A alloy key coincidence and its preparation method and application

A technology of alloy bonding and bonding wire, which is applied in the direction of circuits, electric solid devices, semiconductor devices, etc., can solve the problems of unsatisfactory welding effect and easy disconnection of silver alloy wires, and achieve the requirements of ball planting welding without difficulty The effect of broken wire and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

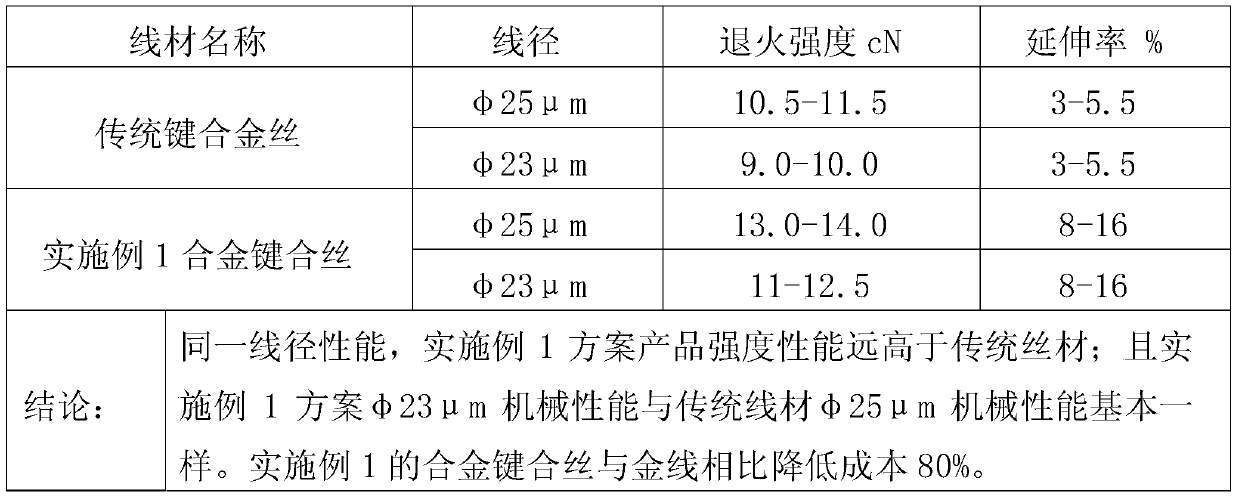

Embodiment 1

[0035] The invention provides an alloy bonding wire. The composition and weight content of the alloy bonding wire are: 5wt% of 5N gold, 2wt% of aluminum, 1wt% of nickel, 91.99wt% of 5N silver, and about 0.01wt% of trace metal raw materials;

[0036] The added content of trace metal raw materials is as follows:

[0037] 5ppm≤Calcium≤20ppm

[0038] 2ppm≤rhodium≤10ppm

[0039] 20ppm≤Beryllium≤50ppm

[0040] 5ppm≤cobalt≤10ppm

[0041] 3ppm≤indium≤10ppm

[0042] 5ppm≤selenium≤10ppm.

[0043] Among them, 5N gold refers to gold with a purity of 99.999%; 5N silver refers to silver with a purity of 99.999%.

[0044] The present invention also provides a method for preparing the above-mentioned alloy bonding wire, the method comprising the following steps:

[0045] 1) Put the base material composed of silver, gold, aluminum, nickel and trace metal elements into the furnace for melting and casting to make silver alloy ingot;

[0046] The total charge is 1000g, including 5N silver ...

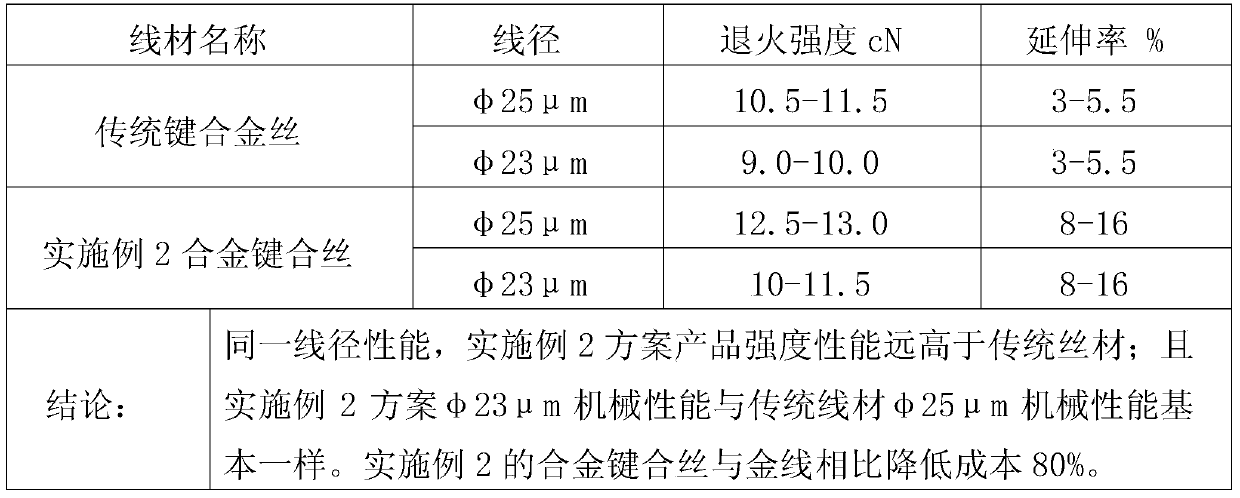

Embodiment 2

[0068] Alloy bonding wire of the present invention, total feeding 1000g, 5N silver material, content 90.49wt%, count 904.9g; 5N gold 8wt%, count 80g; Aluminum 1wt%, count 10g; Nickel 0.5wt%, count 5g; Metal raw material 0.01wt%, 0.1g in total; alloy addition content is as follows:

[0069] 5ppm≤Calcium≤20ppm

[0070] 2ppm≤rhodium≤10ppm

[0071] 20ppm≤Beryllium≤50ppm

[0072] 5ppm≤cobalt≤10ppm

[0073] 3ppm≤indium≤18ppm

[0074] The present invention also provides a method for preparing the above-mentioned alloy bonding wire, the method comprising the following steps:

[0075] 1) Put the base material composed of silver, gold, aluminum, nickel and trace metal elements into the furnace for melting and casting to make silver alloy ingot;

[0076] Total feed 1000g, total feed 1000g, 5N silver material, content 90.49wt%, total 904.9g; 5N gold 8wt%, total 80g; aluminum 1wt%, total 10g; nickel 0.5wt%, total 5g; add trace metal raw materials 0.01% , 0.1g in total; alloy addition...

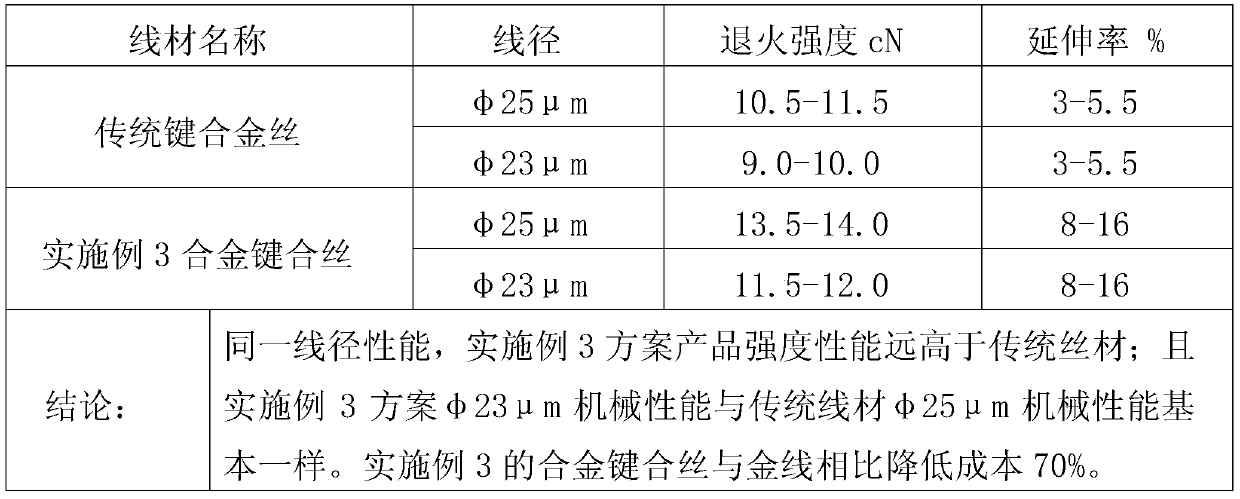

Embodiment 3

[0092] Alloy bonding wire of the present invention, total feeding 1000g, 5N silver material, content 79.99wt%, total 799.9g; 5N gold 10wt%, total 100g; aluminum 5wt%, total 50g; nickel 5wt%, total 50g; add trace metal Raw material 0.01wt%, 0.1g in total; alloy addition content is as follows:

[0093] 5ppm≤Calcium≤10ppm

[0094] 5ppm≤rhodium≤20ppm

[0095] 20ppm≤Beryllium≤50ppm

[0096] 10ppm≤cobalt≤20ppm

[0097] 2ppm≤indium≤5ppm

[0098] The present invention also provides a method for preparing the above-mentioned alloy bonding wire, the method comprising the following steps:

[0099] 1) Put the base material composed of silver, gold, aluminum, nickel and trace metal elements into the furnace for melting and casting to make silver alloy ingot;

[0100] Total feeding 1000g, 5N silver material, content 79.99wt%, 799.9g; 5N gold 10wt%, 100g; aluminum 5wt%, 50g; nickel 5wt%, 50g; add trace metal raw material 0.01%, 0.1g; Alloy addition content is as follows:

[0101] 5ppm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com