Dual-function film coated glass capable of realizing anti-dazzle performance and visible light antireflection and preparation method of glass

A technology of coated glass and anti-reflection film, applied in chemical instruments and methods, glass/slag layered products, layered products, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

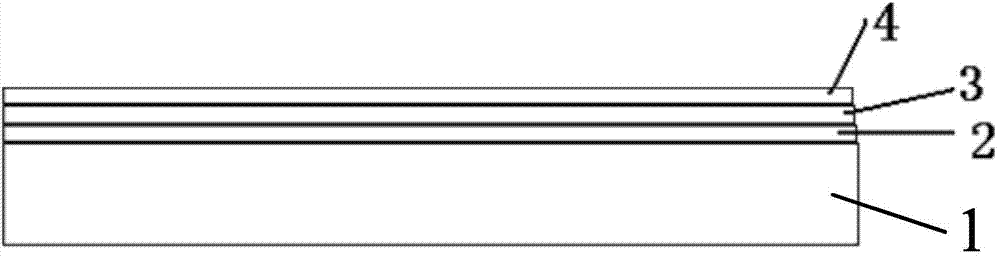

[0030] The preparation method of the anti-glare and visible light anti-reflection dual-function coated glass of the present invention comprises the following steps:

[0031] 1. Plating isolation layer: In the vacuum box, the flow ratio of oxygen and argon is 5:100, and the sputtering pressure is 2.5×10 -1 Pa, pure silicon is used as the target material, and the thickness of the deposited silicon oxide film is 5nm.

[0032] 2. Plating concave-convex nano-micro composite pore structure suede film layer: in the vacuum box, argon is used as the working gas, and the sputtering pressure is 2.5×10 -1 Pa, zinc oxide is used as the target material, and the deposited film thickness is 60nm.

[0033] 3. In the atmospheric environment, corrode the plated glass with hydrochloric acid with a weight concentration of 3% for 10 seconds, and the zinc oxide film layer forms a textured surface with a concave-convex nano-micro composite pore structure, and the pore size is 10-500nm; the hydrochlo...

Embodiment 2

[0037] The preparation method of the anti-glare and visible light anti-reflection dual-function coated glass of the present invention comprises the following steps:

[0038] 1. Plating isolation layer: In the vacuum box, the flow ratio of oxygen and argon is 12:100, and the sputtering pressure is 3.0×10 -1 Pa, silicon aluminum is used as the target material, and the thickness of the deposited silicon oxide film is 10nm.

[0039] 2. Plating concave-convex nano-micro composite velvet film layer: in the vacuum box, argon is used as the working gas, and the sputtering pressure is 3.0×10 -1 Pa, aluminum-doped zinc oxide is used as the target material, and the thickness of the deposited film layer is 80nm.

[0040] 3. In the atmospheric environment, corrode the plated glass with hydrochloric acid with a weight concentration of 5% for 20 seconds, and the plated doped zinc oxide film layer forms a concave-convex nano-micro composite pore structure suede, and the pore size is 10-500nm; ...

Embodiment 3

[0044] The preparation method of the anti-glare and visible light anti-reflection dual-function coated glass of the present invention comprises the following steps:

[0045] 1. Plating isolation layer: In the vacuum box, the flow ratio of oxygen and argon is 20:100, and the sputtering pressure is 3.5×10 -1 Pa, silicon boron is used as the target material, and the thickness of the deposited silicon oxide film is 15nm.

[0046] 2. Plating concave-convex nano-micro composite pore structure suede film layer: in the vacuum box, argon is used as the working gas, and the sputtering pressure is 3.5×10 -1 Pa, gallium-doped zinc oxide is used as the target material, and the deposited film thickness is 95nm.

[0047] 3. In the atmospheric environment, corrode the plated glass with hydrochloric acid with a weight concentration of 6% for 20 seconds, and the plated doped zinc oxide film layer forms a concave-convex nano-micro composite pore structure suede, and the pore size is 10-500nm; h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com