Preparation method of super-lubricity amorphous carbon film with nano-structure

A nano-structured and ultra-lubricating technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve problems affecting target film deposition, etc., and achieve good vacuum lubrication performance, uniform atmosphere, and smooth surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Cleaning the substrate: First, ultrasonically clean the monocrystalline silicon wafer (N100 type silicon wafer) with absolute ethanol and acetone solution for 10.0 min each, blow dry with nitrogen and place it in the reaction chamber; Vacuum; single crystal silicon wafer sputtering cleaning: when the background pressure of the deposition chamber is lower than 5.0×10 -4 Pa, pass argon gas in the deposition chamber, and use argon (Ar) plasma to sputter and clean the single crystal silicon wafer under the conditions of duty ratio of 50.0%-70.0% and pulsed DC negative bias voltage of 700.0-1000.0 V. 30.0min to remove the oxide layer and other impurities on the surface; deposition: mix methane gas and argon gas at a ratio of 1:7 and pass them into the reaction chamber, and turn on the radio frequency power supply (power 400.0~700.0 W), jointly sputtering a mixed target composed of aluminum and silicon (the area ratio is A 铝 / A 硅 =1 / 8), at the same time, a negative bias of...

Embodiment 2

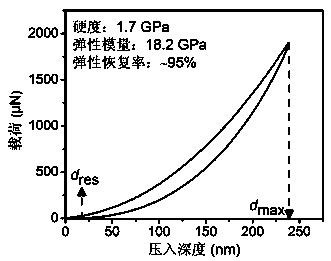

[0024] Field emission scanning electron microscopy was used to observe the cross section of the film, and it was found that the film was uniform, dense, and well bonded to the substrate. The thickness of the metal titanium transition layer in the sample layer was 150-350 nm, and the thickness of the amorphous carbon film layer was 2-4 μm. Observation of the thin film by high-resolution transmission electron microscopy revealed that the film contains dual structure features of fullerene-like and nano-network (attached figure 1 and figure 2 ). Nanoindentation experiments show that the elastic recovery performance of the film is excellent, the elastic recovery rate is as high as 95%, and the nano hardness is 1.0-2.0 GPa. X-ray photoelectron spectroscopy (XPS) was used to characterize the composition of the film, in which the carbon atomic percentage was 70-91.5 at.%; the oxygen atomic percentage was 2-15.5 at.%; the silicon atomic percentage was 1-10.0 at.%; The percentage is ...

Embodiment 3

[0026] At air pressure below 2.0×10 -4 Tribological tests were carried out in a vacuum environment of Pa. The contact mode between the thin film sample and the dual material (stainless steel ball with a diameter of 3-10.0mm) is ball-on-disk contact, and the motion mode is rotary, with a radius of rotation of 6.0 mm. The sliding linear velocity is 0.32 m / s, and the load is 2.0 N. The friction strokes are respectively controlled at 15000 rpm and 30000 rpm, and the friction curves are shown in the attached image 3 It can be seen that the friction coefficient can be as low as 0.001, and the wear rate can be as low as 10 -19 m 3 / N·m order of magnitude, see the attached Figure 4 In the upper right illustration of , the wear scar depth is about 100 nm, indicating that the film has excellent anti-wear performance under vacuum conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com