Cataplasm used for inner electrode and laminated ceramic electronic part using the same

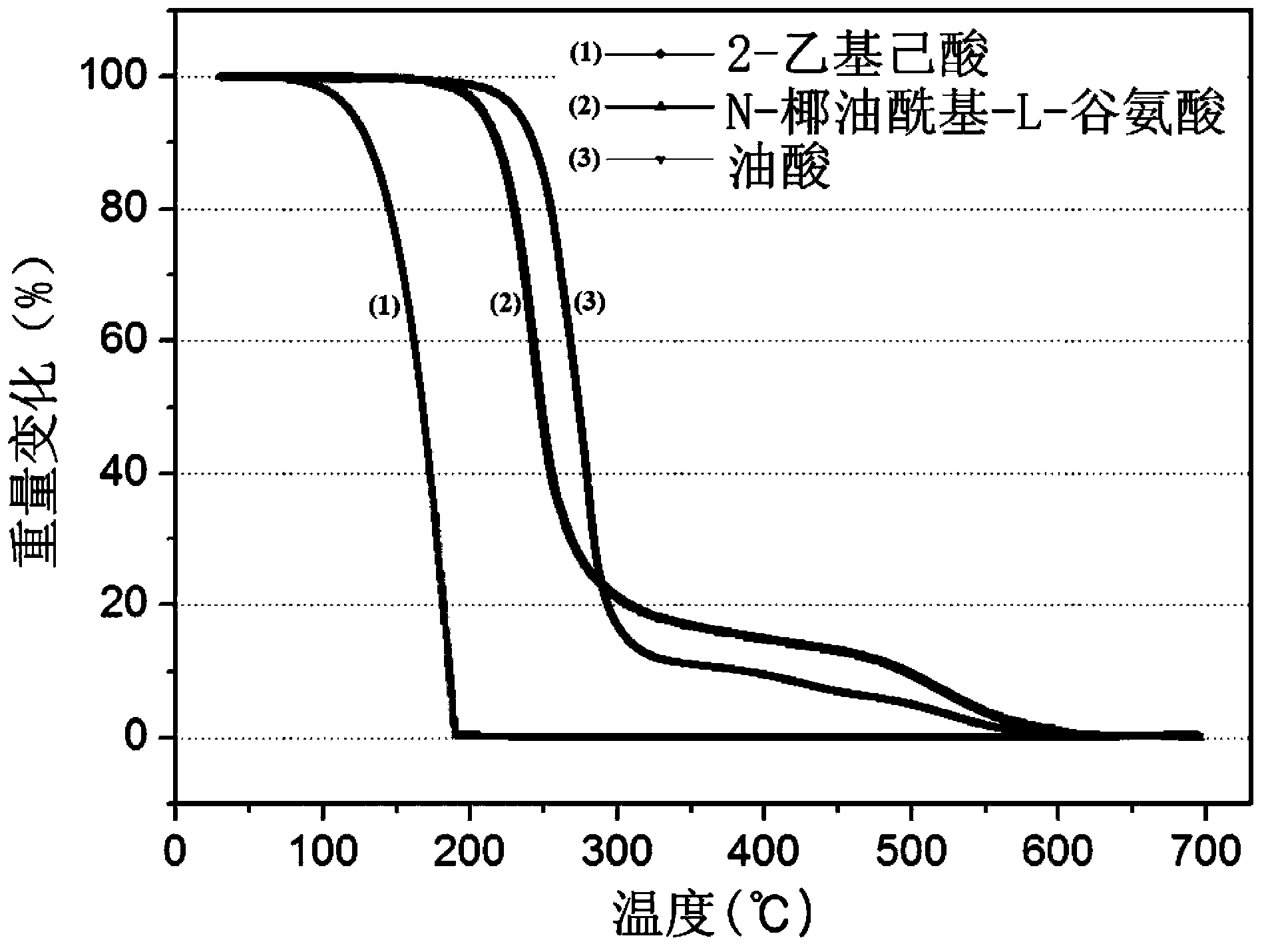

A technology of internal electrodes and pastes, applied to fixed capacitor parts, conductive materials dispersed in non-conductive inorganic materials, electrical components, etc., can solve lamination misalignment, reduce printing film adhesion and stickiness Combined force, deterioration and other problems, to achieve the effect of solving gelation phenomenon and viscosity increase, good thermal decomposition, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

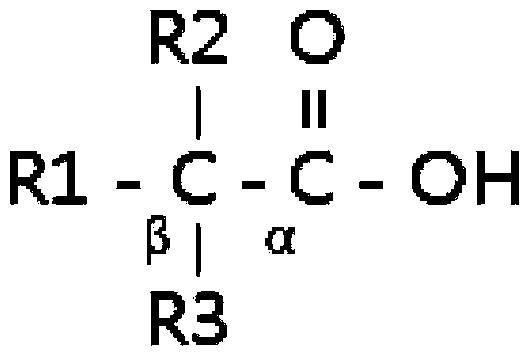

[0042] Nickel powder with an average particle size of 200nm is used as electrode material powder, dihydroterpineol acetate (DHTA) is used as solvent, barium titanate powder with an average particle size of 50nm is used as ceramic powder, and binder resin is used Ethyl cellulose and 2-ethylhexanoic acid were used as a dispersant, and a paste for internal electrodes was prepared by a generally used method. The above paste for internal electrodes is prepared by predispersing and mixing with a three-roll mill (3-roll mill).

Embodiment 2

[0044] A paste for internal electrodes was prepared by the same method as in Example 1 above, wherein neodecanoic acid was used as a dispersant instead of 2-ethylhexanoic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com