High stability nanogold catalyst and preparation method thereof

A high-stability, nano-gold technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve long reaction time, high reaction temperature, preparation process Complex problems, to achieve the effect of high activity and stability, good repeatability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of a highly stable nano-gold catalyst, the steps are as follows:

[0041] Dissolve 1.1 grams of polyvinylpyrrolidone, 0.4 grams of silver nitrate, 3.2 milligrams of copper chloride, 720 microliters of 25% ammonia, 0.16 grams of chloroauric acid, and 0.16 grams of chloroplatinic acid in 32 milliliters of ethylene glycol , to prepare mixed solution A;

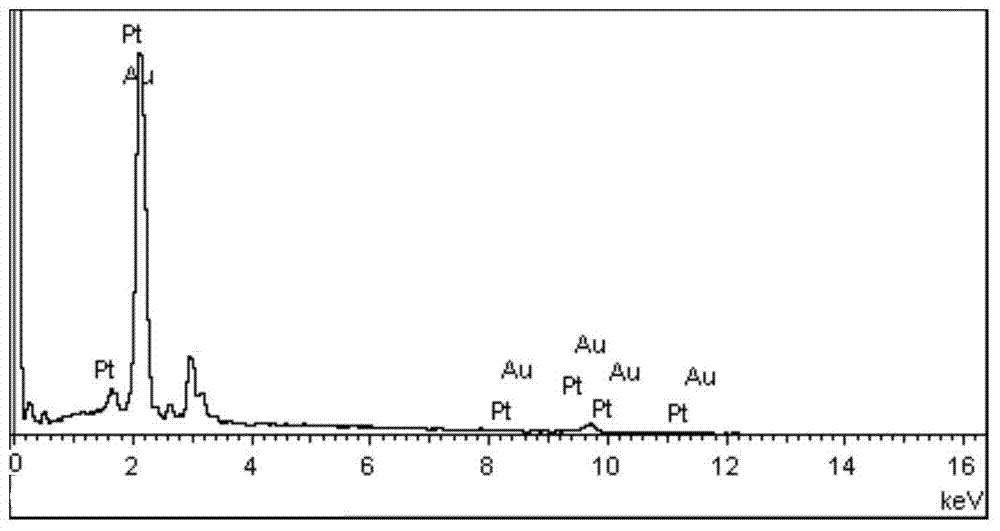

[0042]Transfer the mixed solution A to a reaction kettle, then place it in an oven, react at 200°C for 240 minutes, stop heating and cool to room temperature naturally, centrifuge at 13,000 rpm for 5 minutes, take the precipitate and mix it with 100 ml of ethanol, 13,000 Centrifuge for 5 minutes at rpm, mix the precipitate with 100 ml of water, centrifuge at 13,000 rpm for 5 minutes, and collect the precipitate to obtain gold / silver / platinum layered structure nanoparticles.

[0043] The above-mentioned gold / silver / platinum layered structure nanoparticles were redispersed in 20 milliliters of water to ...

Embodiment 2

[0049] A preparation method of a highly stable nano-gold catalyst, the steps are as follows:

[0050] Dissolve 1.1 grams of polyvinylpyrrolidone, 0.4 grams of silver nitrate, 3.2 milligrams of copper chloride, 720 microliters of 25% ammonia water, 0.12 grams of chloroauric acid, and 0.12 grams of chloroplatinic acid in 32 milliliters of ethylene glycol , to prepare mixed solution A;

[0051] Transfer the mixed solution A to a reaction kettle, then place it in an oven, react at 200°C for 240 minutes, stop heating and cool to room temperature naturally, centrifuge at 13,000 rpm for 5 minutes, take the precipitate and mix it with 100 ml of ethanol, 13,000 Centrifuge for 5 minutes at rpm, mix the precipitate with 100 ml of water, centrifuge at 13,000 rpm for 5 minutes, and collect the precipitate to obtain gold / silver / platinum layered structure nanoparticles.

[0052] The above-mentioned gold / silver / platinum layered structure nanoparticles were redispersed in 40 milliliters of wa...

Embodiment 3

[0055] A preparation method of a highly stable nano-gold catalyst, the steps are as follows:

[0056] Dissolve 1.1 grams of polyvinylpyrrolidone, 0.4 grams of silver nitrate, 3.2 milligrams of copper chloride, 720 microliters of ammonia water with a mass concentration of 25%, 0.16 grams of chloroauric acid, and 0.16 grams of chloroplatinic acid in 32 milliliters of dimethylformamide In, mixed solution A was prepared;

[0057] Transfer the mixed solution A to a reaction kettle, then place it in an oven, react at 160°C for 240 minutes, stop heating and cool to room temperature naturally, centrifuge at 13,000 rpm for 5 minutes, take the precipitate and mix it with 100 ml of ethanol, 13,000 Centrifuge for 5 minutes at rpm, mix the precipitate with 100 ml of water, centrifuge at 13,000 rpm for 5 minutes, and collect the precipitate to obtain gold / silver / platinum layered structure nanoparticles.

[0058] The above-mentioned gold / silver / platinum nanoparticle with layered structure w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com