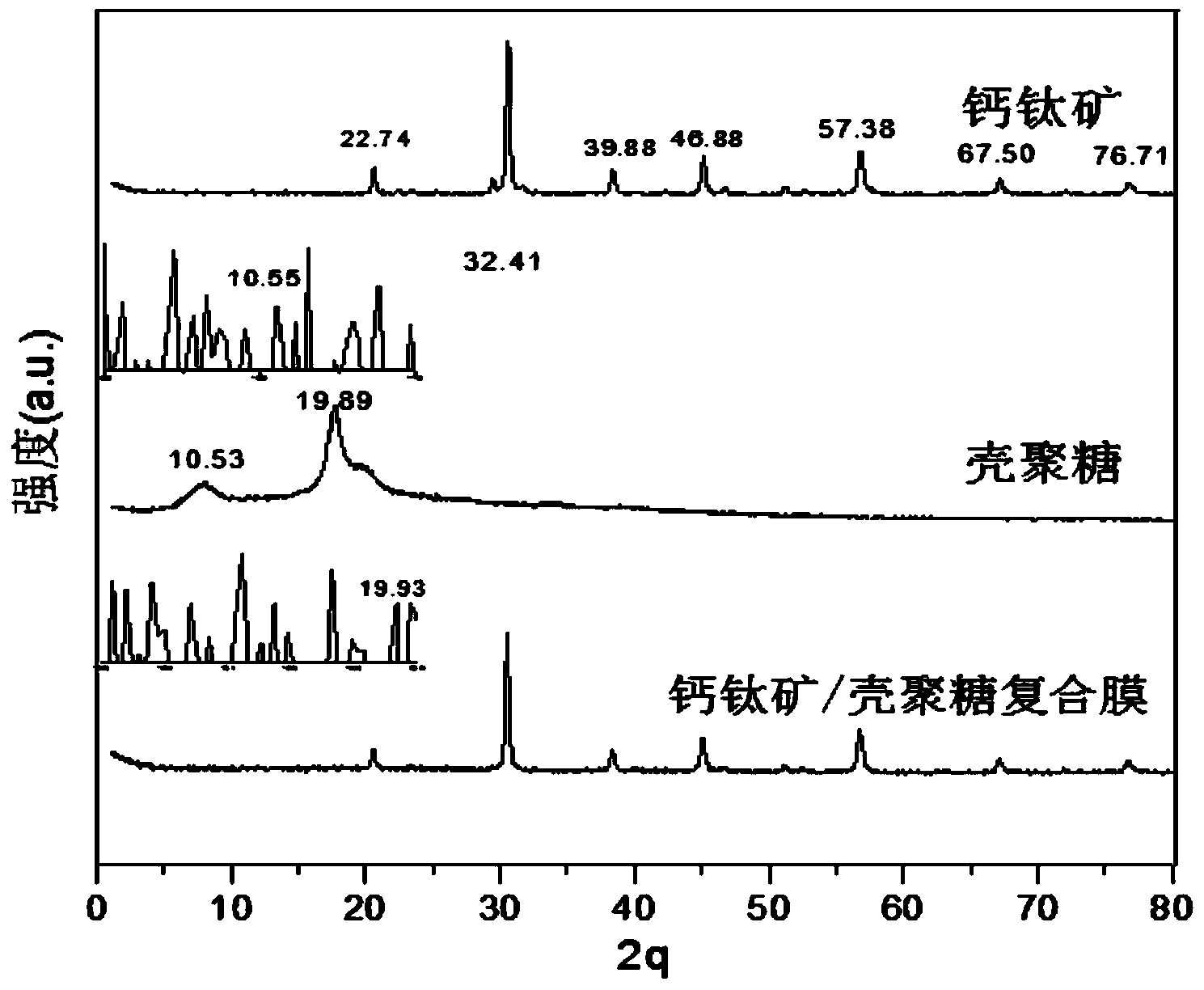

[0036] (1) Preparation of perovskite oxide by sol-gel method: 43.3g La(NO 3 ) 3 .6H 2 O,30.78g Fe(NO 3 ) 2 .9H 2 O and 2.42g Cu(NO 3 ) 2 .3H 2 O was dissolved in 100mL of distilled water, 54.6g of citric acid and 18.2mL of ethylene glycol were added, then dried at 110°C to an expanded state, then calcined in a muffle furnace at 700°C for 10h, cooled and ground to obtain perovskite Mine LaFe 0.9 Cu 0.1 o 3 Precursor. figure 2 Perovskite LaFe prepared in 0.9 Cu 0.1 o 3 XRD patterns of precursors and LaFe in literature reports 0.9 Cu 0.1 o 3 The XRD diagram of (Junhua Zhang, Haibo Deng, Lu Lin. Wet Aerobic Oxidation of Lignin into Aromatic Aldehydes Catalysed by a Perovskite‐type Oxide: LaFe 1‐x Cu x o 3 , Molecules2009,14,2747‐2757; the perovskite is used to catalyze lignin) consistent, proving that the perovskite prepared by this method is LaFe 0.9 Cu 0.1 o 3 .

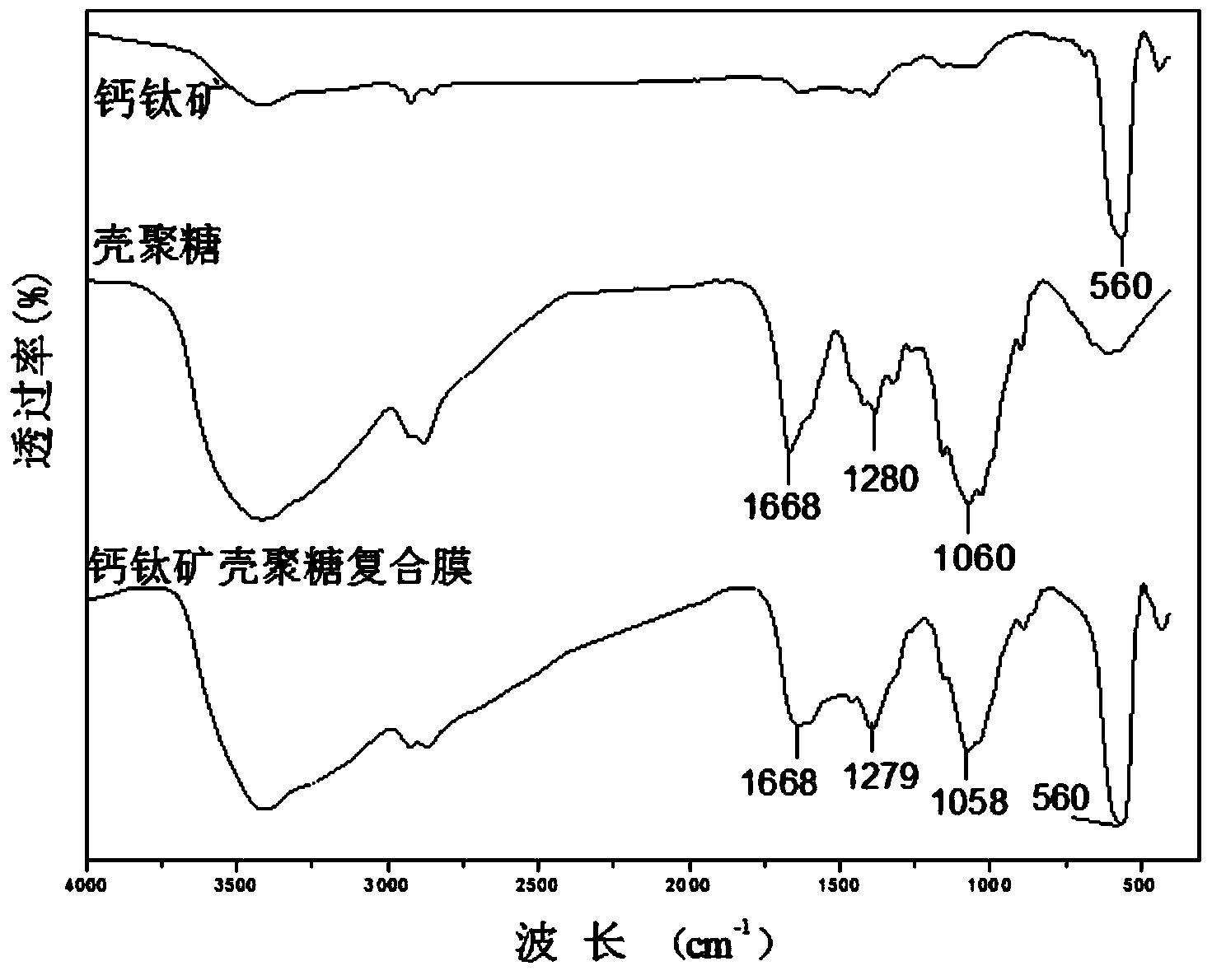

[0037] (2) Perovskite / chitosan composite photocatalytic material: Add 1g chitosan to 40mL ac...

Embodiment 2

[0047] (1) Preparation of perovskite oxide by sol-gel method: 43.3g La(NO 3 ) 3 .6H 2 O,27.36g Fe(NO 3 ) 2 .9H 2 O and 4.84g Cu(NO 3 ) 2 .3H 2 O was dissolved in 100mL of distilled water, 63g of citric acid and 21.6mL of ethylene glycol were added, then dried at 120°C into an expanded state, then calcined in a muffle furnace at 800°C for 8 hours, cooled and ground to obtain perovskite LaFe 0.8 Cu 0.2 o 3 Precursor.

[0048] (2) Perovskite / chitosan composite photocatalytic material: add 1g chitosan to 50mL acetic acid solution with a mass concentration of 2.5%, stir to dissolve, then add 1g perovskite powder, ultrasonic treatment for 2h, ultrasonic frequency It is 35KHz and dried at 60°C to form a film. Add the prepared membrane to 50mL of 0.25mol / L sodium hydroxide solution for coagulation, and then immerse the membrane in 100mL of 0.25% glutaraldehyde by volume for 60min. Finally, wash with ethanol and water respectively, and dry at 50°C for 24h.

[0049] (3) Pe...

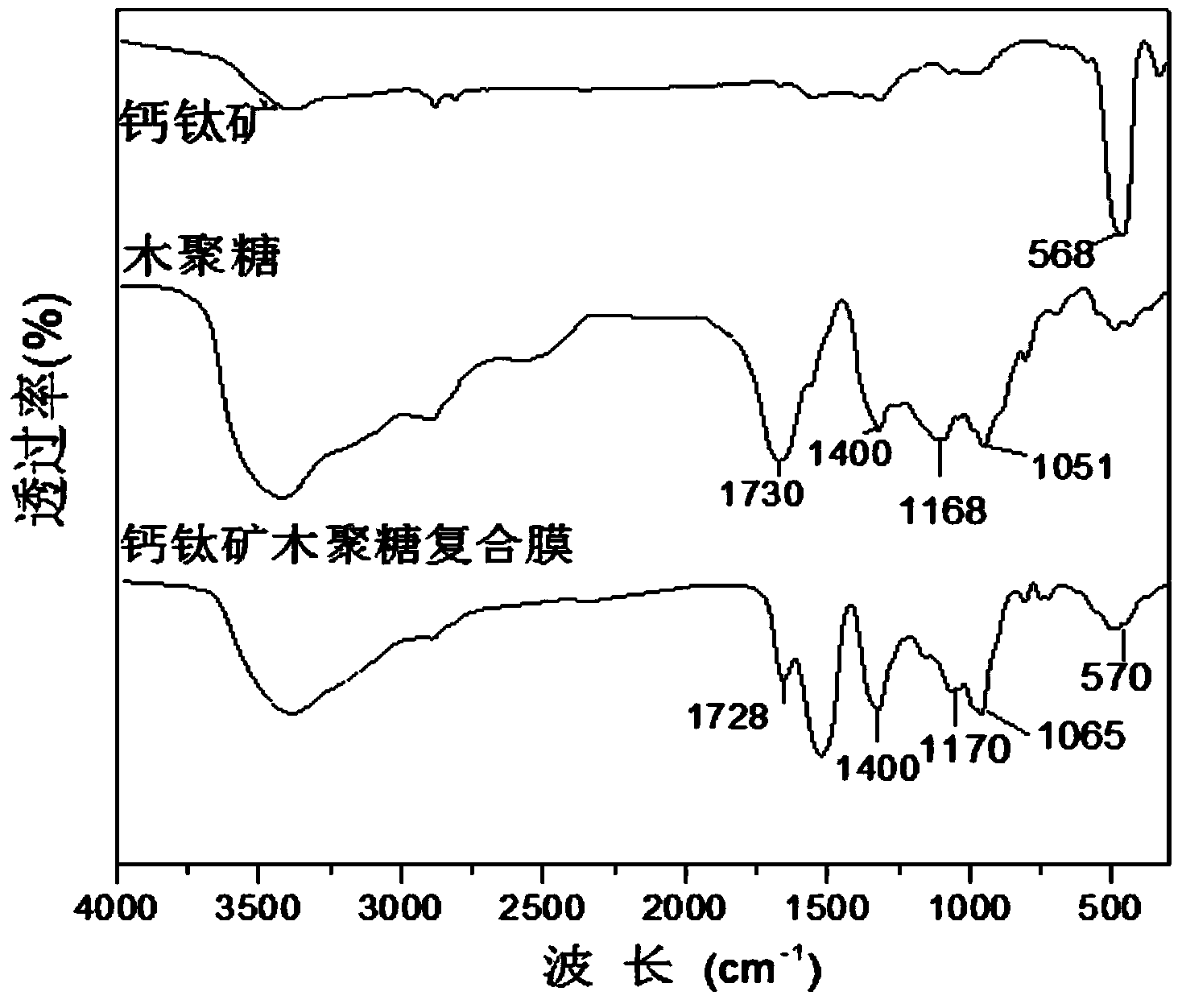

Embodiment 3

[0053] (1) Preparation of perovskite oxide by sol-gel method: 43.3g La(NO 3 ) 3 .6H 2 O,17.1g Fe(NO 3 ) 2 .9H 2 O and 12.1g Cu(NO 3 )2 .3H 2 O was dissolved in 100mL of distilled water, 71.4g of citric acid and 26.78mL of ethylene glycol were added, then dried at 130°C into an expanded state, then calcined in a muffle furnace at 900°C for 6h, cooled and ground to obtain perovskite Mine LaFe 0.5 Cu 0.5 O3 precursor. It is calculated based on the amount of substances added by various elements during the preparation process.

[0054] (2) Perovskite / chitosan composite photocatalytic material: add 1g chitosan to 60mL 3% acetic acid solution, stir to dissolve, then add 2g perovskite powder, ultrasonic treatment for 3h, ultrasonic frequency is 40KHz, in Dry at 70°C to form a film. Add the prepared membrane to 55mL of 0.3mol / L sodium hydroxide solution for coagulation, and then immerse the membrane in 110mL of 0.25% glutaraldehyde by volume for 90min. Finally, wash with et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com