A welding process suitable for inconel600 alloy

A welding process and alloy technology, which is applied in the field of Inconel600 alloy welding process, can solve the problems of unsatisfactory high-temperature mechanical properties of welds, hidden dangers in the stability and safety of Inconel600 alloy products, etc., and achieve excellent performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

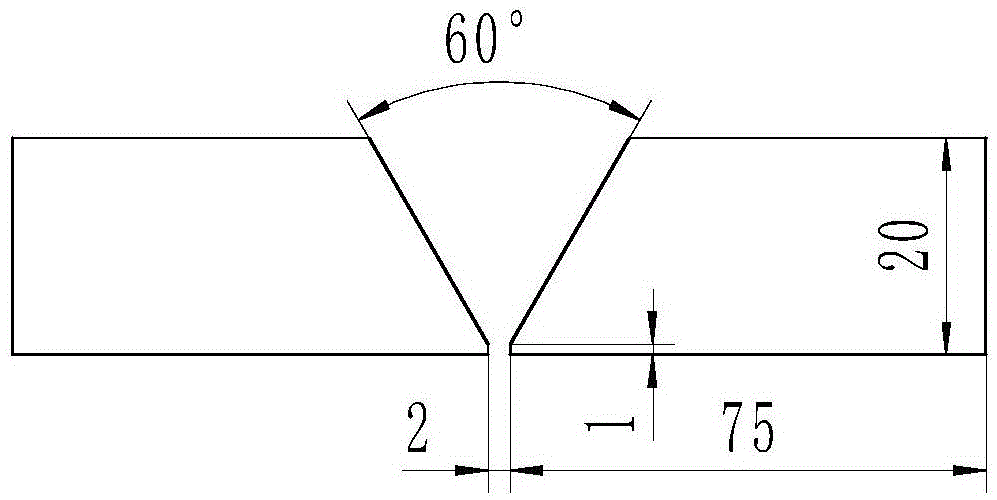

[0022] Two Inconel600 rolled plates with specifications of 450mm×75mm×20mm were selected as welding samples, and a V-shaped butt joint groove was adopted. The groove type was: the length of the blunt side was 1mm, and the groove angle was 60°. docking structure such as figure 1 shown.

[0023] To weld the above welding samples, the welding machine model used is WSM-4000 inverter pulse argon arc welding machine; the welding material used is welding wire with a diameter of φ2.4mm, and its composition is: C 0.03%, Cr 16.8% , Fe 7.2%, Mn 0.4%, Nb 2.45%, Si 0.85%, S 0.002%, P 0.002%, Ni balance.

[0024] The welding process includes the following steps:

[0025] (1) Clean the surface of the groove to be welded of the welding sample, keep it clean and dry, then connect the groove according to the above-mentioned butt joint method, fix the position with spot welding, and then pass argon gas for protection; the welding machine and the to-be-welded The sample is connected in a direc...

Embodiment 2

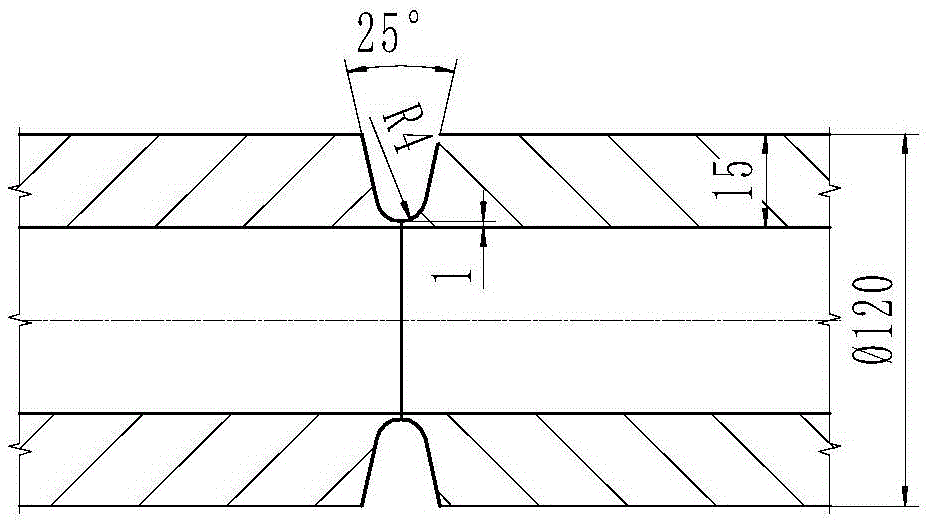

[0029] Two Inconel600 pipe sections with specifications of φ120mm (outer diameter) × 15mm (wall thickness) × 150mm (length) were selected as welding samples, and a U-shaped butt joint groove was adopted. Mouth angle 25°. The docking structure is attached figure 2 shown.

[0030] The above welding samples were welded using the same welding consumables and equipment as in Example 1.

[0031] The welding process includes the following steps:

[0032] (1) Clean the surface of the groove to be welded of the welding sample, keep it clean and dry, then connect the groove according to the above-mentioned butt joint method, fix the position with spot welding, and then pass argon gas for protection; the welding machine and the to-be-welded The sample is connected in a direct current connection;

[0033] (2) Carry out bottom welding on the welding sample, the welding current is 90A, the voltage is 12V, the welding speed is about 0.8mm / s, and two layers are welded;

[0034] (3) Carr...

Embodiment 3

[0035] Example 3 (comparison)

[0036] Using the same welding sample, butt joint method and equipment as in Example 1, it was welded with ERNiCr-3 welding wire with a diameter of φ2.4mm as the welding material.

[0037] The welding process includes the following steps:

[0038] (1) Clean the surface of the groove to be welded of the welding sample, keep it clean and dry, then connect the groove according to the above-mentioned butt joint method, fix the position with spot welding, and then pass argon gas for protection; the welding machine and the to-be-welded The sample is connected in a direct current connection;

[0039] (2) Underground welding is performed on the sample to be welded, the welding current is 110A, the voltage is 15V, the welding speed is about 1.1mm / s, and two layers are welded;

[0040] (3) Carry out filling welding and cover welding, welding current 130A, voltage 20V, welding speed about 1.4mm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com