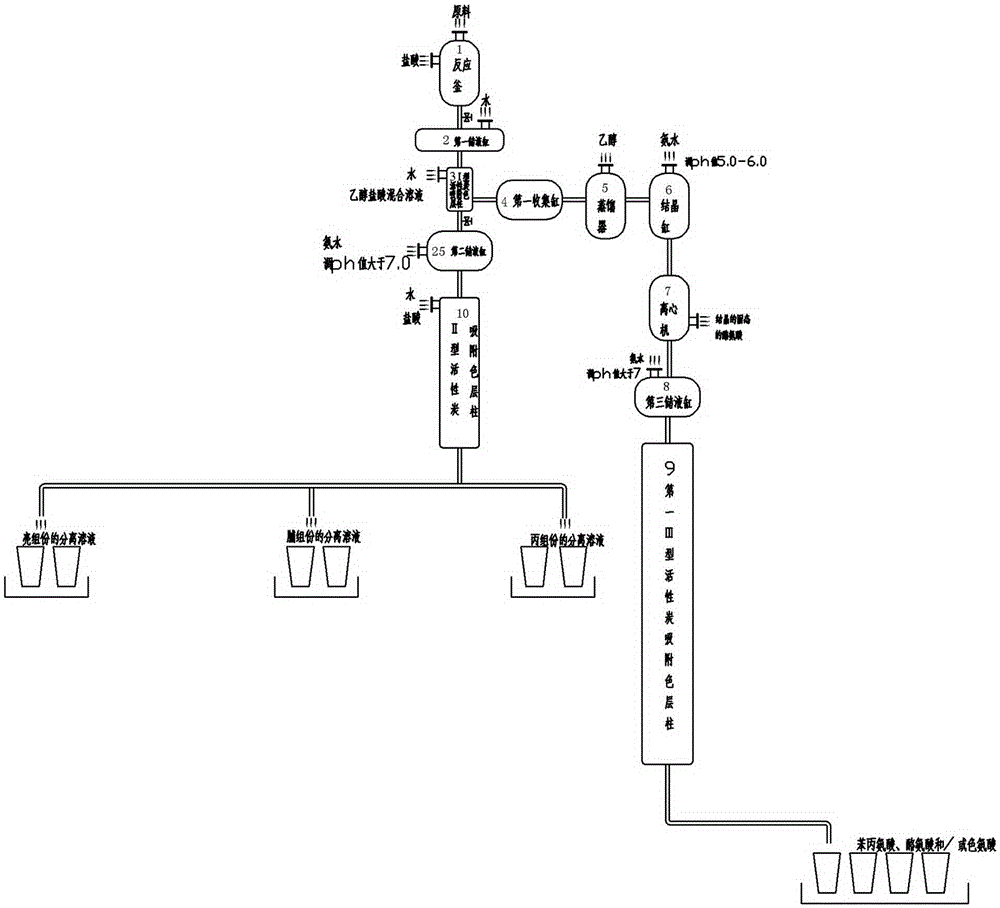

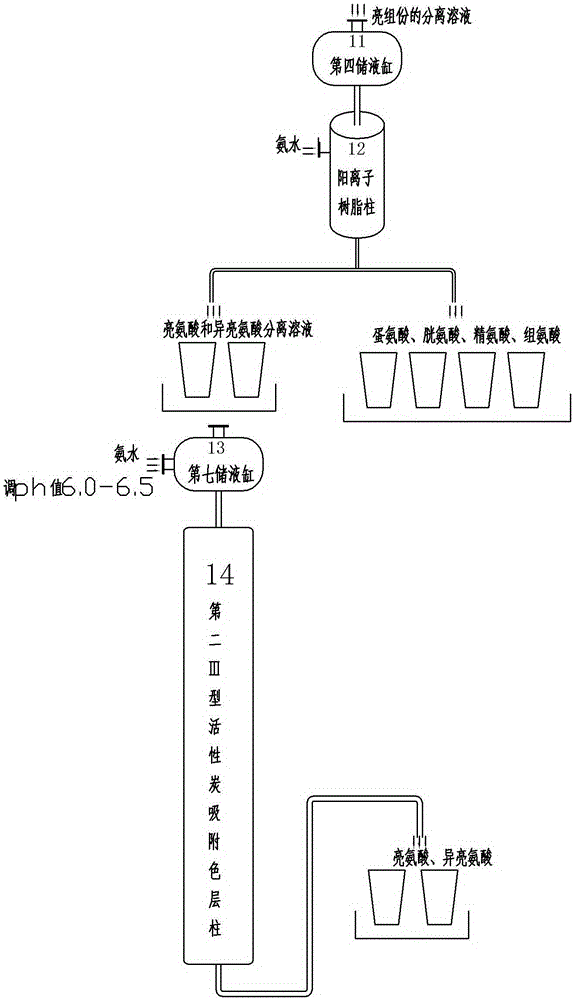

A method and equipment for separating and extracting amino acid products from protein hydrolyzate

A protein and amino acid technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of thioethers, etc., can solve the problem of no separation and extraction, and achieve the effect of expanding the degree of separation, high yield and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Put 100 grams of pig blood meal protein into an 800mL round bottom flask, add 300mL of 6mol / L concentrated hydrochloric acid, heat to above 110°C, hydrolyze for 20 hours, collect the protein hydrolyzate, dilute it with water, let it flow through a 10cm diameter , 15cm high, type I activated carbon adsorption chromatographic column with granular activated carbon body inside, and then wash the chromatographic column with clean water, and use 0.1mol / L hydrochloric acid to prepare a mixed solution of ethanol hydrochloric acid with 50% ethanol concentration to flow through the chromatographic column. After layering the column, wash the chromatographic column with water, combine the water washing liquid and the washing liquid after washing with the ethanol hydrochloric acid mixed solution to obtain the collected liquid, and recover the ethanol by distillation to obtain 150mL protein concentrate and 128mL ethanol solution with a volume percentage of less than 30%. , then use 2m...

Embodiment 2

[0036]Put 100 grams of duck feathers in an 800mL round bottom flask, add 200mL of 10mol / L concentrated hydrochloric acid, heat to above 110°C, hydrolyze for 7 hours, collect the protein hydrolyzate, dilute with water, let it flow through a 10cm in diameter, high 15cm, type I activated carbon adsorption chromatographic column with granular activated carbon body inside, and then wash the chromatographic column with water, and use 0.1mol / L hydrochloric acid to make a mixed solution of ethanol and hydrochloric acid with 50% ethanol concentration to flow through the chromatographic column Finally, wash the chromatographic column with clear water, combine the washing liquid and the washing liquid after washing with the ethanol hydrochloric acid mixed solution to obtain the collected liquid, after distilling and recovering the ethanol, obtain 150mL protein concentrate, and then adjust the protein concentration with 2mol / L ammonia solution The pH value of liquid reaches 5.6, and static...

Embodiment 3

[0039] Put 100 grams of unpeeled rapeseed cake in an 800mL round bottom flask, add 300mL of water to soak for 6 hours, and grind it into a paste, collect the rapeseed cake slurry, adjust the pH value to 7.0, and add 500 units / mL of bacteria Protease was hydrolyzed at 40°C for 3 hours, heated to 100°C and kept for 0.5 hours to inactivate the enzyme, adjusted the pH to 5.0, added 400 units / mL mycoprotease, hydrolyzed at 32°C for 3 hours, raised to 100°C and maintained for 0.5 hours to inactivate the enzyme; Then add 50 units / mL papain and hydrolyze at 31°C for 3 hours, raise the temperature to 100°C and keep it for 0.5 hours to inactivate the enzyme; then add 400 units / mL mycoprotease and hydrolyze at 32°C for 3 hours, filter with Buchner funnel to completely inactivate the enzyme , to obtain the amino acid mixed solution generated by enzymatic hydrolysis; adjust the pH value to 2.5 with 0.1mol / L hydrochloric acid, let it flow through a type I activated carbon adsorption chromato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com