A kind of preparation method of metal organic framework MOF-2 polycrystalline film

A metal-organic framework, MOF-2 technology, applied in the field of preparation of metal-organic framework MOF-2 polycrystalline film, to achieve the effect of high effective quality, simple process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

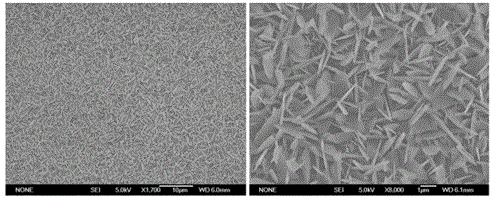

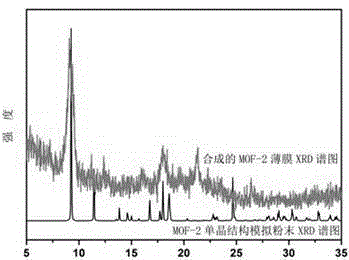

Image

Examples

Embodiment 1

[0018] A metal organic framework material MOF-2 polycrystalline film, the preparation steps are as follows:

[0019] Step 1, cut the zinc sheet with a thickness of 1mm into a rectangle of 1cm×2.5cm, and use 1000 # , 2000 # 、5000 # Grind with water-resistant sandpaper and cerium oxide polishing powder until the surface is smooth, that is, the surface of the zinc sheet is smooth and clean without scratches, protrusions or burrs, then ultrasonically clean the zinc sheet in 95% ethanol for 20 minutes, and dry at 80°C for later use .

[0020] Step 2, put 0.4g of terephthalic acid in a mixed solvent of 40ml of ethanol and water, the volume ratio of ethanol and water is 3:1, stir at room temperature for 0.5 hours to obtain a saturated solution of terephthalic acid, filter to remove terephthalic acid undissolved solid terephthalic acid in a saturated solution of dicarboxylic acid to obtain a clear saturated solution of terephthalic acid.

[0021] Step 3, with the zinc sheet descri...

Embodiment 2

[0025] A metal organic framework material MOF-2 polycrystalline film, the preparation steps are as follows:

[0026] Step 1, cut the zinc sheet with a thickness of 0.5mm into a rectangle of 1cm×2.5cm, and use 1000 # , 2000 # 、5000 # Water-resistant sandpaper and cerium oxide polishing powder are used to polish the surface until the surface is smooth, that is, the surface of the zinc sheet is smooth and clean without scratches, protrusions or burrs. Then, the zinc sheet is ultrasonically cleaned in 95% volume concentration ethanol for 30 minutes, and dried at 60°C for later use.

[0027] Step 2, put 0.4g of terephthalic acid in a mixed solvent of 40ml of ethanol and water, the volume ratio of ethanol and water is 4:1, stir at room temperature for 1 hour to obtain a saturated solution of terephthalic acid, filter to remove terephthalic acid undissolved solid terephthalic acid in a saturated solution of dicarboxylic acid to obtain a clear saturated solution of terephthalic acid...

Embodiment 3

[0030] A metal organic framework material MOF-2 polycrystalline film, the preparation steps are as follows:

[0031] Step 1, cut the zinc sheet with a thickness of 1mm into a rectangle of 1cm×2.5cm, and use 1000 # , 2000 # 、5000 # Grind the surface with water-resistant sandpaper and cerium oxide polishing powder until the surface is smooth, that is, the surface of the zinc sheet is smooth and clean without scratches, protrusions or burrs, then ultrasonically clean the zinc sheet in 95% ethanol with a volume concentration of 15 minutes, and dry at 80°C for later use .

[0032] Step 2, put 0.4g of terephthalic acid in a mixed solvent of 40ml of ethanol and water, the volume ratio of ethanol and water is 3:1, stir at room temperature for 1 hour to obtain a saturated solution of terephthalic acid, filter to remove terephthalic acid undissolved solid terephthalic acid in a saturated solution of dicarboxylic acid to obtain a clear saturated solution of terephthalic acid.

[0033...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com