Method for preparing silver-tungsten carbide contact material from silver-coated tungsten carbide powder and silver-tungsten carbide contact material

A technology of silver-coated tungsten carbide and silver tungsten carbide, which is used in contacts, electrical components, electrical switches, etc., can solve the problems of unstable composition, uneven penetration of silver flakes, uneven metallographic structure of contact materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

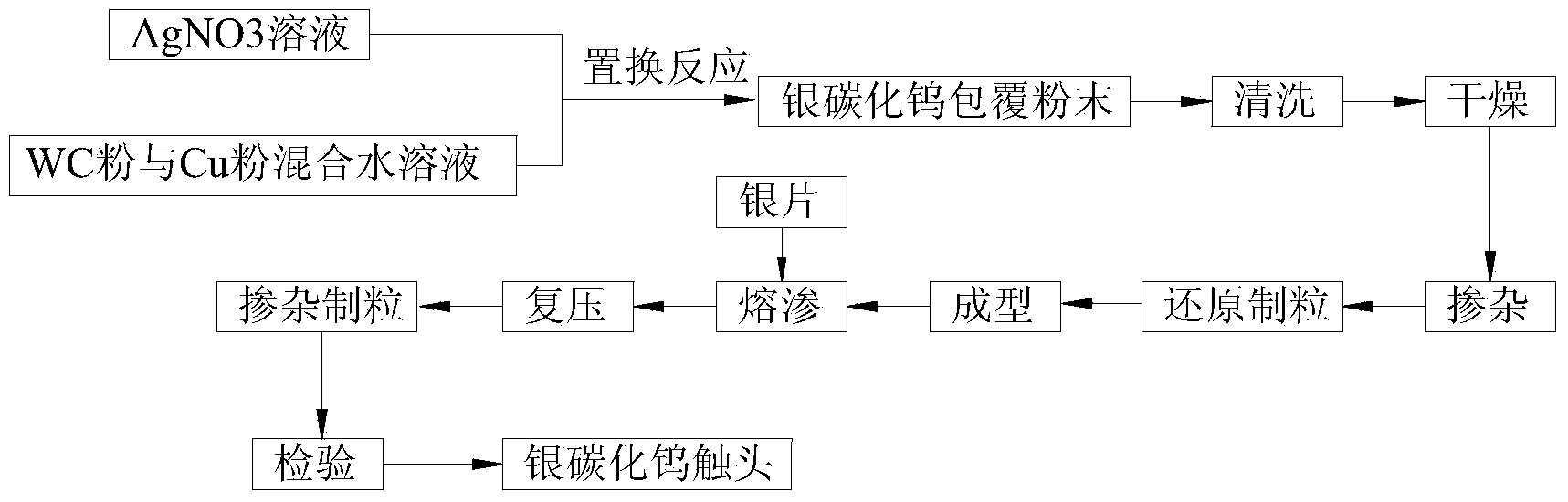

Method used

Image

Examples

Embodiment 1

[0025] 1. Prepare Ag50WC50 coating powder 5Kg

[0026] 1.1. Ag required for material preparation: 5×50%=2.5 Kg, thus calculating AgNO3 crystal: 2.5 / 0.6351=3.936 Kg (0.6351 is the molar mass ratio of silver to silver nitrate);

[0027] Required WC powder: 5×50%=2.5 Kg,

[0028] Required Cu powder: 2.5 / 3.4=0.735 Kg (from the replacement reaction equation, it is estimated that 1g of Cu replaces Ag by about 3.4g);

[0029] 1.2. Add 3.936 Kg of AgNO3 crystals into deionized water at 25-45°C, stir and dissolve with stainless steel to obtain AgNO3 solution, so that the molar concentration of AgNO3 solution is 5-7mol / L;

[0030] 1.3. Put WC powder and Cu powder into the reaction tank, add 10-15L of deionized water at 25-45°C, and stir evenly for 5 minutes to obtain a mixed aqueous solution;

[0031] 1.4. Slowly add the AgNO3 solution into the mixed aqueous solution under constant stirring until the AgNO3 solution is completely added, and continue to stir for 3 to 5 minut...

Embodiment 2

[0044] 1. Prepare Ag47WC53 coating powder 5Kg

[0045] 1.1. Ag required for material preparation: 5×47%=2.35 Kg, thus calculating AgNO3 crystal: 2.35 / 0.6351=3.7Kg (0.6351 is the molar mass ratio of silver to silver nitrate);

[0046] Required WC powder: 5×53%=2.65 Kg,

[0047]Required Cu powder: 2.35 / 3.4=0.691 Kg (from the replacement reaction equation, 1g of Cu replaces Ag with about 3.4g);

[0048] 1.2. Add 3.7Kg of AgNO3 crystals into deionized water at 25-45°C, stir and dissolve with stainless steel to obtain AgNO3 solution, so that the molar concentration of AgNO3 solution is 5-7mol / L;

[0049] 1.3. Put WC powder and Cu powder into the reaction tank, add 9.4-14.1L of deionized water at 25-45°C, and stir evenly for 5 minutes to obtain a mixed aqueous solution;

[0050] 1.4. Slowly add the AgNO3 solution into the mixed aqueous solution under constant stirring until the AgNO3 solution is completely added, and continue to stir for 3 to 5 minutes to carry out a chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com