Manufacturing method of composite substrate structure used for nitride growth

A technology of a composite substrate and a manufacturing method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as the limitation of improving the light emitting rate of light-emitting diodes, affecting the brightness of light-emitting diodes, and complex processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Such as Figure 1 to Figure 7 As shown, this embodiment provides a method for manufacturing a composite substrate structure for nitride growth, which at least includes the following steps:

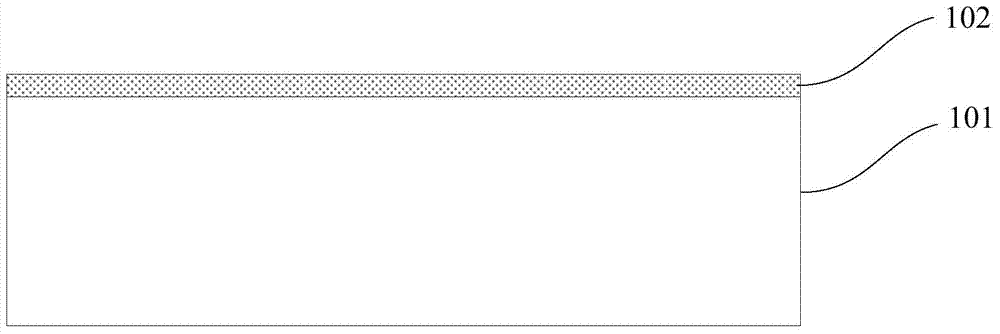

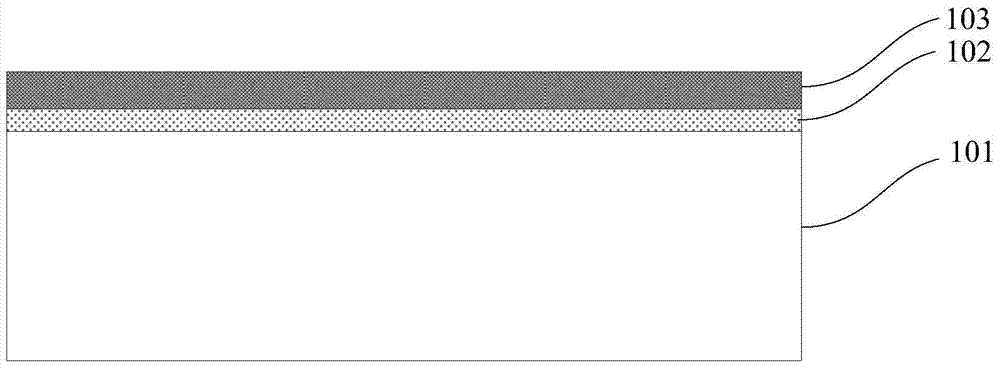

[0036] Such as Figure 1 ~ Figure 2 As shown, step 1) is firstly performed, a growth substrate 101 is provided, and a buffer layer 102 for subsequent growth of a light-emitting epitaxial structure is formed on the surface of the growth substrate 101 .

[0037] As an example, the material of the growth substrate 101 is one of sapphire, SiC, Si and ZnO. In this embodiment, the growth substrate 101 is a flat sapphire substrate with a flat surface. The buffer layer 102 is low-temperature Al prepared by low-temperature chemical vapor deposition. x Ga 1-x N layer (0≤X≤0.5), preferably low temperature Al x Ga 1-x For N layers (0≤X≤0.2), the temperature range for preparation is 450-700°C. In this example, the low temperature Al x Ga 1-x The preparation temperature of the N layer (0≤...

Embodiment 2

[0049] Such as Figure 1 to Figure 6 and Figure 8 As shown, this embodiment provides a method for manufacturing a composite substrate structure for nitride growth, the basic steps of which are as in Embodiment 1, wherein:

[0050] The buffer layer 102 is an AlN layer prepared by a sputtering method, and the crystal orientation or main crystal orientation of the AlN layer is (0001) orientation. Compared to low temperature Al x Ga 1-x N layer, the advantage of sputtering AlN layer preparation is strong controllability of thickness, high degree of crystal orientation, and it is also conducive to the nucleation and growth of light-emitting epitaxial structures (especially GaN-based light-emitting epitaxial structures).

[0051] As another solution of this embodiment, the buffer layer 102 is a BN material layer prepared by methods such as sputtering.

[0052] Such as Figure 8 As shown, in this embodiment, the plurality of hole structures 106 are arranged in a hexagonal array...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com