Long-life, safe and reliable forging cast iron mold for iron casting machine and manufacturing method thereof

A technology of cast iron mold and cast iron machine, which is applied in the direction of manufacturing tools, foundry workshops, casting equipment, etc., to reduce the speed and degree of cracks, improve the use effect, and improve the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

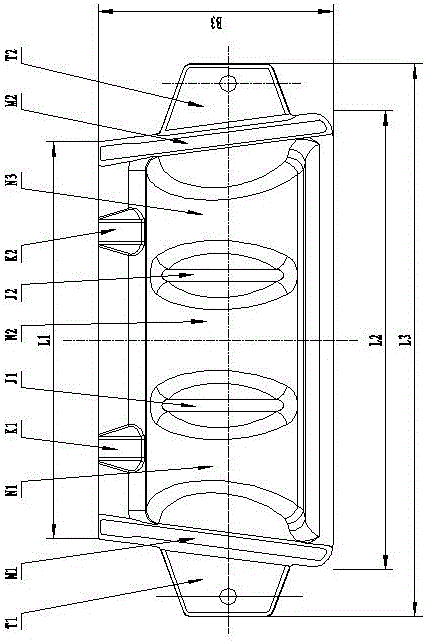

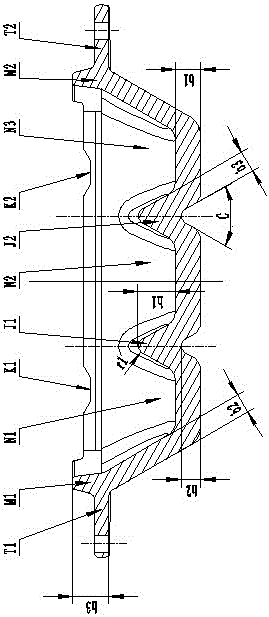

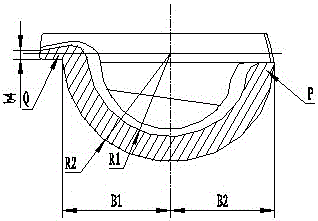

[0039] The forged cast iron mold is integrally formed by the forging process. There are two partition ribs (J1 and J2) inside the forged cast iron mold. The partition ribs divide the internal cavity of the forged cast iron mold into three molding cavities (N1, N2, N3). The forged cast iron mold is installed on the cast iron machine to overlap each other, and moves from bottom to top (F). The lower end of the forged cast iron mold along the direction of molten iron is provided with a lap joint (Q), and two overflows are provided on the outer edge of the lap joint. Mouth (K1 and K2), the two sides of the forged cast iron mold are provided with molten iron guards (M1 and M2) and ears (T1 and T2) connected with the chain plate. The thickness b1 of the bottom of the forged cast iron mold is 40mm, the thickness b2 of the outer slope is 35mm, the thickness b3 of the rib forming is 35mm, the angle C of the slope is 55°, the top fillet r1 is 12mm, and the thickness b4 of the lap joint e...

Embodiment 2

[0041] The material of the forged cast iron mold is high-quality low-carbon structural steel plate Q235 with a thickness of 60mm. The forged cast iron mold adopts a special intermediate frequency heating furnace and a heating coil made according to the shape of the blank. The heating time is 9 minutes and the heating temperature is 1200 ℃, the forged cast iron mold adopts a matching special trimming mold, and the formed forged cast iron mold does not need subsequent manual processing.

Embodiment 3

[0043] The forged cast iron mold is integrally formed by the forging process. There are three ribs inside the forged cast iron mold. The ribs divide the inner mold cavity of the forged cast iron mold into four molding cavities. The forged cast iron mold is installed on the cast iron machine to overlap each other. While moving upward (F), the lower end of the forged cast iron mold along the direction of the molten iron is provided with a splice nozzle (Q). and M2) and the ears (T1 and T2) connected with the chain plate, there are 4 connecting bolt holes. The thickness b1 of the bottom of the forged cast iron mold is 45mm, the thickness b2 of the outer slope is 38mm, the thickness b3 of the rib forming is 40mm, the angle C of the slope is 65°, the top fillet r1 is 15mm, and the thickness b4 of the lap joint end is 20mm. The inner wall arc R1 is 130mm, the outer wall arc R2 is 175mm, and the bottom surface of the longitudinal section is an arc surface. The forged cast iron mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com