Process for decomposing gypsum through spraying and fluidizing

A spouted fluidized bed, gypsum technology, applied in the chemical industry, inorganic chemistry, sulfur compounds, etc., can solve the problems of inability to carry out industrial production, difficult operation, low device operation rate, etc., and achieve easier control and enhancement of material decomposition. Heat and mass transfer effect, the effect of large material contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

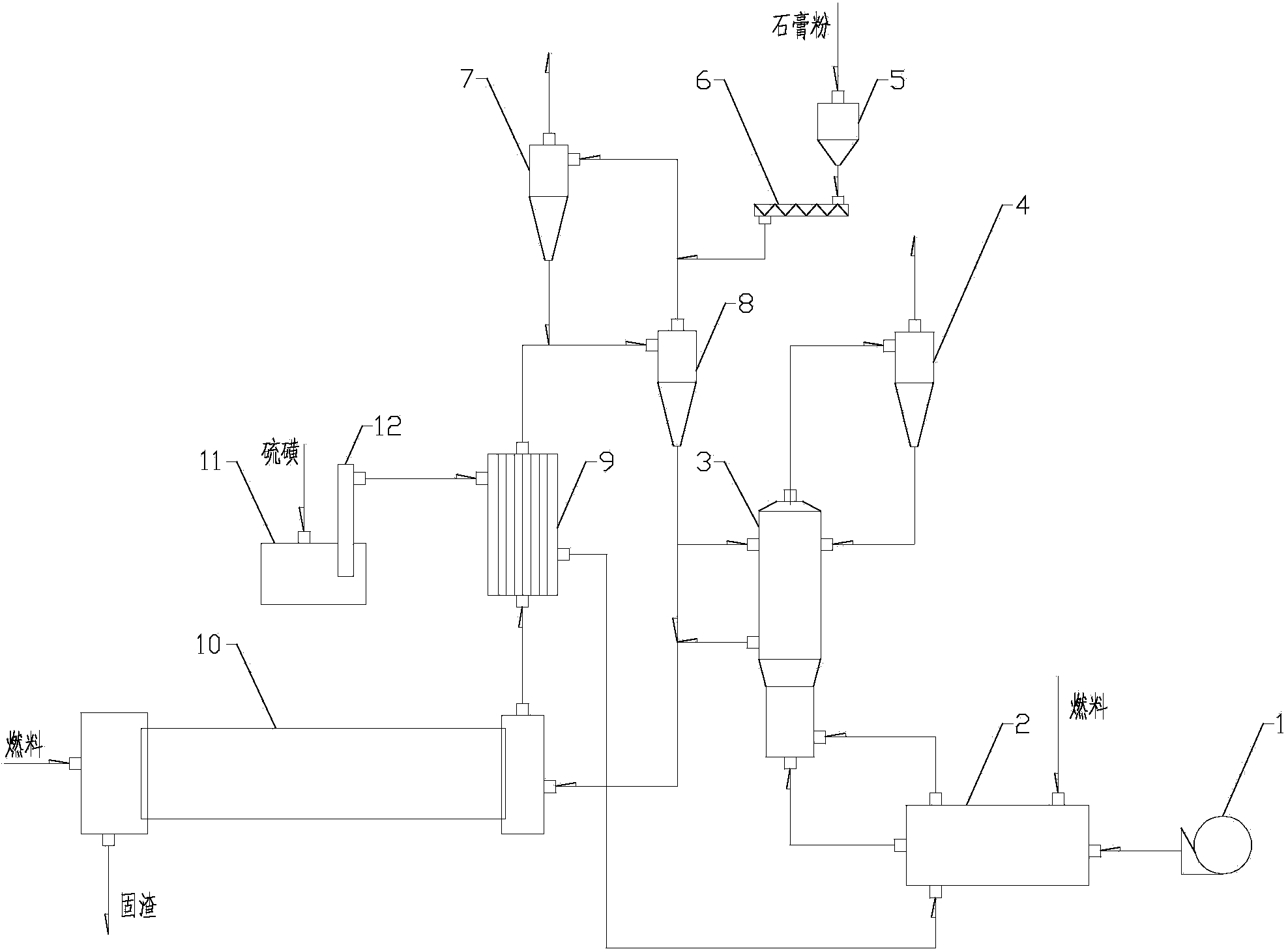

Method used

Image

Examples

Embodiment 1

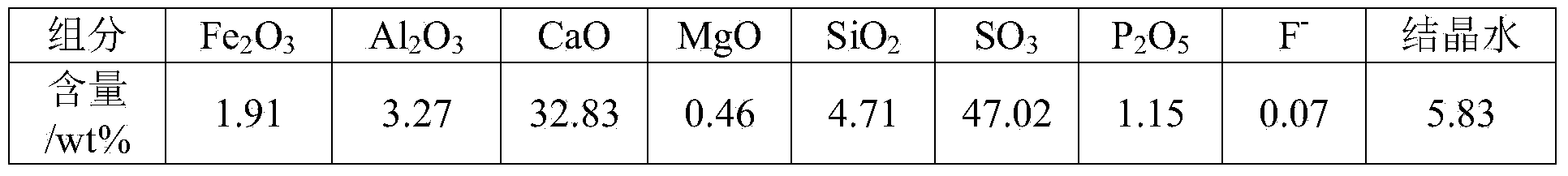

[0042] Raw material 1: Phosphogypsum powder hemihydrate. Table 1 shows its chemical composition.

[0043] Raw material 2: sulfur (purity 99.8wt%)

[0044] Table 1 Chemical composition of phosphogypsum powder hemihydrate

[0045]

[0046] Fuel: natural gas. Table 2 shows its chemical composition.

[0047] Table 2 Chemical composition of natural gas

[0048] components

[0049] The solid sulfur is indirectly heat-exchanged with saturated water vapor in the sulfur melting tank 11 to obtain liquid sulfur at 150°C; The waste heat tail gas is subjected to indirect heat exchange, so that the liquid sulfur is gasified into sulfur vapor at 550°C, which is sent to the hot blast stove 2, and the waste heat tail gas enters the secondary cyclone preheater 8; the gypsum raw meal powder with an average particle size of 50 μm in the silo 5 is mixed with The volume ratio of the flue gas under standard conditions is 1:6000. The feeder 6 is fed into the primary cyclone preheate...

Embodiment 2

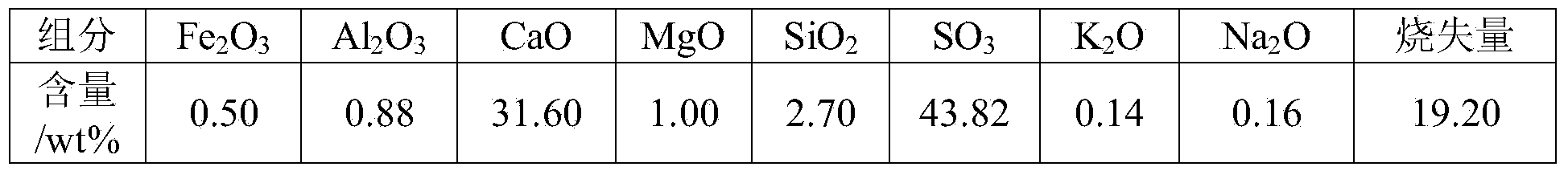

[0051] Raw material 1: desulfurized gypsum powder. Table 1 shows its chemical composition.

[0052] Raw material 2: sulfur (purity 99.8wt%)

[0053] Table 3 Chemical composition of desulfurized gypsum powder

[0054]

[0055] Fuel: Anthracite. Table 4 is its industrial analysis.

[0056] Table 4 Analysis of anthracite industry

[0057] components

[0058] The solid sulfur is indirectly heat-exchanged with saturated water vapor in the sulfur melting tank 11 to obtain liquid sulfur at 130°C; The waste heat tail gas is subjected to indirect heat exchange, so that the liquid sulfur is gasified into sulfur vapor at 450°C, which is sent to the hot blast stove 2, and the waste heat tail gas enters the secondary cyclone preheater 8; the gypsum raw meal powder with an average particle size of 120 μm in the silo 5 is mixed with The volume ratio of the flue gas under standard conditions is 1:4000. The feeder 6 is fed into the first-stage cyclone preheater 7, and the tem...

Embodiment 3

[0060] Raw material 1: salt gypsum powder. Table 5 is its chemical composition.

[0061] Raw material 2: sulfur (purity 99.8wt%)

[0062] Table 5 Chemical composition of salt gypsum powder

[0063]

[0064] Fuel: bituminous coal. Table 6 is its industrial analysis.

[0065] Table 6 Bituminous coal industry analysis

[0066] components

[0067] The solid sulfur is indirectly heat-exchanged with saturated water vapor in the sulfur melting tank 11 to obtain liquid sulfur at 130°C; The waste heat tail gas is subjected to indirect heat exchange, so that the liquid sulfur is gasified into sulfur vapor at 550°C, which is sent to the hot blast stove 2, and the waste heat tail gas enters the secondary cyclone preheater 8; the gypsum raw meal powder with an average particle size of 200 μm in the silo 5 is mixed with The volume ratio of the flue gas under standard conditions is 1:7000, fed into the first-stage cyclone preheater 7 through the feeder 6, and the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com