Microwave response shape memory polymer composite material and preparation method thereof

A technology of memory polymers and composite materials, which is applied in the preparation of shape memory polymer composite materials and in the field of shape memory polymer composite materials, can solve problems such as inconvenience, achieve the effect of broadening types and improving thermomechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

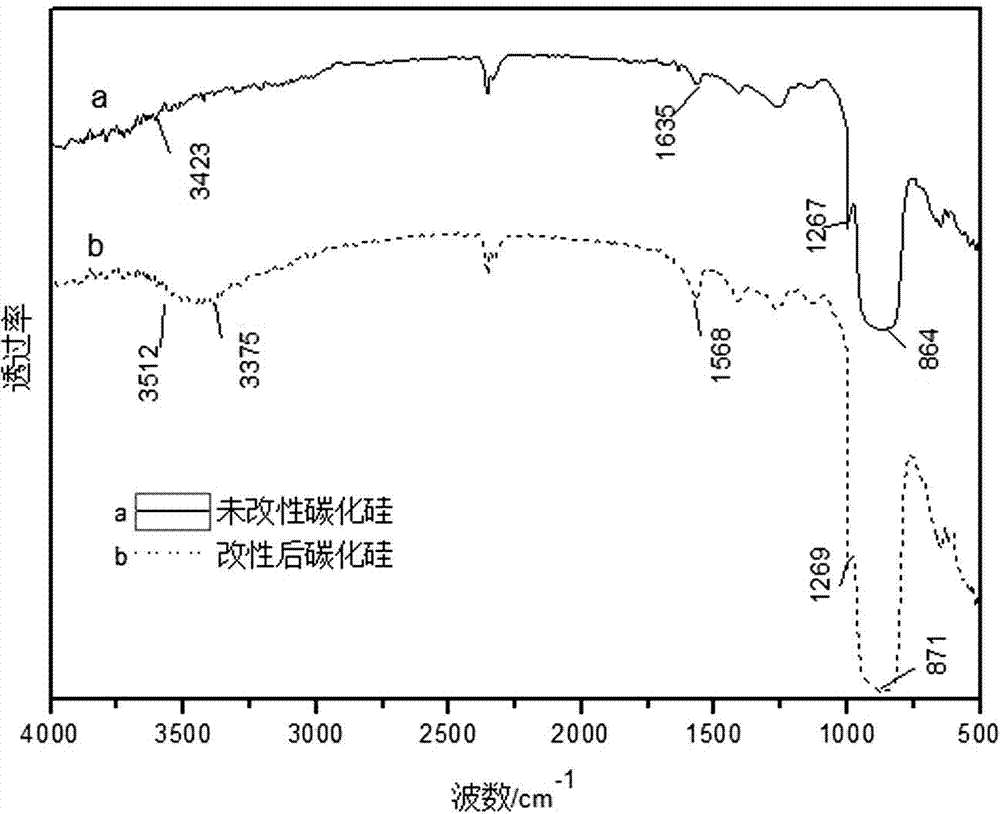

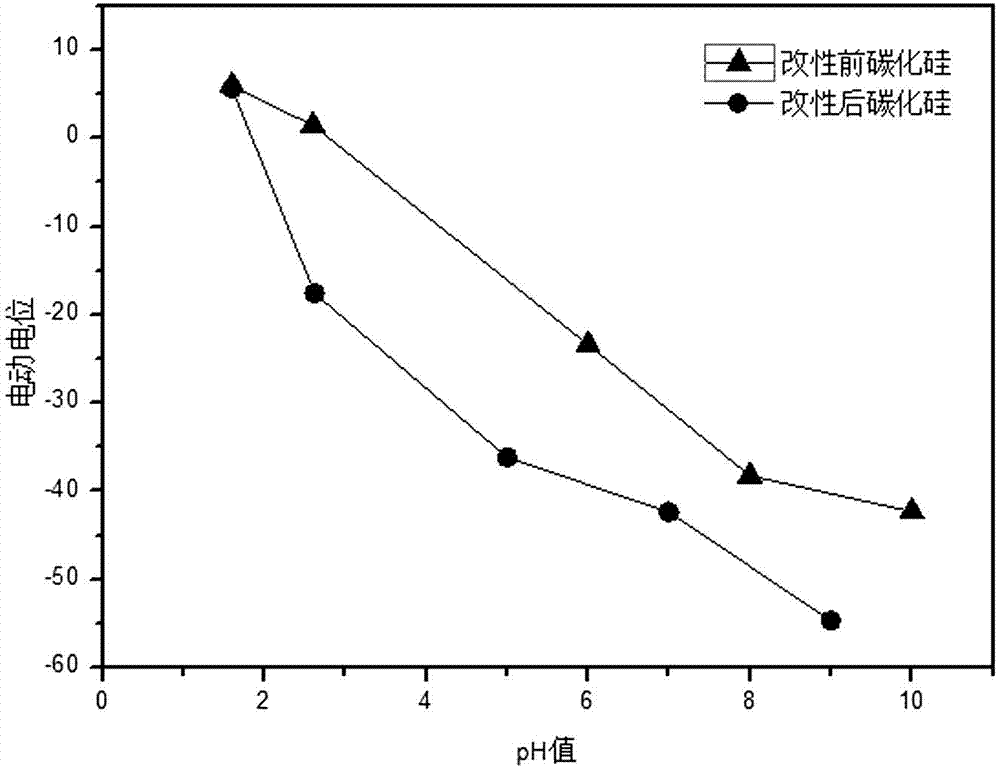

[0033] Take 12g of nano-silicon carbide, add it to 120mL of 10% hydrochloric acid aqueous solution, stir for 24h, wash and filter repeatedly until the filtrate is neutral, and dry at a constant temperature of 120°C. Take 10 g of dried silicon carbide powder and add it to 100 mL of toluene, heat up to 50°C and stir for 1 h, add 0.3 g of KH550 dropwise, and stir for 2 h. ℃ drying in an oven for 12 hours to obtain modified silicon carbide.

[0034] Take 5 g of polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 99% and add it to 100 mL of water, and dissolve it at 98°C for 6 hours to obtain a 5% aqueous solution of polyvinyl alcohol. After the solution was cooled to room temperature, the pH value of the solution was adjusted to 3 with hydrochloric acid solution.

[0035] Disperse 0.5g of modified silicon carbide in 10mL of water, mix it in 100mL of polyvinyl alcohol aqueous solution, add 0.05g of glutaraldehyde and stir for 3 minutes, inject ...

Embodiment 2

[0038] Take 12g of nano-silicon carbide, add it to 120mL of 8% hydrochloric acid aqueous solution, stir for 24h, wash and filter repeatedly until the filtrate is neutral, and dry at a constant temperature of 120°C. Take 10 g of dried silicon carbide powder, add it to 100 mL of toluene, raise the temperature to 60°C and stir for 4 h, add 0.1 g of KH560 dropwise, and stir for 4 h. Dry in an oven at 105°C for 12h.

[0039] Take 9g of polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 88% and add it to 100mL of water, and dissolve it at 98°C for 6 hours to obtain a 9% aqueous solution of polyvinyl alcohol. After the solution was cooled to room temperature, the pH value of the solution was adjusted to 4 with hydrochloric acid solution.

[0040] Disperse 0.3g of modified silicon carbide in 10mL of water, mix it in 100mL of polyvinyl alcohol aqueous solution, add 0.1g of glutaraldehyde and stir for 3 minutes, inject the mixed solution into a hol...

Embodiment 3

[0043] Take 12g of nano-silicon carbide, add it to 120mL of 5% hydrochloric acid aqueous solution, stir for 24h, wash and filter repeatedly until the filtrate is neutral, and dry at a constant temperature of 120°C. Take 10 g of dried silicon carbide powder, add it to 100 mL of toluene, raise the temperature to 70°C and stir for 1 h, add 0.5 g of KH590 dropwise, and stir for 6 h. Dry in an oven at 105°C for 12h.

[0044] Take 6 g of polyvinyl alcohol with a degree of polymerization of 500 and a degree of alcoholysis of 88%, add it to 100 mL of water, and dissolve it at 98°C for 6 hours to obtain a 6% aqueous solution of polyvinyl alcohol. After the solution was cooled to room temperature, the pH value of the solution was adjusted to 3 with hydrochloric acid solution.

[0045] Disperse 0.1g of modified silicon carbide in 10mL of water, mix it in 100mL of polyvinyl alcohol aqueous solution, add 0.2g of glutaraldehyde and stir for 3 minutes, inject the mixed solution into a hollo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com