Square diamond wire saw device for polycrystalline silicon ingot

A technology of diamond wire saw and polycrystalline silicon ingot, which is used in fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of low cutting efficiency, difficulty in changing wires, and scratches on the cutting surface, and achieve good cutting. Surface flatness and roughness, easy and fast replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

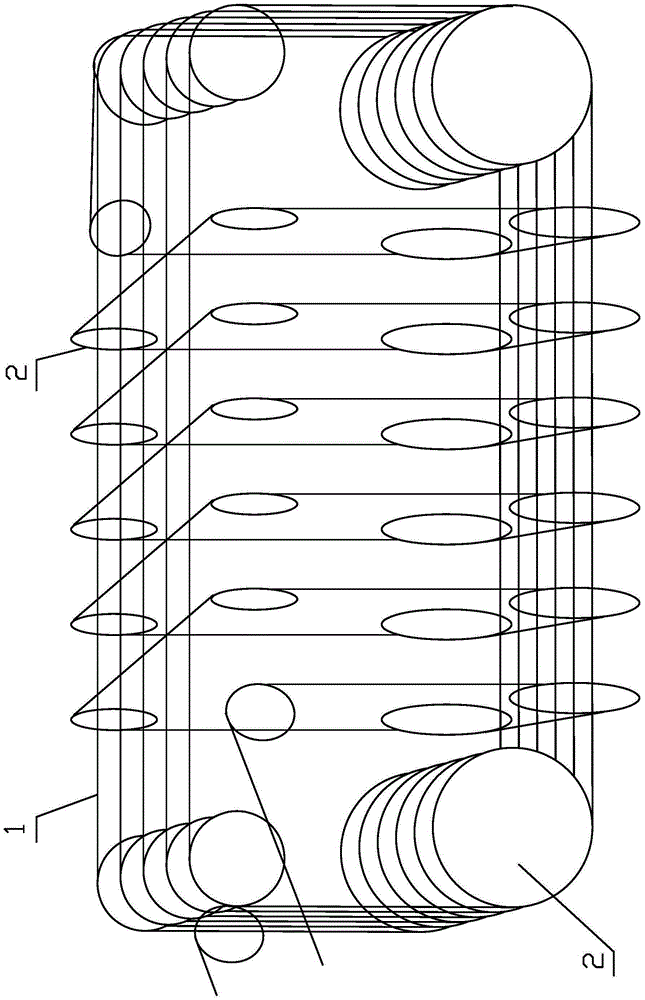

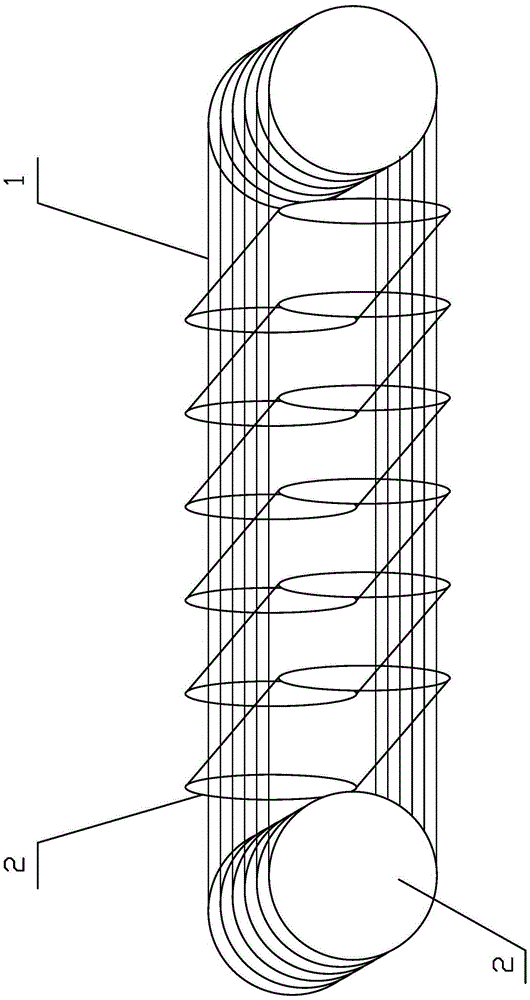

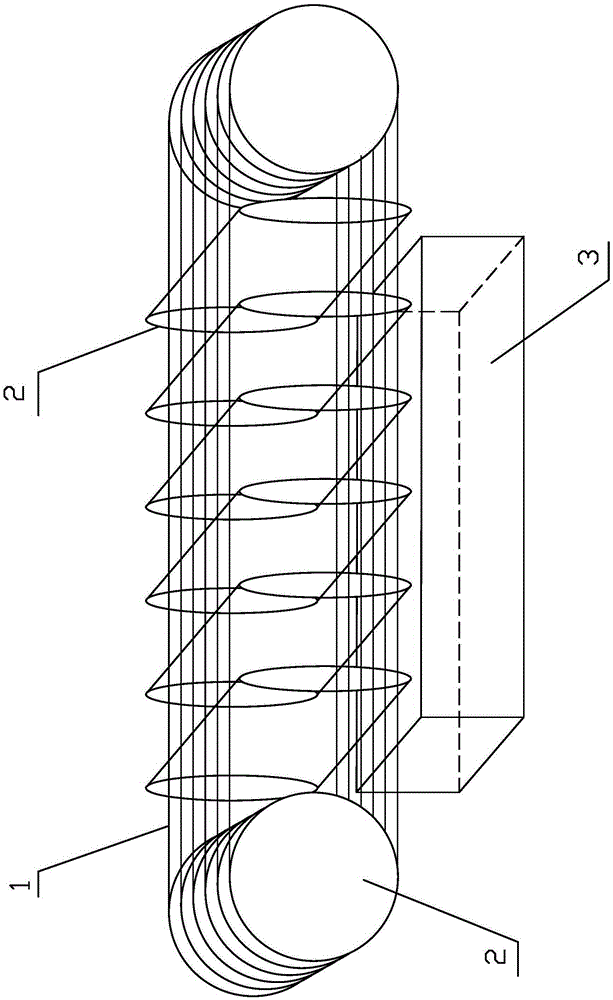

[0027] The polycrystalline silicon ingot square diamond wire saw device of the present invention includes a diamond wire saw mechanism, and the diamond wire saw mechanism includes an upper and a lower layer of grid-shaped cutting nets. The diamond saw wire 1 line group and another group of Y-direction diamond saw wire 1 line groups on the Y-direction cutting surface are vertically intersected, the X-direction diamond saw wire 1 line group is on the same plane, and the Y-direction diamond saw wire The silk 1 wire family is on another plane, and the distance between the two planes is 5mm to 20mm, such as figure 2 , Figure 4 shown.

[0028] A group of cutting surfaces in the X direction are parallel and equidistant to each other, and are formed by several annular diamond saw wires 1, and the several annular diamond s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com