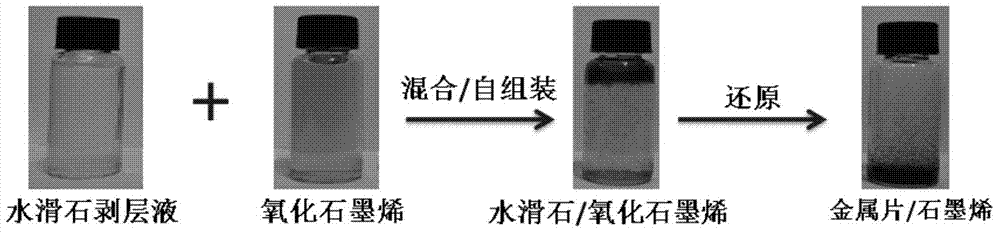

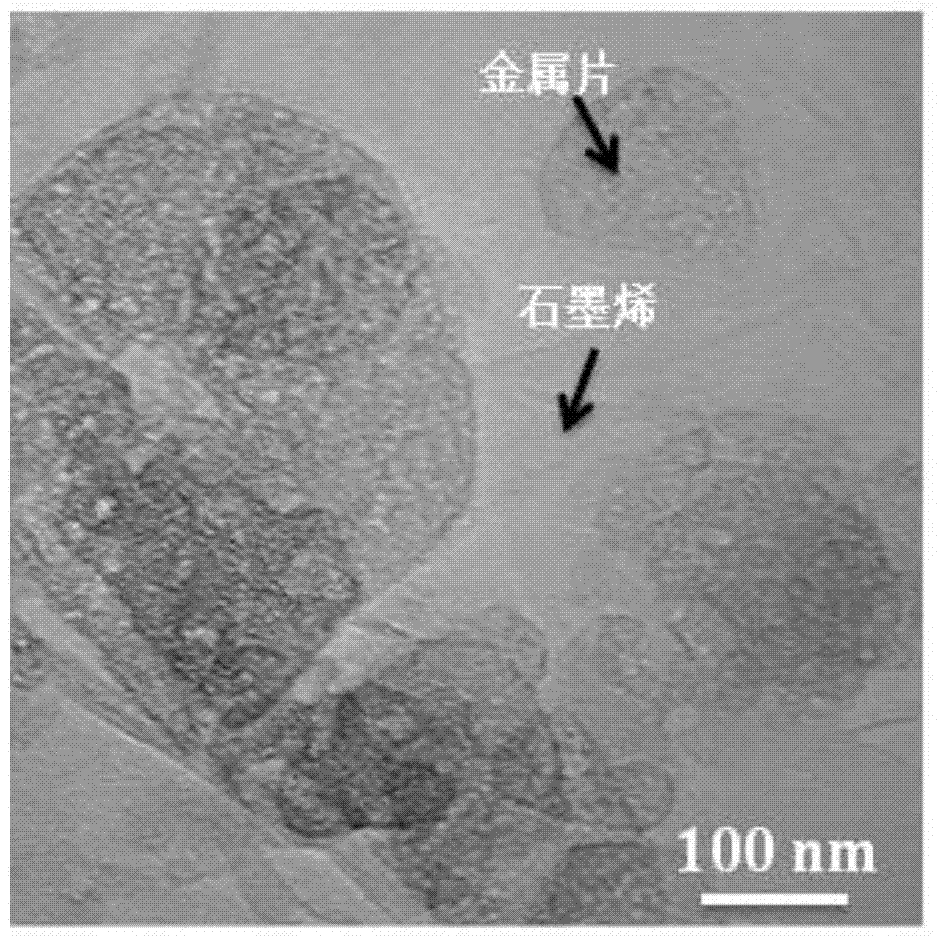

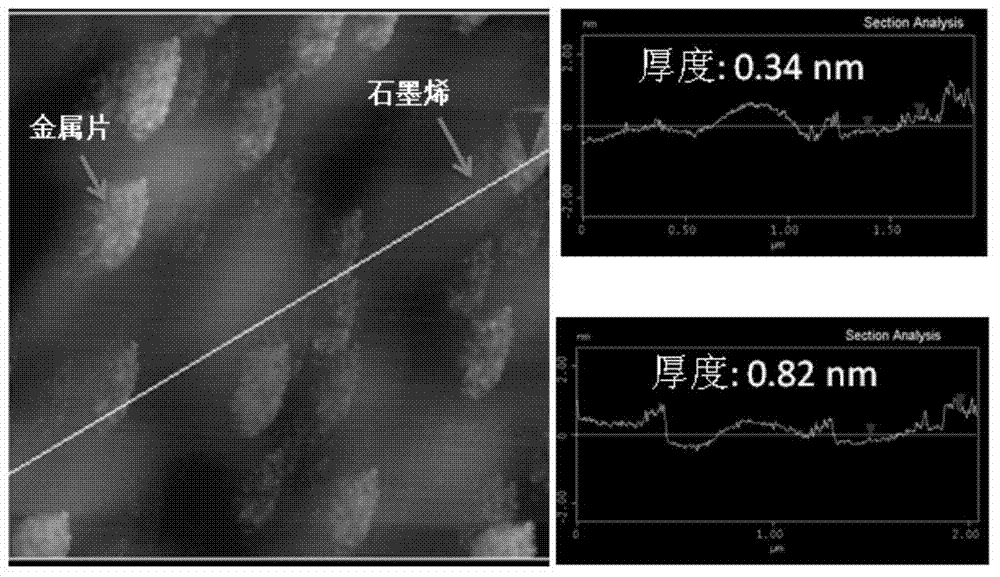

Preparation method of graphene-loaded ultrathin metal sheet with atomic-scale thickness

A graphene, atomic-level technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, nanotechnology for materials and surface science, etc. The problem of sufficient exposure of elemental atoms to achieve excellent electrical properties and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation of graphite oxide: Mix 3.0g of graphite powder and 1.5g of sodium nitrate in an ice-water bath, then add 69mL of concentrated sulfuric acid, and then add 9.0g of potassium permanganate under magnetic stirring; After stirring for 30 minutes, add 138 mL of deionized water, raise the temperature to 98°C, stir at a constant temperature for 15 minutes, then transfer to an ice-water bath to cool; finally pour it into a large beaker containing 420 mL of deionized water and 3 mL of 30 wt% hydrogen peroxide, 1000 r / min The upper layer liquid was taken by centrifugation, and dried in vacuum for 24 hours to obtain graphite oxide.

[0019] 1. The graphite oxide prepared above is ultrasonically dispersed in deionized water to obtain a 5 mg / L single-layer graphene oxide colloidal sol;

[0020] 2.a: Add 0.08mol nickel nitrate hexahydrate, 0.04mol aluminum nitrate nonahydrate and 0.4mol urea to 400mL deionized water, transfer to a polytetrafluoroethylene reactor after fully...

Embodiment 2

[0025] 1. the graphite oxide prepared by embodiment 1 is ultrasonically dispersed in deionized water to obtain a single-layer graphene oxide colloidal sol of 5 mg / L;

[0026] 2.a: Add 0.008mol cobalt nitrate hexahydrate, 0.004mol aluminum nitrate nonahydrate and 0.028mol urea to 800mL deionized water, and after fully dissolved, stir continuously for 48 hours in a water bath at 97°C under nitrogen protection, and wash the obtained solid with deionized water Wash with absolute ethanol for 3 times and dry under air condition to obtain carbonate intercalated cobalt aluminum hydrotalcite;

[0027] b: Dissolve 0.4 g of the solid obtained in step a, 0.6 mol of sodium nitrate and 0.002 mol of concentrated nitric acid with a mass fraction of 69.2% in 400 mL of deionized water, and continuously stir at room temperature for 24 h under nitrogen protection, and vacuum-dry the obtained solid after centrifugal washing. Obtain nitrate radical intercalation cobalt aluminum hydrotalcite;

[00...

Embodiment 3

[0031] 1. the graphite oxide prepared by embodiment 1 is ultrasonically dispersed in deionized water to obtain a single-layer graphene oxide colloidal sol of 5 mg / L;

[0032] 2.a: Add 0.005mol cobalt dichloride hexahydrate, 0.0025mol nickel dichloride hexahydrate and 0.045mol hexamethylenetetramine into 1000mL deionized water, and after fully dissolving, stir the above solution continuously under nitrogen protection and reflux for 5 hours, the obtained solid was washed 3 times with deionized water and absolute ethanol, and then dried under air conditions to obtain carbonate intercalated cobalt-nickel hydrotalcite;

[0033] b: Take 0.186 g of the solid obtained in step a, disperse it into an acetonitrile solution in which 0.00667 mol of bromine is dissolved, stir the mixture continuously at room temperature under nitrogen protection for 24 hours, wash the resulting solid with absolute ethanol for 5 times, and then vacuum-dry it to obtain bromide ions Intercalated cobalt nickel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com