Production system of suspended-state calcined coal gangues

A technology for calcining coal gangue and a production system, which is applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc. The effect of uniform quality, high production efficiency and fast heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

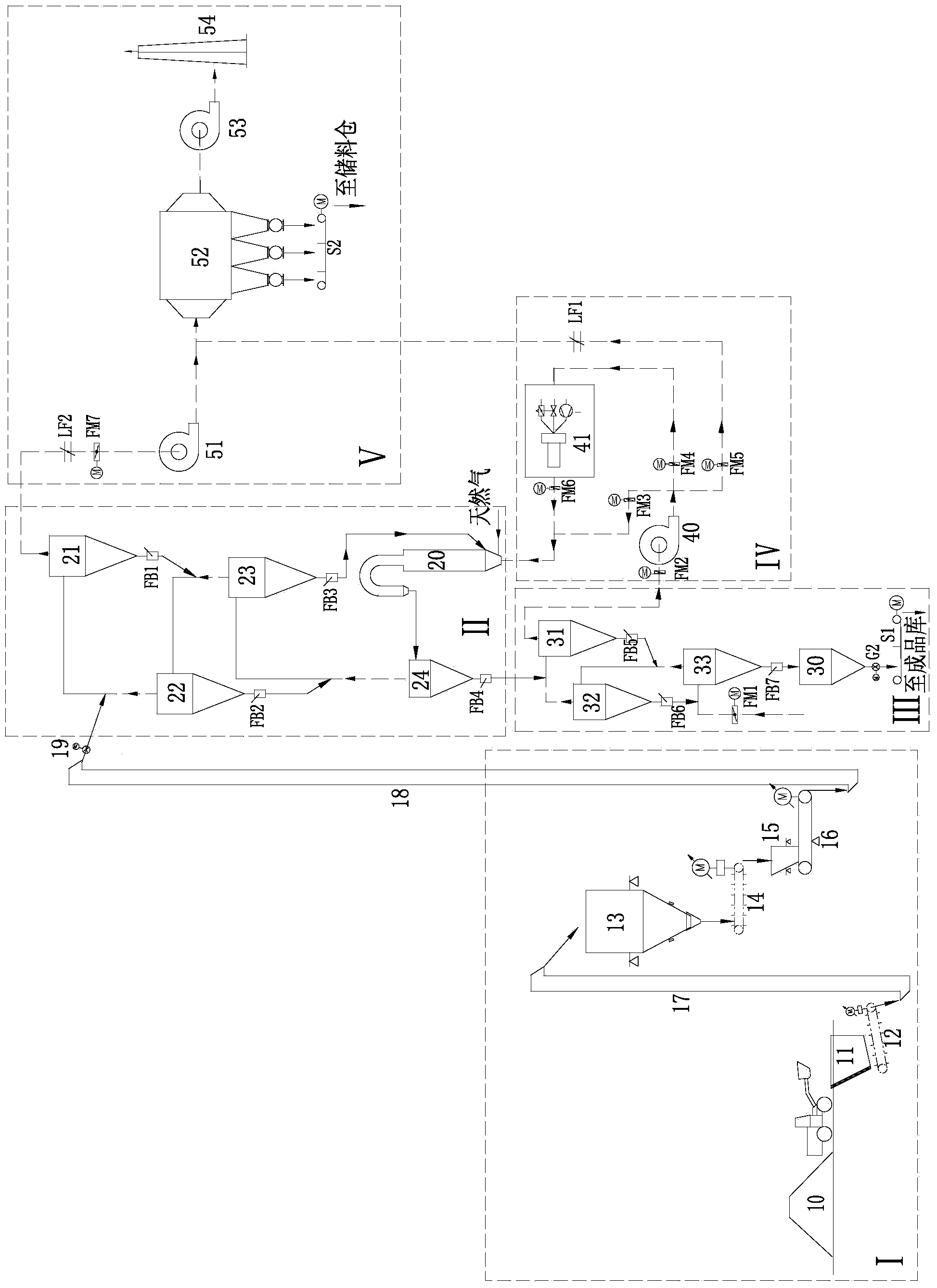

[0024] Such as figure 1 As shown, a production system of suspended calcined coal gangue in the present invention includes raw material preparation and feeding subsystem I, preheating and calcining furnace subsystem II, product cooling and heat recovery subsystem III, hot air preparation and supply subsystem Ⅳ and system power and exhaust gas purification subsystem Ⅴ.

[0025] Among them, the raw material preparation and feeding subsystem I includes a first-level frequency conversion speed regulation feeder 12 with a hopper 11 on the top, and the output of the frequency conversion speed regulation feeder 12 is sent to the storage bin 13 through a bucket elevator 17 , the bottom outlet of the storage bin 13 is provided with a secondary frequency conversion speed regulation feeder 14, the outlet of the frequency conversion speed regulation feeder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com