Antibacterial protection bag for water purification equipment

A technology of water purification equipment and protective bags, applied in the direction of filtration separation, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of ineffective removal, human hazards, secondary pollution of water purifiers, etc., and achieve the purpose of inhibiting microorganisms growth, good mechanical properties, and the effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Taking the antibacterial protective cover and the ultrafiltration membrane filter element in the water purification equipment as an example, this patent is further described in detail:

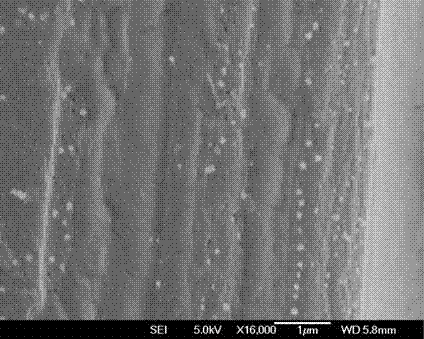

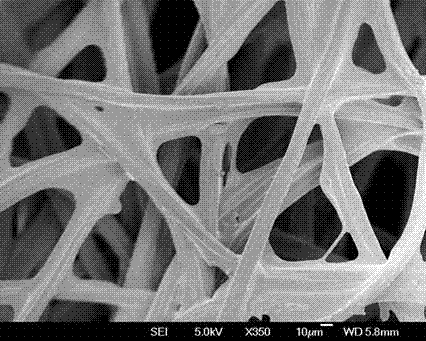

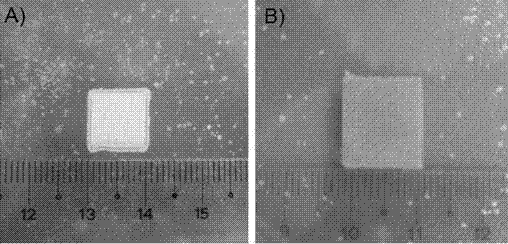

[0020] Use viscose (70%) non-woven fabric as the substrate, wash it with deionized water several times, soak it in silver acetate (1wt%) aqueous solution for 5 hours, take it out and wash it, and place it in glucose aqueous solution (5wt%) Soak for 1.5 hours, take it out and wash it several times with deionized water to obtain nano silver antibacterial fibers. The electron microscope irradiation test of the nano-silver antibacterial fiber confirmed that the nano-silver material was granular, about 100 nanometers ( figure 2 ). Such as Figure 4 As shown, the antibacterial fiber has a loose and porous structure. Subsequently, the antibacterial fiber with a size of 1 cm × 1 cm was cut and the plate method was used to detect the antibacterial zone together with the blank fiber. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com