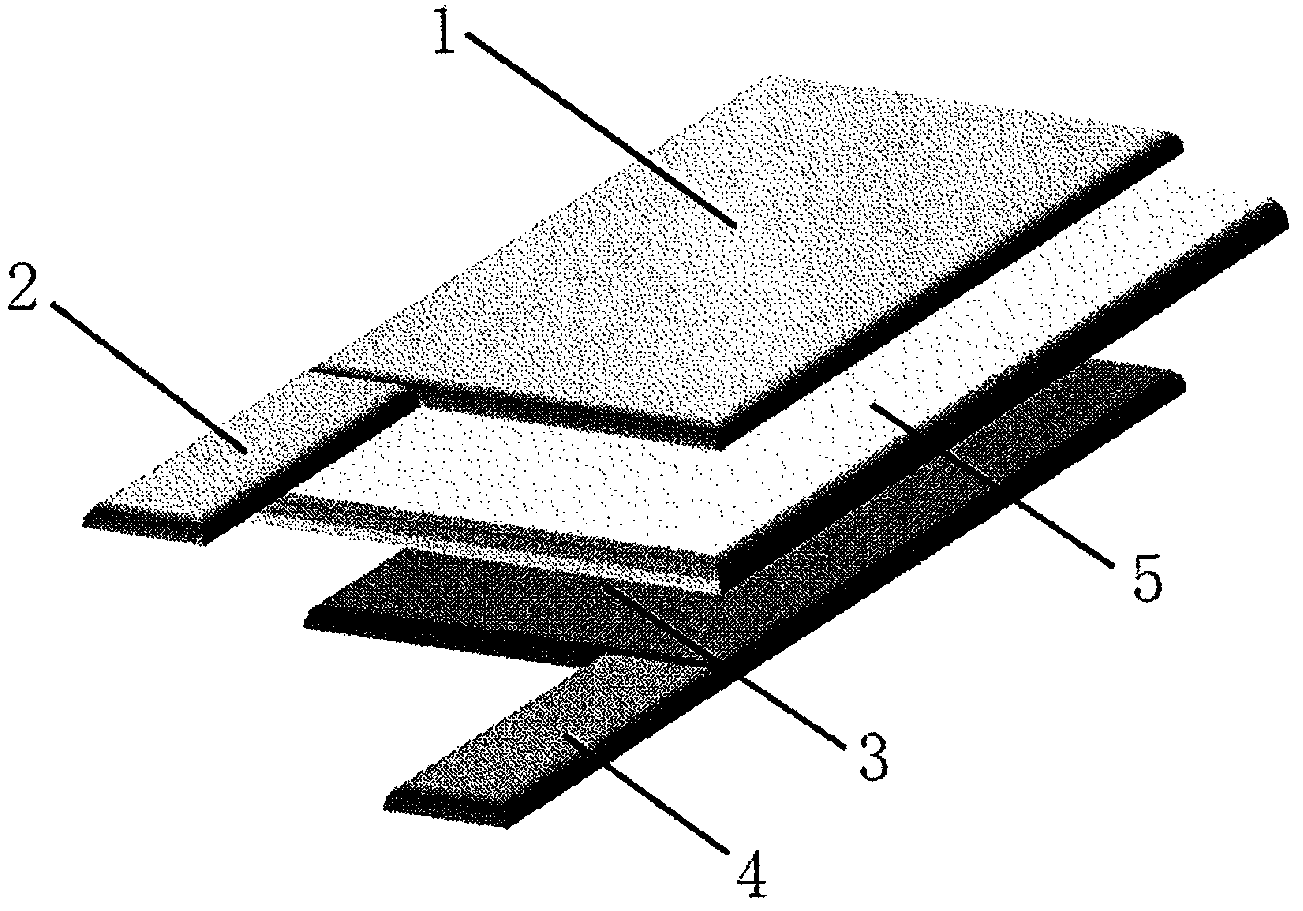

Porous polymer membrane, preparation method thereof and application of porous polymer membrane as gel polymer electrolyte

A porous membrane and polymer technology, applied in the field of polymer film preparation and application, can solve the problems of poor mechanical properties of electrolytes, decreased mechanical properties, unfavorable ion conduction, etc., and achieve improved compatibility, high mechanical strength, and chemical stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

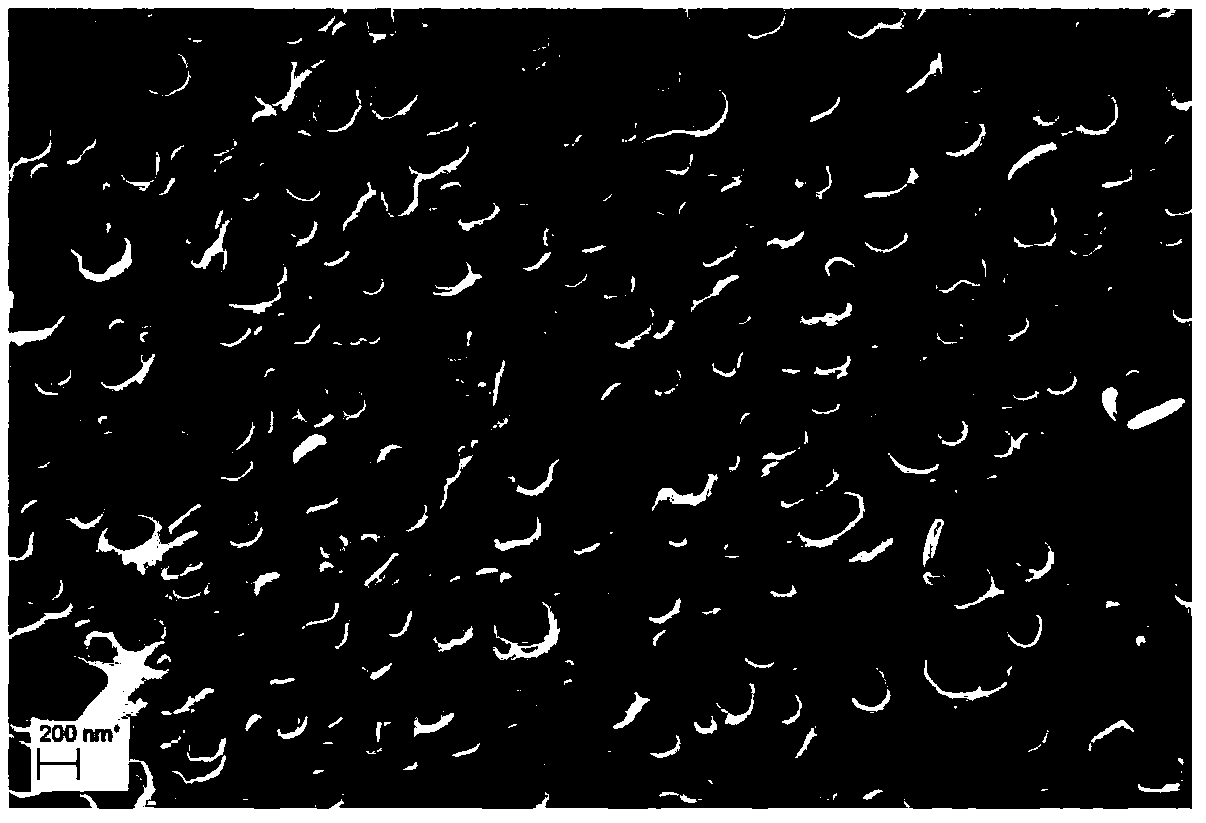

[0049] Dissolve 0.1015g polyvinyl formal (PVFM) in 1.0125g N-methylpyrrolidone (NMP), stir magnetically at 45°C until PVFM is completely dissolved, add 0.0300g 4,4'-diphenylmethane diisocyanate to the solution (MDI), stirred at 75°C for 30 minutes, then added dropwise 0.1295g of deionized water as a non-solvent for polyvinyl acetal and its polyurethane products, white micelles were precipitated, and the white micelles could be dissolved after stirring, and continued magnetic stirring After 30 minutes, the mixed solution was prepared. The mixed solutions were coated and immersed in deionized water to prepare a porous film, and the obtained porous film was dried for 1 hour. The method of drying the porous membrane may be, for example, but not limited to, placing the porous membrane at 30° C. to 60° C., and drying by blowing air or vacuum. figure 2 It is the microscopic morphology of the PVFM polymer porous membrane prepared in Example 1, and the uniformly distributed connected...

Embodiment 2

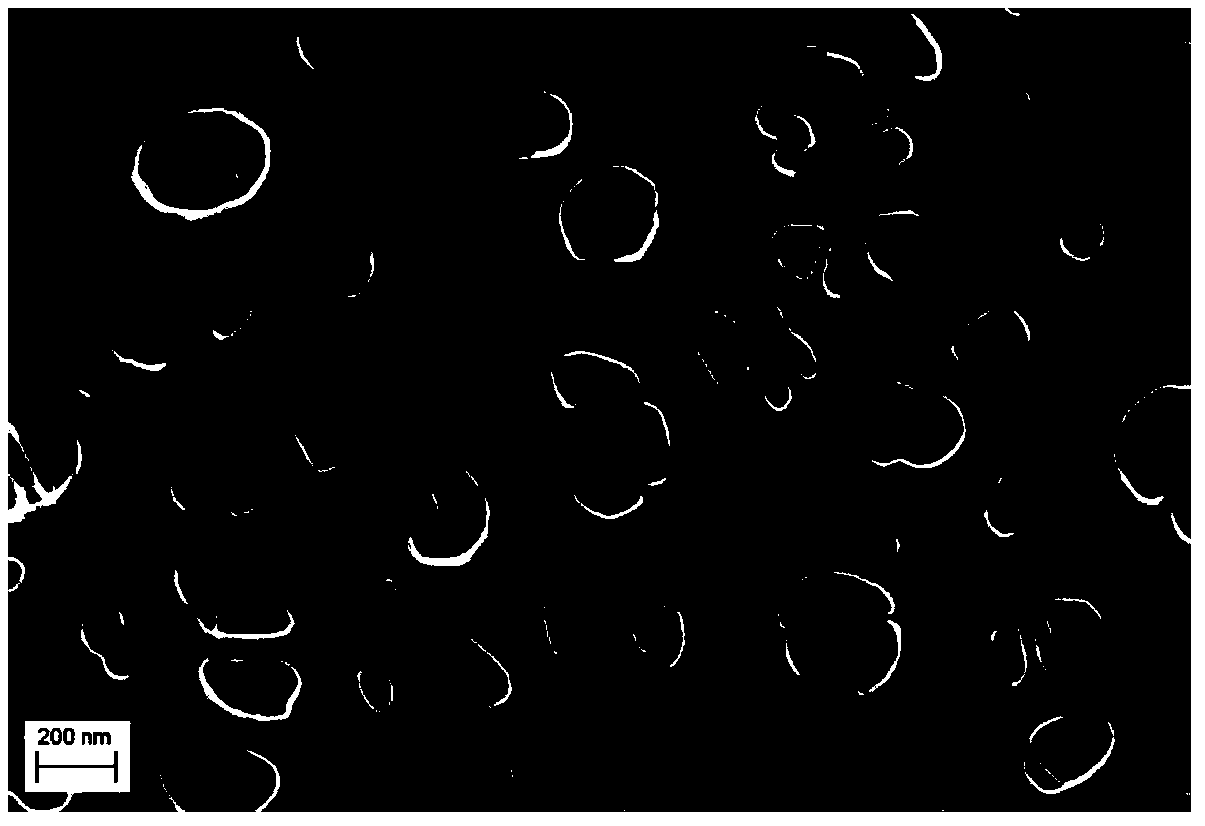

[0051] Dissolve 0.1049g polyvinyl butyral (PVB) in 1.9975g N-methylpyrrolidone (NMP), stir magnetically at 45°C until PVB is completely dissolved, add 0.0111g 4,4'-diphenylmethane di For isocyanate (MDI), stir at 75°C for 30 minutes, then add dropwise 0.0971g of deionized water, and white micelles are precipitated, which can be dissolved after stirring. Continue magnetic stirring for 30 minutes, and the mixed solution is prepared. The mixed solutions were coated and immersed in deionized water to prepare a porous film, and the obtained porous film was dried for 1 hour. The method of drying the porous membrane may be, for example, but not limited to, placing the porous membrane at 30° C. to 60° C., and drying by blowing air or vacuum. image 3 It is the microscopic morphology of the PVB polymer porous membrane prepared in Example 2, and the evenly distributed connected pores bring a high liquid absorption rate of 610%. The high liquid absorption rate and high chemical stabilit...

Embodiment 3

[0053] Dissolve 0.1012g polyvinyl formal (PVFM) in 1.0343g N-methylpyrrolidone (NMP), stir magnetically at 45°C until PVFM is completely dissolved, add 0.0315g 4,4'-diphenylmethane diisocyanate to the solution (MDI), stirred at 75°C for 30 minutes, then added dropwise 0.0114 g of deionized water, and white micelles were precipitated, which could be dissolved after stirring. Continue magnetic stirring for 30 minutes, and the mixed solution was prepared. The mixed solutions were coated and immersed in deionized water to prepare a porous film, and the obtained porous film was dried for 1 hour. The method of drying the porous membrane may be, for example, but not limited to, placing the porous membrane at 30° C. to 60° C., and drying by blowing air or vacuum. The synthetic PVFM polymer porous membrane prepared in Example 3 has a high liquid absorption rate of 411% and high chemical stability, which provides a prerequisite for the formation of a stable gel electrolyte system and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrochemical stability window | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com