Production process for preparing sulfur by recovering sulfur dioxide from flue gas

A sulfur dioxide and production process technology, applied in the field of flue gas purification, can solve the problems of high desorption steam consumption, easy blockage of heat exchangers, poor desulfurization effect, etc., and achieve the effects of low system resistance, good economic benefits, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

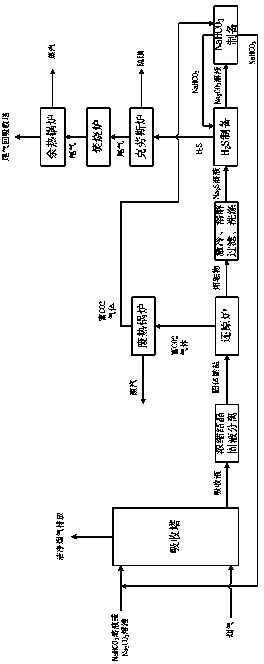

[0027] A production process for recovering sulfur dioxide from flue gas to produce sulfur, the specific steps are as follows:

[0028] A. The flue gas is desulfurized by sodium carbonate solution in the absorption tower, and the absorption liquid after interacting with the flue gas is concentrated and crystallized to separate the solid sodium salt;

[0029] B. Send the solid sodium salt into the reducer, and under the action of the reducing agent, the solid sodium salt is reduced to sodium sulfide; the molten mixture from the reducer is chilled, dissolved, filtered and washed, and the resulting clear liquid is an aqueous solution of sodium sulfide ; CO-rich exhaust from the reducer 2 After the gas is recovered by the waste heat boiler to generate steam, it is sent to the next step for processing;

[0030] C, add sodium bicarbonate in the gained sodium sulfide aqueous solution of B step, react gained H 2 The S gas is sent into the Claus furnace to manufacture sulfur products;...

Embodiment 2

[0032] A production process for recovering sulfur dioxide from flue gas to produce sulfur, the specific steps are as follows:

[0033] A. The flue gas is desulfurized by sodium bicarbonate solution in the absorption tower, and the absorption liquid after interacting with the flue gas is concentrated and crystallized to separate the solid sodium salt;

[0034] B. Send the solid sodium salt into the reducer, and under the action of the reducing agent, the solid sodium salt is reduced to sodium sulfide; the molten mixture from the reducer is chilled, dissolved, filtered and washed, and the resulting clear liquid is an aqueous solution of sodium sulfide ; CO-rich exhaust from the reducer 2 After the gas is recovered by the waste heat boiler to generate steam, it is sent to the next step for processing;

[0035] C, add sodium bicarbonate in the gained sodium sulfide aqueous solution of B step, react gained H 2 The S gas is sent into the Claus furnace to manufacture sulfur product...

Embodiment 3

[0037] The implementation mode of this embodiment is basically the same as embodiment 1, on this basis:

[0038] The molten mixture from the reducer is chilled, dissolved, filtered and washed, and the solid waste obtained is sent to the boiler as fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com