Preparation method of n-channel silicon carbide insulated gate bipolar transistor

A technology of bipolar transistors and silicon carbide, which is applied in the field of microelectronics, can solve the problems of high energy consumption in the epitaxial process, high manufacturing cost, and large on-resistance, so as to save manufacturing cost and time, save resources and energy, and reduce The effect of preparation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

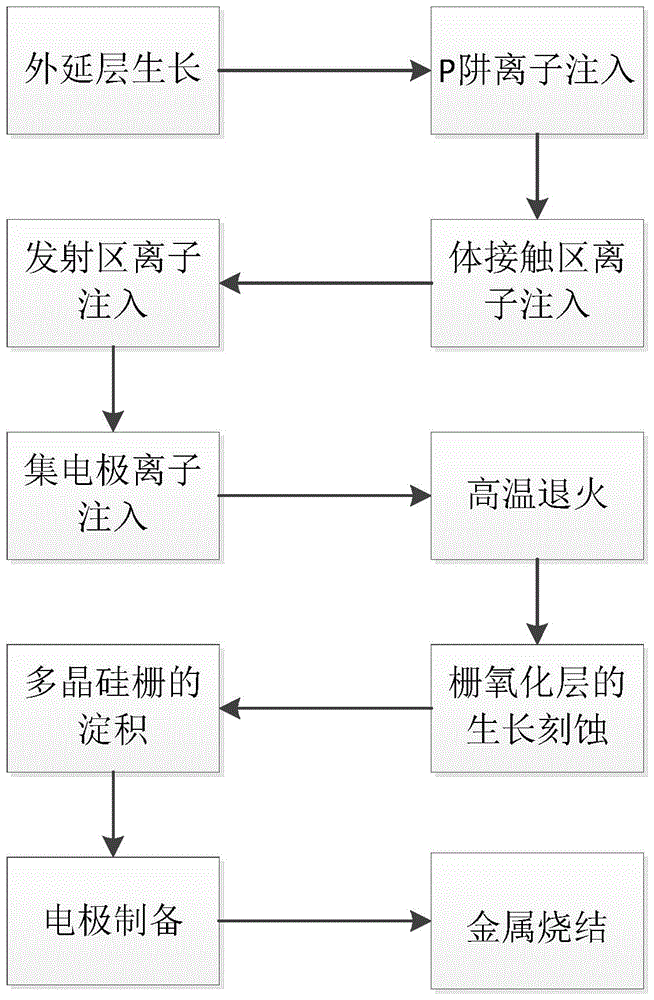

Method used

Image

Examples

Embodiment 1

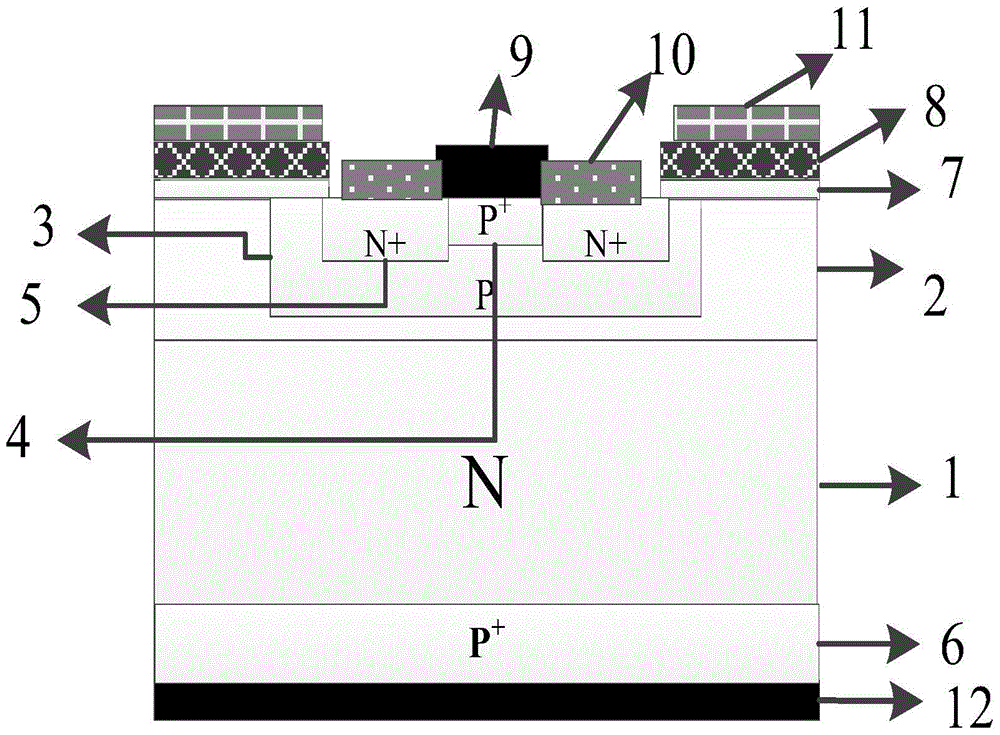

[0031] Example 1: Dislocations in the base plane are 10 4 / cm -3 , the substrate concentration is 2×10 14 cm -3 N-channel silicon carbide insulated gate bipolar transistors were prepared on the micropipe-free N-type SiC substrate.

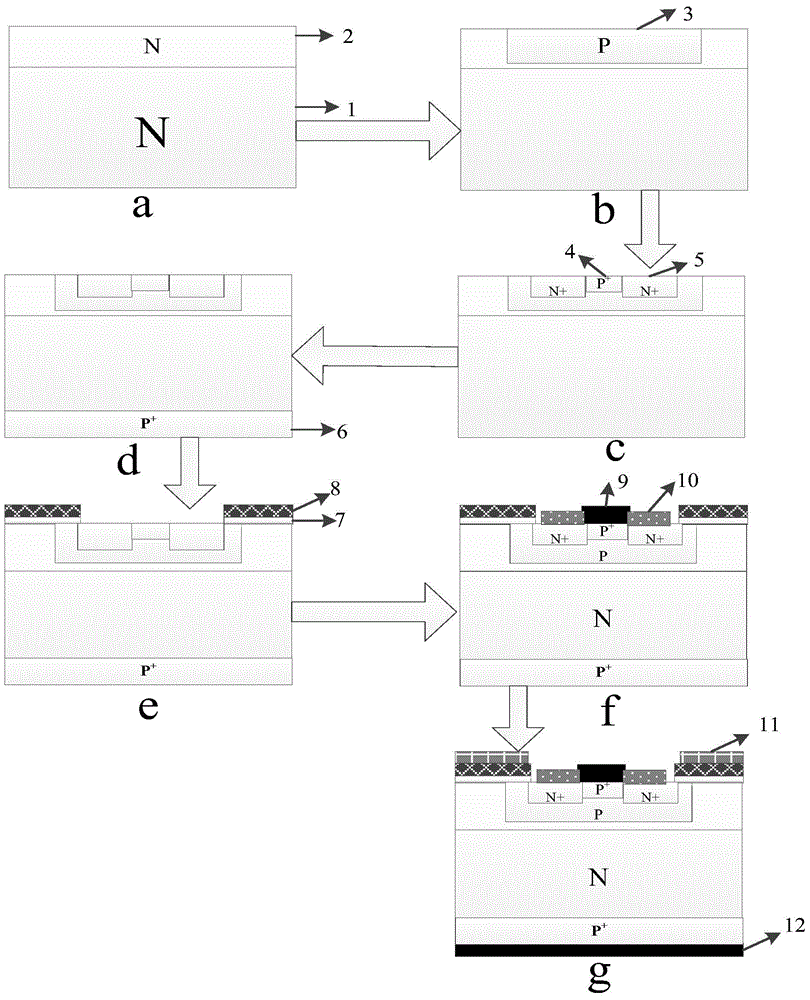

[0032] Step 1: grow epitaxial layer.

[0033] First perform RCA standard cleaning on the N-type silicon carbide substrate 1, and then epitaxially grow on the entire substrate with a thickness of 0.8 μm and a nitrogen ion doping concentration of 2×10 15 cm -3 N-type epitaxial layer 2, such as image 3 a, The epitaxy process conditions are: temperature 1600°C, pressure 100mbar, silane and propane as reaction gas, pure hydrogen as carrier gas, and liquid nitrogen as dopant source.

[0034] Step 2: P well implantation.

[0035] (2.1) Deposit Al with a thickness of 1.5 μm on the entire silicon carbide epitaxial layer by low-pressure chemical vapor deposition as a barrier layer for P-well ion implantation, and then apply glue and photoetch the P-w...

Embodiment 2

[0058] Example 2: Dislocations in the base plane are 10 4 / cm -3 , the substrate concentration is 3×10 14 cm -3 N-channel silicon carbide insulated gate bipolar transistors were prepared on the micropipe-free N-type SiC substrate.

[0059] refer to figure 1 and figure 2 , the implementation steps of this embodiment are as follows:

[0060] Step 1: RCA standard cleaning is performed on the N-type SiC substrate 1 first, and the epitaxial growth thickness on the entire substrate is 1 μm, and the nitrogen ion doping concentration is 5×10 15 cm -3 N-type epitaxial layer 2, such as image 3 a. The process conditions are as follows: temperature is 1600°C, pressure is 100mbar, silane and propane are used as reaction gas, pure hydrogen is used as carrier gas, and liquid nitrogen is used as dopant source.

[0061] The second step: P well injection.

[0062] The specific implementation of this step is the same as step 2 of embodiment 1.

[0063] The third step: apply glue on t...

Embodiment 3

[0073] Dislocations in the basal plane are 10 4 / cm -3 , the substrate concentration is 5×10 14 cm -3 N-channel silicon carbide insulated gate bipolar transistors were prepared on the micropipe-free N-type SiC substrate.

[0074] refer to figure 1 and figure 2 , the implementation steps of this embodiment are as follows:

[0075] Step A: epitaxial layer growth.

[0076] First perform RCA standard cleaning on the N-type silicon carbide substrate 1, and then epitaxially grow the entire substrate with a thickness of 1.4 μm and a nitrogen ion doping concentration of 7×10 15 cm -3 N-type epitaxial layer 2, such as image 3 a, The epitaxy process conditions are: temperature 1600°C, pressure 100mbar, silane and propane as reaction gas, pure hydrogen as carrier gas, and liquid nitrogen as dopant source.

[0077] Step B: P-well implantation.

[0078] The specific implementation of this step is the same as step 2 of embodiment 1.

[0079] Step C: P + Body contact area injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com