Continuous drying device and method for mesoporous powder material

A powder material and drying device technology, which is applied in the field of mesoporous powder materials, can solve the problems of increasing equipment costs, increasing the volume of drying kettles, and unfavorable large-scale industrial production, and achieves cost reduction, small bulk density, and pore maintenance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

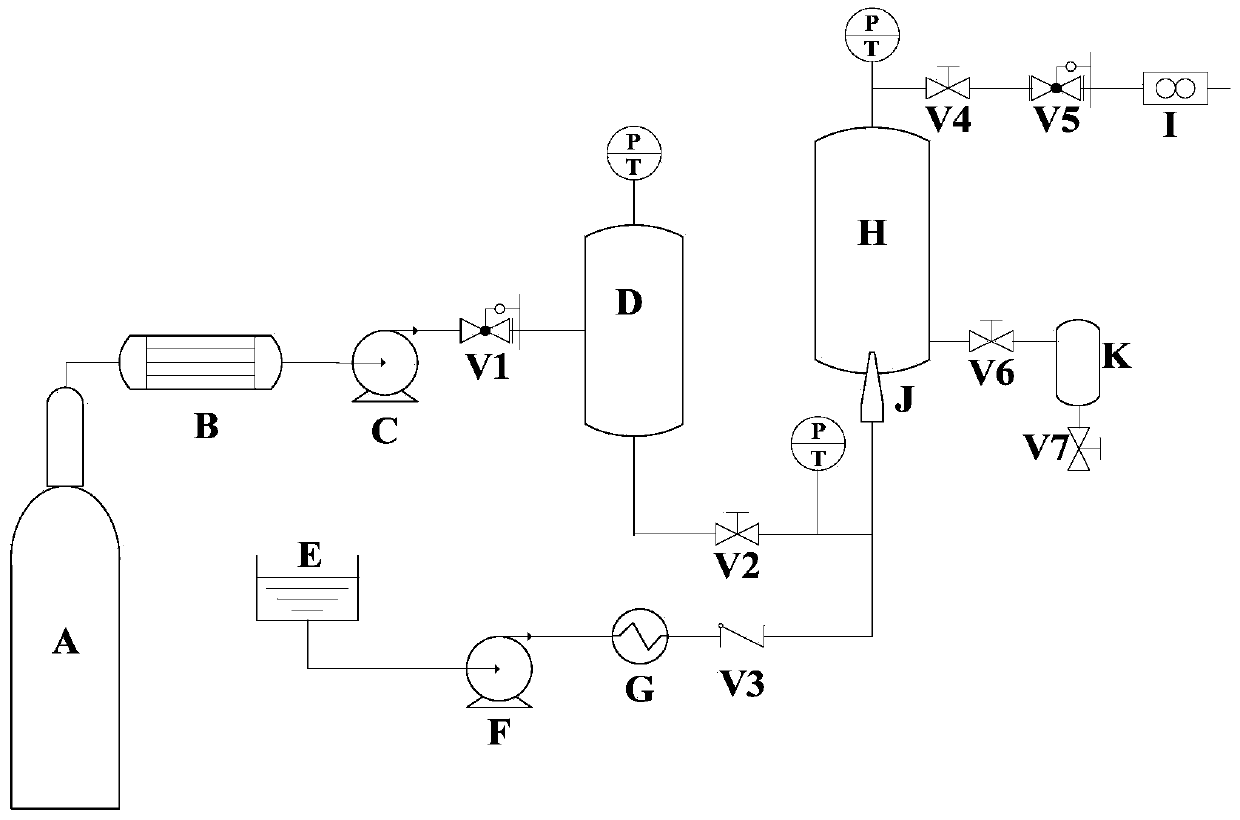

Image

Examples

Embodiment 1

[0036] The raw materials and medicaments used are: silica wet gel obtained by sol-gel method provided by a certain factory, absolute ethanol (Sinopharm Chemical Reagent Co., Ltd., analytically pure), CO 2 (Provided by Linde Gas (Xiamen) Co., Ltd., purity ≥99.9%).

[0037] When the pressure in front of the nozzle is 12MPa, the pre-expansion temperature is 60°C, the diameter of the nozzle is 250μm, the pressure of the drying kettle is 8MPa, the temperature of the drying kettle is 60°C, the solid content in the wet gel is 7.5%, and the mass ratio of ethanol to water is 4.7, When the flow rate of the wet gel is 1.0ml / min, continuous discharge can be carried out. The solvent content of the obtained silica mesoporous powder material is 2.78%, and the BET specific surface area is 237m 2 / g, the pore volume is 1.6cm 3 / g, the pore size is 30.7nm, the average particle size is 11.5μm, and the bulk density is 0.0463g / cm 3 .

Embodiment 2

[0039] The raw materials and medicament used are the same as in Example 1. When the pressure before the nozzle is 12MPa, the pre-expansion temperature is 60°C, the diameter of the nozzle is 250μm, the pressure of the drying kettle is 10MPa, the temperature of the drying kettle is 60°C, the solid content in the wet gel is 7.5%, and the mass ratio of ethanol to water is 4.7 , when the flow rate of the wet gel is 1.0ml / min, continuous discharge can be carried out, the solvent content of the obtained silica mesoporous powder material is 2.50%, and the BET specific surface area is 240m 2 / g, the pore volume is 1.7cm 3 / g, the pore size is 34.0nm, the average particle size is 13.6μm, and the bulk density is 0.0462g / cm 3 .

Embodiment 3

[0041] The raw materials and medicament used are the same as in Example 1. When the pressure before the nozzle is 12MPa, the pre-expansion temperature is 70°C, the diameter of the nozzle is 250μm, the pressure of the drying kettle is 10MPa, the temperature of the drying kettle is 70°C, the solid content in the wet gel is 7.5%, and the mass ratio of ethanol to water is 4.7 , when the flow rate of the wet gel is 1.0ml / min, continuous discharge can be carried out, the solvent content of the obtained silica mesoporous powder material is 1.26%, and the BET specific surface area is 233m 2 / g, the pore volume is 2.1cm 3 / g, the pore size is 38.3nm, the average particle size is 14.6μm, and the bulk density is 0.0484g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com