Radiation-proof yarn and production method thereof

A technology of anti-radiation and yarn, which is applied in the direction of yarn, stretch spinning, textiles and papermaking, etc., can solve the problems of poor anti-radiation performance and flexibility, easy to break antibacterial effect, unsatisfactory and other problems, and achieve low cost and difficult Fracture antibacterial effect, effect of improving antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of anti-radiation yarn, which is formed by blending metal wire, polyacrylonitrile fiber and viscose fiber according to the weight ratio of 1:5:4; the metal wire is prepared according to the following method:

[0024] 1) Put pyrite powder, copper powder, alumina powder and titanium carbide powder into the mixer, and stir evenly to obtain mixture 1. The particle size of the pyrite powder, copper powder, alumina powder and titanium carbide powder is controlled Above 800 mesh;

[0025] 2) Put the mixture 1 obtained in step 1) into the reaction tank, then add water glass, stir while adding, and stir for 5 minutes to obtain mixture 2, and control the temperature of the reactor to 200°C;

[0026] 3) Lower the temperature of the reaction tank to 100°C, then add borax, talc powder and silica gel to the reaction tank in sequence, and stir evenly to obtain mixture 3;

[0027] 4) Put the mixture 3 obtained in step 3) into a graphite mold, and then put it into a high-tempera...

Embodiment 2

[0031] A kind of anti-radiation yarn, which is formed by blending metal wire, polyacrylonitrile fiber and viscose fiber according to the weight ratio of 1:5:4; the metal wire is prepared according to the following method:

[0032] 1) Put pyrite powder, copper powder, alumina powder and titanium carbide powder into the mixer, and stir evenly to obtain mixture 1. The particle size of the pyrite powder, copper powder, alumina powder and titanium carbide powder is controlled Above 800 mesh;

[0033] 2) Put the mixture 1 obtained in step 1) into the reaction tank, then add water glass, stir while adding, and stir for 5 minutes to obtain mixture 2, and control the temperature of the reactor to 200°C;

[0034] 3) Lower the temperature of the reaction tank to 100°C, then add borax, talc powder and silica gel to the reaction tank in sequence, and stir evenly to obtain mixture 3;

[0035] 4) Put the mixture 3 obtained in step 3) into a graphite mold, and then put it into a high-tempera...

Embodiment 3

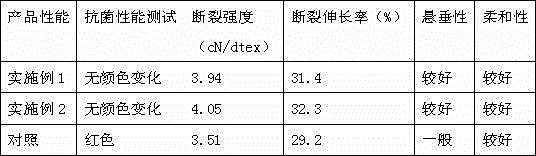

[0039] 1. The performance test of the anti-radiation yarn prepared by the present invention: use CN103243427A to prepare the metal wire blended yarn as a control. The performance parameters of the test are shown in Table 1.

[0040] Table 1

[0041]

[0042] Conclusion: The antibacterial performance test of textiles adopts the AATCC spray method (for specific operation methods, please refer to "Testing Methods and Standards for Textile Testing Performance, Dyeing and Finishing Technology 2007"), and it is found that the antibacterial yarn of the present invention has antibacterial effect, breaking strength and fracture The elongation rate is also better than that of the control group, and the drapability and soft performance are better.

[0043] 2. the anti-radiation knit sweater that the anti-radiation yarn prepared in embodiment 1 is woven is tested by China Shanghai Testing Center, and the results are shown in Table 2:

[0044] Freque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com