Engineering strain for biologically producing ferulic acid and establishing method of engineering strain

A construction method and technology for engineering strains, applied in the directions of bacteria, introduction of foreign genetic material using vectors, recombinant DNA technology, etc., can solve the problems of difficult separation, long reaction time, etc., and achieve high production efficiency, high industrialization value, and by-products less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

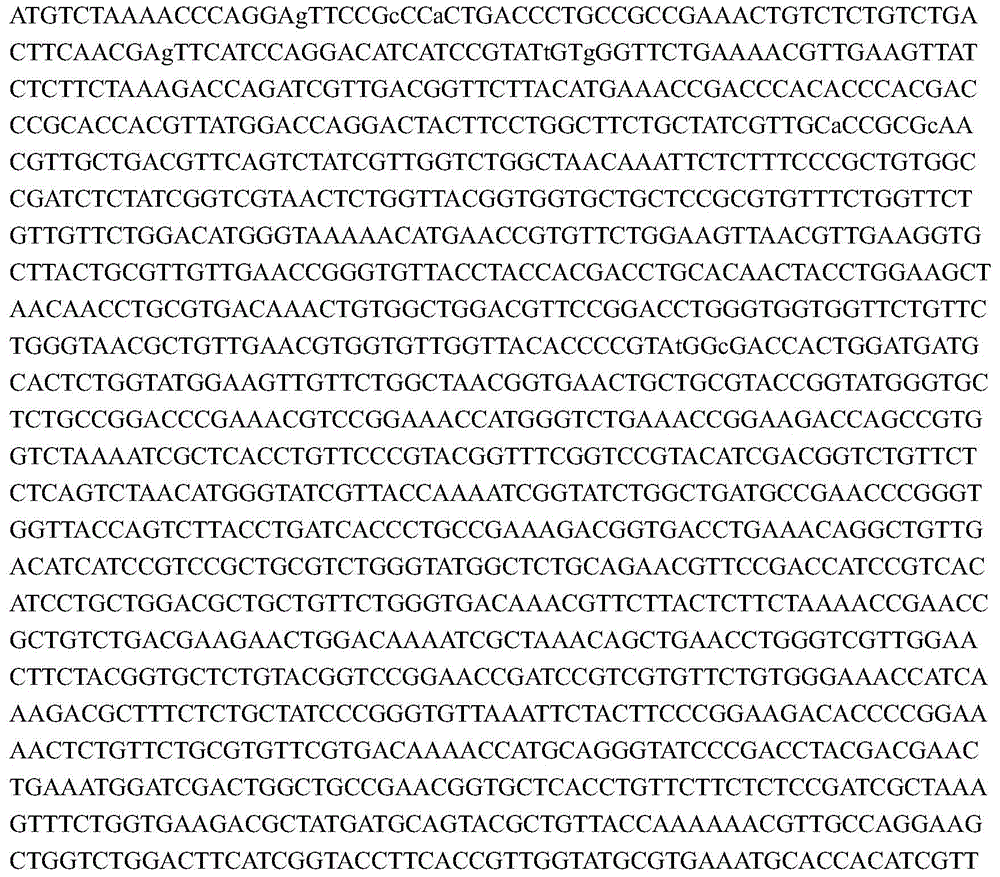

Image

Examples

Embodiment 1

[0037] Embodiment 1: Construction and identification of recombinant strains

[0038] 1. Construction of strains containing recombinant plasmid pET24a-vaoA

[0039] 1) Plasmid construction

[0040] Plasmid pET24a(+): a product of Novagen, with a size of 5.31kb, containing a kanamycin resistance gene, a lactose repressor lac I gene, a T7 promoter, and multiple restriction endonuclease sites.

[0041] The DNA fragment of the vanillyl oxidase gene (vaoA, 1683bp) was digested with Nde I and Bam HI. The vector pET24a(+) was double digested with Nde I and Bam HI. Enzyme digestion system: 43 μL DNA, 5 μL buffer R, 1 μL Bam HI, 1 μL Nde I, incubated at 37°C for 3 hours.

[0042] The enzyme-digested DNA fragments were gel recovered, and the vaoA and carrier DNA fragments were ligated with T4 ligase. The ligation system was as follows: vaoA 7.5 μL, pET24a vector 1.5 μL, buffer 1 μL, T4 ligase 1 μL, incubated overnight at 16°C, and the ligated products were heat-shocked Transformed in...

Embodiment 2

[0056] Embodiment 2: the fermentation of recombinant bacterial strain

[0057] Mix 100mL of seed solution, the seed solution contains 1% peptone, 0.5% yeast extract, 1% sodium chloride, and the balance is purified water. After being sterilized in a 250mL Erlenmeyer flask, inoculate a single colony on the plate medium, and the shaker rotation speed is 200rpm / min. After culturing at 37°C for 16 hours, inoculate into a 500mL Erlenmeyer flask containing 200mL fermentation broth, which contains 1.2% peptone, 2.4% yeast extract, 0.4% glycerin, 0.23% potassium dihydrogen phosphate, 1.25% dipotassium hydrogen phosphate, The balance is purified water. Fermentation culture conditions: Inoculate according to 1% of the fermentation volume, culture at 37°C, shaker rotation speed is 200rpm / min, after 1.5 hours after inoculation, cool down to 25-28°C, add final concentration of 0.6mM IPTG, and cultivate for 8 hours.

Embodiment 3

[0058] Embodiment 3: catalysis eugenol generates ferulic acid

[0059] After the fermentation, collect the cells by centrifugation at 4000rpm / min at 4°C, suspend the cells with 100mL of phosphate buffer, transfer them to a 250mL transformation bottle, add 0.06mL of eugenol, the transformation conditions are 25°C, and the rotation speed of the shaker is 200rpm / min, and 0.06 mL of eugenol substrate was added in batches every hour. After 8-10 hours, the yield of ferulic acid and the complete conversion of eugenol were detected by high performance liquid chromatography (HPLC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com