One-time moistening and humidifying device for threshing and redrying tobacco leaves

A technology of threshing, re-curing and humidifying device, which is applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of poor hygroscopicity, poor moisturizing effect and decline of tobacco leaves, and achieves the effect of normal control and stable operation of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

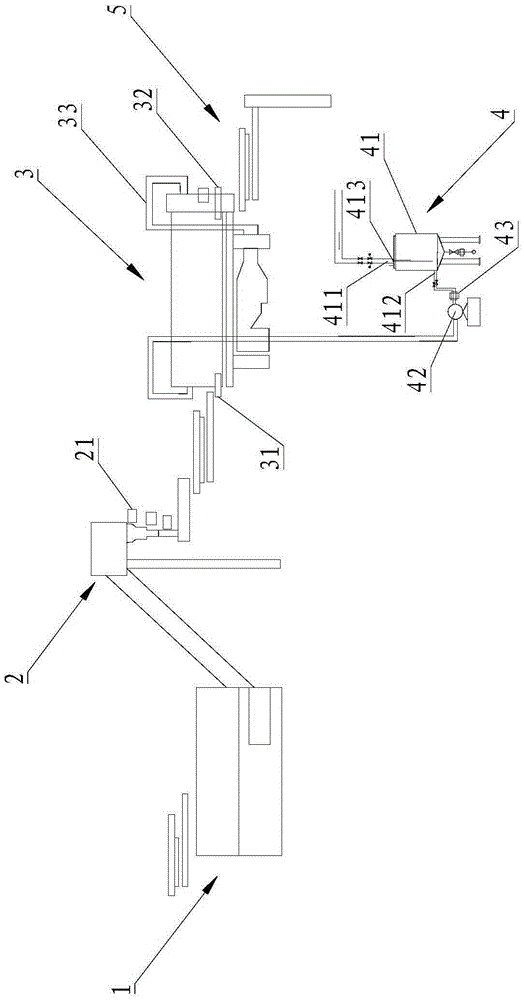

[0022] see figure 1 , the primary moistening and humidifying device for beating and redrying tobacco leaves of the present invention comprises a feeding conveyor belt 1, a metering device 2, a leaf moistening machine 3, a humidifying water stabilizing device 4 and a discharge conveyor belt 5; the feeding conveyor belt 1 is connected to the feed port 31 of the leaf conditioner 3 through the metering device 2, the discharge conveyor belt 5 is connected to the discharge port 32 of the leaf conditioner 3, and the nozzle of the leaf conditioner 3 is provided with an electromagnetic Valve, the metering device 2 is provided with a sensor 21, the sensor 21 is electrically connected to the controller of the solenoid valve and transmits the sensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com