Method for preparing polymer micro lens array

A microlens array and polymer technology, which is applied in the field of preparation of polymer microlens arrays, can solve the problems of difficult to guarantee the dimensional accuracy and shape of optical microlenses, long production cycle and high processing cost, and achieves low production cost and high processing cost. Short-time, easy-to-batch effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

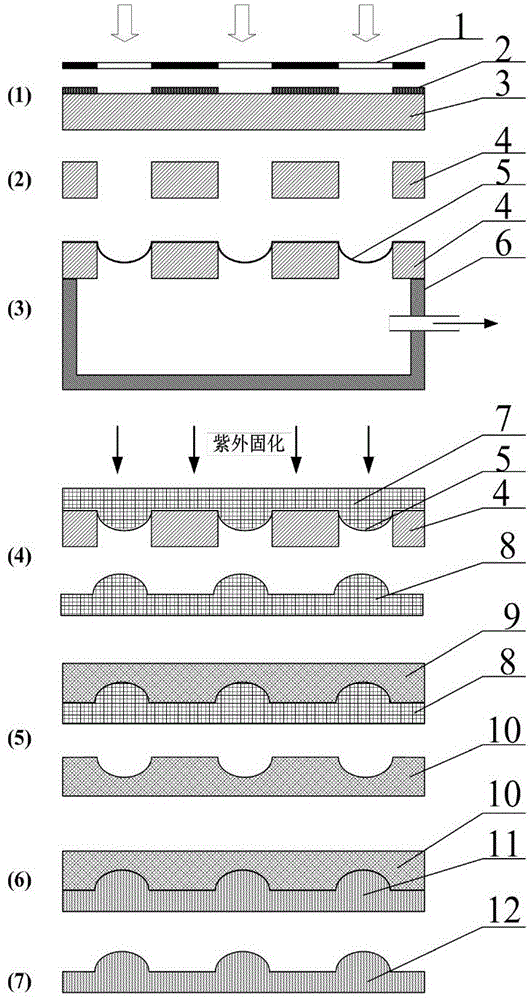

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] Such as figure 1 Shown, the preparation method of a kind of polymer microlens array of the present invention, comprises the following steps:

[0028] (1) Use the mask plate 1 to cover the surface of the silicon wafer substrate 3 with photoresist, and form a patterned photoresist mask 2 on the surface of the silicon wafer substrate 3 through exposure and development. The pattern on the photoresist mask 2 It is a photoresist microlens array pattern.

[0029] (2) By dry etching the pattern of the microlens array on the photoresist mask 2 , a microhole array 4 with the same diameter as the diameter of the microlens is formed on the silicon substrate 3 .

[0030] (3) Evenly cover the polydimethylsiloxane film 5 on the surface of the micropore array 4, and then seal the micropore array 4 with a cavity 6 that can generate negative pressure, so that the poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com