Traffic control circuit welding welding-assisting material and preparing method thereof

A traffic control and circuit technology, which is applied in the direction of welding/cutting medium/material, welding equipment, welding medium, etc., can solve the problems of decreased welding strength, poor oxidation resistance of welding materials and solder, and affecting quality, so as to improve the high resistance Low temperature characteristics, improved anti-aging performance, and the effect of ensuring welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In the present embodiment, 26 parts of ethanol, 3.2 parts of methanol, 2.6 parts of diethylene glycol ether, 1.8 parts of o-hydroxybenzoic acid, 2.3 parts of paraffin, 56.8 parts of deionized water, 6 parts of rosin, and 1.3 parts of sodium dodecylbenzenesulfonate share.

[0021] The preparation method of the above-mentioned traffic control circuit soldering flux material specifically includes the following steps:

[0022] a In the container A with stirring function, add diethylene glycol ethyl ether, o-hydroxybenzoic acid and paraffin successively in parts by weight, then start the stirrer at a speed of 80 rpm under 25°C and stir for 30 minutes until The paraffin is completely dissolved, and then the mixed liquid A is filtered out with a 200-mesh fineness filter for subsequent use;

[0023] b In container B with stirring function, add ethanol, methanol, and rosin in parts by weight, start the agitator at a rate of 80 rpm at room temperature and stir for 120 minutes ...

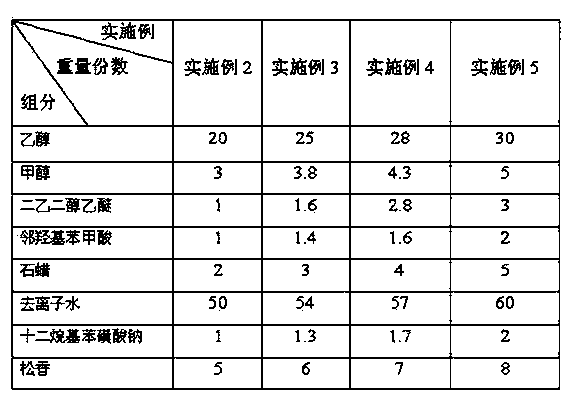

Embodiment 2~ Embodiment 5

[0028] Each component and preparation method in embodiment 2~embodiment 5 are all the same as embodiment 1, and the difference is only that the parts by weight of each component are different, specifically as shown in the following table:

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com