Method for preparing prodigiosin fermentation liquor

A technology for producing prodigiosin and prodigiosin, which is applied in the field of fermented liquid for producing prodigiosin, can solve problems such as backward technology, low output, and low oil utilization efficiency, and achieve broad market prospects and ecological protection The effect of improving the environment and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

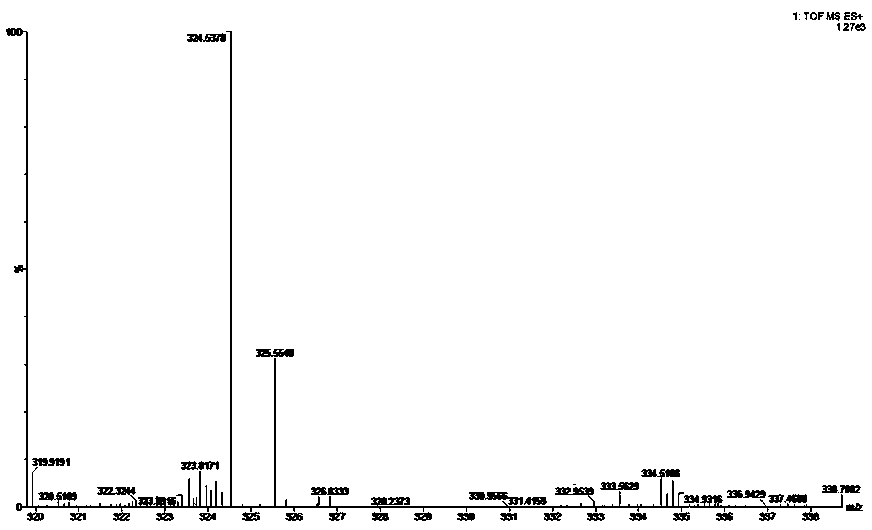

Image

Examples

Embodiment 1

[0022] Preparation of woody vegetable oil: Take the mature seeds of Pistacia chinensis, dry them until the moisture content is 5%, and grind them mechanically to 15 mesh; During the process of pressing, crude oil is obtained; the crude oil is hydrated and degummed, acid neutralized, deodorized, and decolorized to obtain the finished pistachio oil. The fatty acids contained in Pistacia oil mainly include palmitic acid, oleic acid, linoleic acid, palmitoleic acid, stearic acid, arachidonic acid, and linolenic acid, of which the sum of oleic acid, linoleic acid, and palmitic acid accounts for About 95% of the total. The oil content of Pistacia chinensis is 56.5%, the oil yield of seeds is 20%-30%, and the oil content of husk is 3.28%. It is a non-drying oil with a light yellow-green color and a bitter taste.

[0023] (1) Preparation of seed medium: distilled water as solvent, ingredients and mass ratio: 1% woody vegetable oil, 1.5% yeast peptone, 1.5% ammonium sulfate, 0.1% pota...

Embodiment 2

[0028] Preparation of woody vegetable oil: Take the mature seeds of the glabra tree, dry them to a moisture content of 8%, and grind them mechanically to 10 meshes; Press at ℃ to obtain crude oil; the crude oil is hydrated and degummed, neutralized acid, deodorized, and decolorized to obtain eucalyptus seed oil. The fatty acid composition of eucalyptus glabra seed oil is mainly linoleic acid and Oleic acid, the described eucalyptus is a kind of woody oil plant, and the pulp and seed kernel all contain more oil.

[0029] (1) Preparation of seed medium: use distilled water as solvent; ingredients and their mass ratios are: woody vegetable oil 2%, yeast peptone 3%, ammonium sulfate 1%, potassium dihydrogen phosphate 0.1%, sodium nitrate 0.2%, Magnesium sulfate heptahydrate 0.05%; pH value is 7.5; prepared to obtain seed culture medium.

[0030] (2) Preparation of fermentation medium: use distilled water as solvent; ingredients and their mass ratios are: woody vegetable oil 12%, ...

Embodiment 3

[0034] Preparation of woody vegetable oil: Take the mature seeds of tung tree, dry them until the water content is 5%, and grind them mechanically to 10 meshes; When the oil is pressed, crude oil is obtained; the crude oil is hydrated and degummed, acid neutralized, deodorized, and decolorized to obtain tung oil. The refractive index of tung oil is 1.5206, the acidification value is 5.1 mg / g, the iodization value is 165 mg / g, the saponification value is 190 mg / g, the transparency is transparent, the color value is 0.1, the smell has no peculiar smell, and the density is 0.9376 g / mL, the thermal polymerization time is 446 seconds, and contains β-tung acid. The fruit of the tung tree contains about 10 kernels, and the oil content of the kernels is about 62.89%.

[0035] (1) Preparation of seed medium: use distilled water as solvent; ingredients and their mass ratios are: 1% woody vegetable oil, 1% yeast peptone, 1% ammonium sulfate, 0.15% potassium dihydrogen phosphate, 0.2% sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saponification value | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com