A kind of wood lacquer for purifying formaldehyde and preparation method thereof

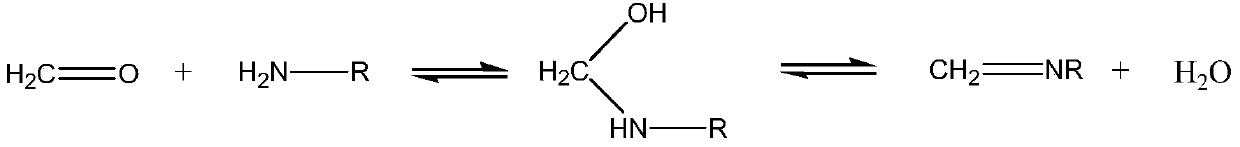

A technology of wood lacquer and formaldehyde, which is applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems of excessive curing speed, consumption of aldehyde groups, and difficulty in good film formation, so as to achieve no secondary Secondary pollution, simple process flow, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

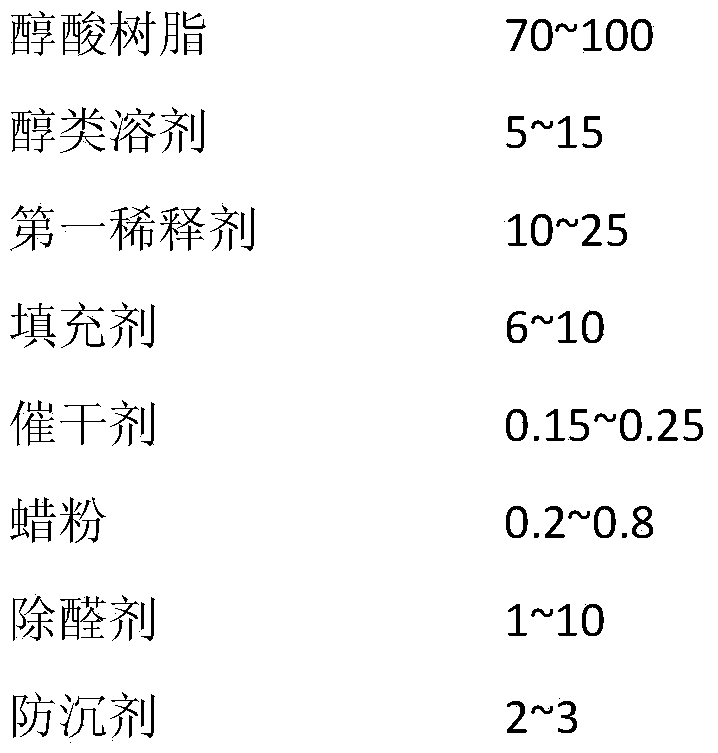

[0057] In parts by mass, the wood lacquer for purifying formaldehyde is prepared according to the following composition:

[0058] Preparation of Component A:

[0059]

[0060]

[0061] 1) Under nitrogen protection, put YTM3970 fatty acid modified quick-drying alkyd resin, ethanol, and ethylene glycol into the reaction kettle in proportion, stir evenly, and heat to 75°C;

[0062] 2) Add n-butyl acetate, cyclohexanone, organic bentonite, fumed silica, nano-alumina, dibutyltin dilaurate, polyethylene wax micropowder, chlorinated paraffin micropowder, phloroglucinol, hyperbranched Polyamidoamine, continue to stir, keep the temperature at 70°C for 15 minutes to make the reaction complete;

[0063] 3) After returning to room temperature, the material is discharged to obtain component A, which is sealed and stored in a cool place away from light.

[0064] Preparation of Component B:

[0065]

[0066] Preparation steps: 1) Under the protection of nitrogen, put n-butyl acet...

Embodiment 2

[0069] In parts by mass, the wood lacquer for purifying formaldehyde is prepared according to the following composition:

[0070] Preparation of Component A:

[0071]

[0072]

[0073] 1) Under the protection of nitrogen, put YTM3680 synthetic fatty acid resin, methanol and ethanol into the reaction kettle in proportion, stir evenly, and heat to 50°C;

[0074] 2) Add n-butyl acetate, ethyl acetate, organic bentonite, fumed silica, nano-aluminum oxide, zinc stearate, dibutyltin dilaurate, calcium naphthenate, polyethylene wax micropowder, chloride Paraffin micropowder, urea, 2‐imidazolidinone, barbituric acid, acetylacetone, phloroglucinol, terpineol, continue to stir, keep the temperature at 40°C for 60 minutes to complete the reaction;

[0075] 3) After returning to room temperature, the material is discharged to obtain component A, which is sealed and stored in a cool place away from light.

[0076] Preparation of Component B:

[0077]

[0078] Preparation steps:...

Embodiment 3

[0081] In parts by mass, the wood lacquer for purifying formaldehyde is prepared according to the following composition:

[0082] Preparation of Component A:

[0083]

[0084] 1) Under the protection of nitrogen, put YTM3170 coconut oleic acid modified short oil alkyd resin, methanol, ethanol, 1,4-butanediol into the reaction kettle in proportion, stir evenly, and heat to 62.5°C;

[0085] 2) Add n-butyl acetate, ethyl acetate, organic bentonite, talcum powder, nano-aluminum oxide, zinc stearate, dibutyltin dilaurate, zinc naphthenate, oxidized polyethylene wax micropowder, chlorinated paraffin in sequence Micropowder, polyamidoamine, 2-imidazolidinone, phloroglucinol, amide-modified castor oil, continue to stir, keep the temperature at 55°C for 37.5 minutes to complete the reaction;

[0086] 3) After returning to room temperature, the material is discharged to obtain component A, which is sealed and stored in a cool place away from light.

[0087] Preparation of Component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com