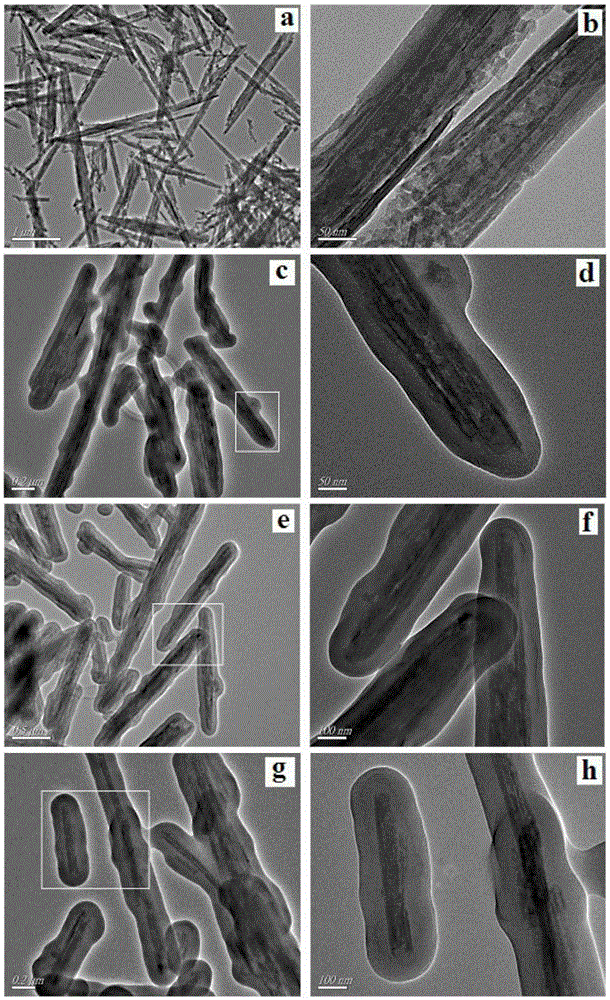

A Method for Controllable Preparation of Hollow Molecularly Imprinted Nanorods Using Halloysite as a Template

A technology of molecular imprinting and halloysite, which is applied in nanotechnology, chemical instruments and methods, and other chemical processes, can solve the problems of control, coating uniformity and thickness of difficult-to-polymerize layers, and achieve excellent regeneration performance, abundant reserves, Effect of good thermal and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Halloysite pretreatment and surface functionalization

[0029] According to the ratio of halloysite (HNTs):concentrated nitric acid:distilled water mass ratio of 1:4:25 (g / g / g), halloysite, distilled water and concentrated nitric acid were added to the flask in turn, ultrasonicated for 30min, placed in 80 o In a C oil bath, stir vigorously for 12 hours, filter with suction, wash with distilled water until neutral, and place at 100 o C oven drying to constant weight, to obtain the processed halloysite. According to the ratio of the treated halloysite: 3-(methacryloyloxy) propyltrimethoxysilane (KH570): toluene mass ratio of 1.0:1.0:100 (g / g / g), to the three-necked flask Add treated halloysite, 3-(methacryloyloxy)propyltrimethoxysilane and toluene in sequence, ultrasonically disperse evenly, place at 90 o In a C oil bath, the reaction was vigorously stirred for 12 hours. After the reaction, cooled to room temperature, the product was washed with toluene, ethanol and...

Embodiment 2

[0035] (1) Halloysite pretreatment and surface functionalization

[0036] According to the ratio of halloysite (HNTs):concentrated nitric acid:distilled water mass ratio of 1:6:25 (g / g / g), halloysite, distilled water and concentrated nitric acid were added to the flask in turn, ultrasonicated for 30min, and placed in 80 o In a C oil bath, stir vigorously for 12 hours, filter with suction, wash with distilled water until neutral, and place at 100 o C oven drying to constant weight, to obtain the processed halloysite. According to the ratio of the treated halloysite: 3-(methacryloyloxy) propyltrimethoxysilane (KH570): toluene mass ratio of 1.0:1.0:100 (g / g / g), to the three-necked flask Add treated halloysite, 3-(methacryloyloxy)propyltrimethoxysilane and toluene in sequence, ultrasonically disperse evenly, place at 90 o In a C oil bath, the reaction was vigorously stirred for 12 hours. After the reaction, cooled to room temperature, the product was washed with toluene, ethanol...

experiment example 1

[0045] Experimental Example 1: Take 10ml of chloramphenicol solutions with initial concentrations of 10, 50, 100, 150, 200, 300, 400, 500 and 600 μmol / L and add them to a centrifuge tube, add 10 mg of HMINs-1, HMINs-2, For HMINs-3 and HNINs-2, put the test solution in a 298K water bath and let it stand for 12.0h, then centrifuge to collect the supernatant, measure the molecular concentration of unadsorbed chloramphenicol with a UV-visible spectrophotometer, and calculate according to the results out the adsorption capacity. Such as Figure 7 As shown, the experimental results show that: with the increase of the concentration, the adsorption amount of chloramphenicol increases; the adsorption amount of chloramphenicol by hollow molecularly imprinted nanorods is greater than that of HNINs-2, showing good specific recognition and separation performance, indicating that there are active sites matching chloramphenicol molecules in the hollow molecularly imprinted nanorod polymer g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com