Preparation method for producing adenosine-containing lucid ganoderma extract piece by liquid fermentation

A technology of liquid fermentation and Ganoderma lucidum extract, which is applied to medical preparations containing active ingredients, pharmaceutical formulas, sugar-coated pills, etc., can solve the problems of insufficient hardness, loose tablets, poor stability, etc., and achieves a stable content determination method. Dissolution of the agent and the effect of ensuring bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A preparation method for producing adenosine-containing Ganoderma lucidum extract sheet by liquid fermentation:

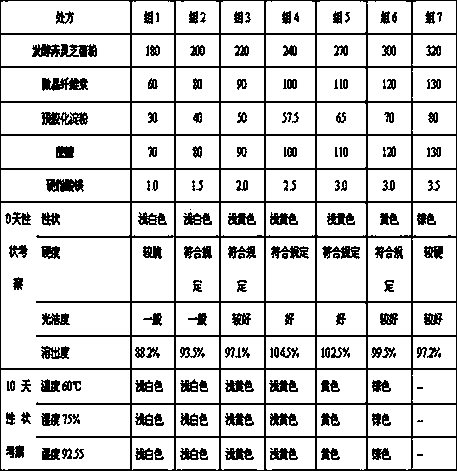

[0069] Among them, the weight ratio of each raw material is: fermented red ganoderma fungus powder 200 microcrystalline cellulose 80 pregelatinized starch 40 sucrose 80 magnesium stearate 1.5;

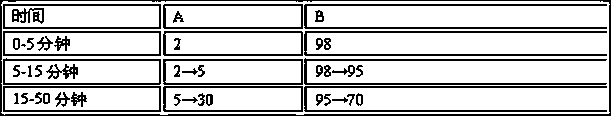

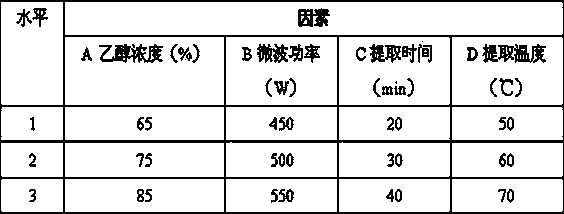

[0070] Preparation of fermented Ganoderma lucidum powder: Take the liquid fermentation product of Ganoderma lucidum, filter it, and concentrate the filtrate to a thick paste with a relative density of 1.05 (65°C); the residues are extracted with 60% ethanol microwave, the microwave power is 450w, and the extraction temperature is 50°C ℃℃, extract twice, the amount of ethanol is 6 times the weight of the residue, the extraction time is 20min, combine the secondary extracts, recover the ethanol and concentrate it into a thick paste, combine with the thick paste of the above fermentation liquid, stir well, and concentrate under reduced pressure to 65°C Relative density ...

Embodiment 2

[0073] A preparation method for producing adenosine-containing Ganoderma lucidum extract sheet by liquid fermentation:

[0074] Among them, the weight ratio of each raw material is: fermented ganoderma lucidum powder 240 microcrystalline cellulose 100 pregelatinized starch 57.5 sucrose 100 magnesium stearate 2.5;

[0075] Preparation of fermented Ganoderma lucidum powder: Take the liquid fermentation product of Ganoderma lucidum, filter it, and concentrate the filtrate to a thick paste with a relative density of 1.10 (65°C); the residue is extracted by microwave with 75% ethanol, the microwave power is 550W, and the amount of ethanol is 7 times the weight of the residue, extraction temperature 70°C, extraction time 30min, extract twice, combine the second extracts, recover ethanol and concentrate into a thick paste, combine with the thick paste of the above fermentation liquid, stir well, and concentrate under reduced pressure to 65°C Density is the clear ointment of 1.23, and...

Embodiment 3

[0078] A preparation method for producing adenosine-containing Ganoderma lucidum extract sheet by liquid fermentation:

[0079] Wherein, the weight ratio of each raw material is: fermented red ganoderma fungus powder 300 microcrystalline cellulose 120 pregelatinized starch 70 sucrose 120 magnesium stearate 3.0;

[0080] Preparation of fermented Ganoderma lucidum powder: Take the liquid fermentation product of Ganoderma lucidum, filter it, and concentrate the filtrate to a thick paste with a relative density of 1.15 (65°C); the residues are extracted by microwave with 90% ethanol, the microwave power is 550w, and the extraction temperature 70°C, extract twice, the amount of ethanol is 8 times the weight of the residue, the extraction time is 40min, combine the secondary extracts, recover the ethanol and concentrate into a thick paste, combine with the thick paste of the above fermentation broth, stir well, and concentrate under reduced pressure to 65°C Relative density is the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com