Preparation method of macromolecular water-absorbent resin with low reverse osmosis

A technology of superabsorbent resin and water-absorbent resin, applied in the field of sanitary products, can solve the problems of reduced stability of sanitary products, increased production cost, etc. The effect of improving polymerization stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

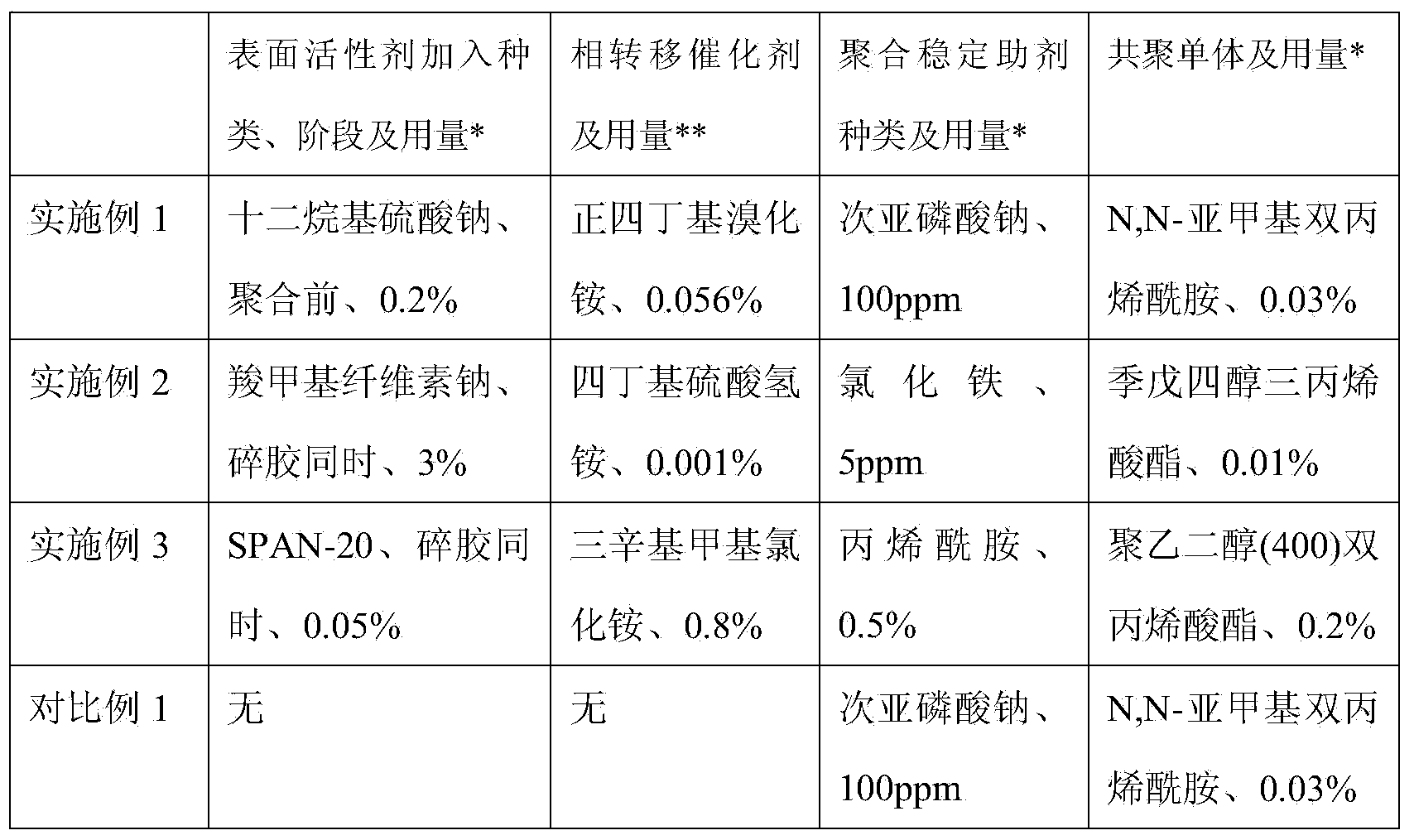

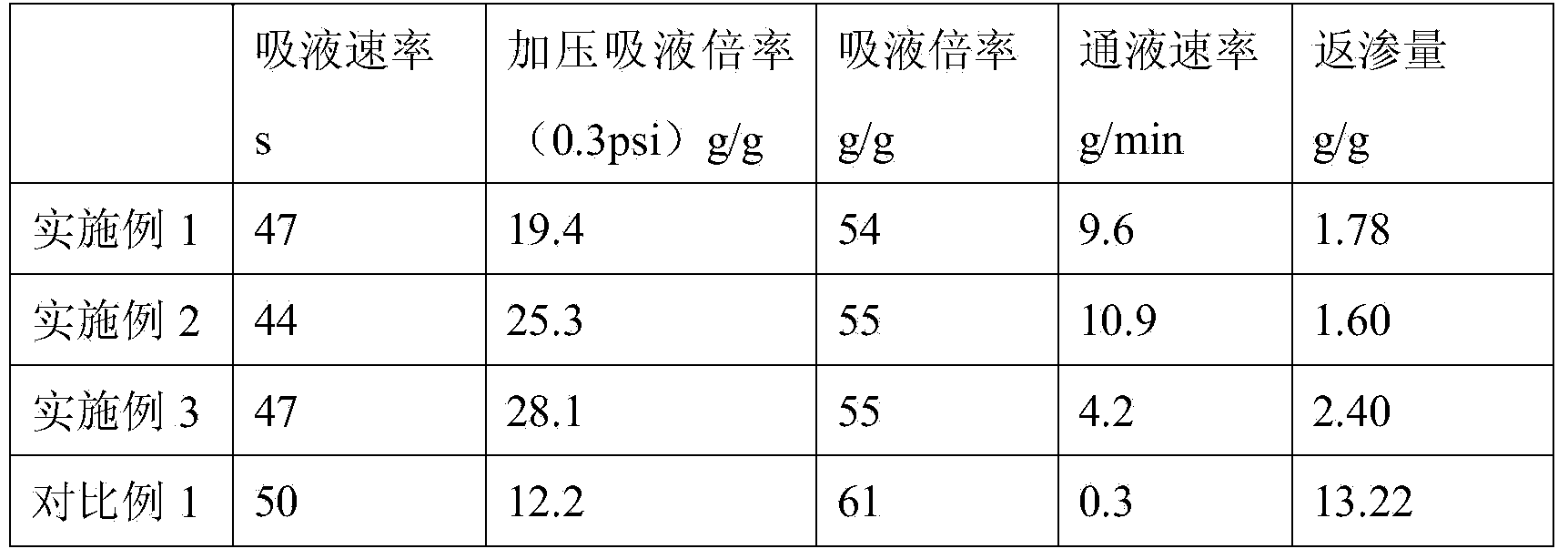

Embodiment 1

[0048] a) Add 30kg of acrylic acid and 10kg of deionized water into the reactor, start stirring, slowly add 14kg of 48% sodium hydroxide aqueous solution dropwise, and keep the temperature of the reactor at 20-40°C. After neutralization, add comonomer N,N-methylenebisacrylamide 9g, photocatalyst 1-hydroxycyclohexyl phenyl ketone 0.01kg, thermal initiator ammonium persulfate 34.2g, 30% hydrogen peroxide 10g, ten Dialkyl sodium sulfate 60g and sodium hypophosphite 3g, continue to fully stir. Cool the reaction kettle to keep the temperature of the reaction solution at about 5°C.

[0049] b) Pour the low-temperature mixed material into a trapezoidal polymerization tank, so that the height of the material is 1cm-5cm. The reaction material is irradiated with ultraviolet light, the initiation temperature is about 5°C, and the irradiation time is 18s; then the reaction solution continues to react and continue to heat up. When the temperature reaches 100°C (the polymerization has last...

Embodiment 2

[0054] a) Add 30kg of acrylic acid and 17kg of deionized water into the reactor, start stirring, slowly add 21kg of 48% sodium hydroxide aqueous solution dropwise, and keep the temperature of the reactor at 20-40°C. After neutralization, add comonomer pentaerythritol triacrylate 3g, photocatalyst phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide 15g, thermal initiator ammonium persulfate 36g and 5ppm chloride Iron, continue to stir well. Cool the reaction kettle to keep the temperature of the reaction solution at about 10°C.

[0055] b) Pour the low-temperature mixed material into a trapezoidal polymerization tank, so that the height of the material is 1cm-5cm. Use ultraviolet light to irradiate the reaction material, the trigger temperature is controlled at about 10°C, and the irradiation time is 40s; then the reaction solution continues to react and continue to heat up, when the temperature reaches 130°C, it starts to cool down, when the surface temperature of the colloid ...

Embodiment 3

[0060] a) Add 30kg of acrylic acid and 15kg of deionized water into the reactor, start stirring, slowly add 26kg of 48% sodium hydroxide aqueous solution dropwise, and keep the temperature of the reactor at 5-15°C. After neutralization, 60 g of comonomer polyethylene glycol (400) diacrylate, 1 g of photocatalyst 1-hydroxycyclohexyl phenyl ketone, 15 g of di-tert-butyl peroxide and 150 g of acrylamide were added, and the stirring was continued sufficiently. Cool the reaction kettle to keep the temperature of the reaction solution at about 10°C.

[0061] b) Pour the low-temperature mixed material into a trapezoidal polymerization tank, so that the height of the material is 1cm-5cm. Use ultraviolet light to irradiate the reaction material, the initiation temperature is controlled at about 10°C, and the irradiation time is 10s; then the reaction solution continues to react and continue to heat up, when the temperature reaches 100°C (the polymerization has lasted for 30 minutes at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com